Soil nutrient activator suitable for saline-alkali land improvement and preparation method thereof

An activator, a technology for saline-alkali land, applied in the field of soil nutrient activator and its preparation, agricultural fertilizer processing, can solve the problems of poor improvement effect, serious enrichment of nitrogen, phosphorus and potassium, and limited application of biological inoculants, etc. Air permeability, promoting root growth, high fruit set rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

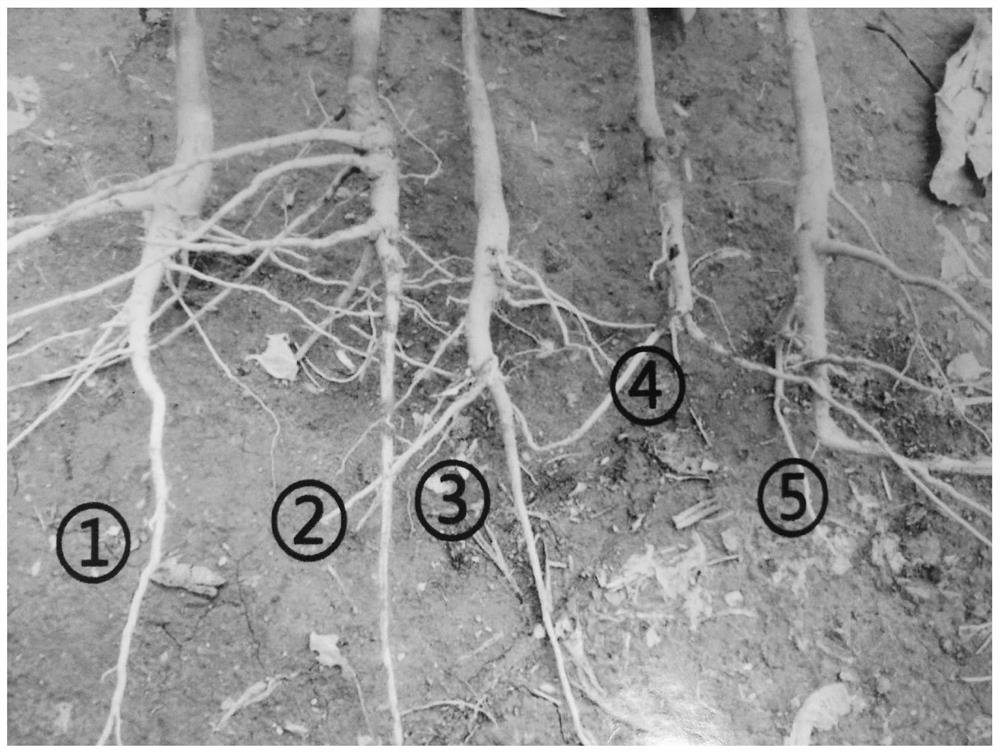

Image

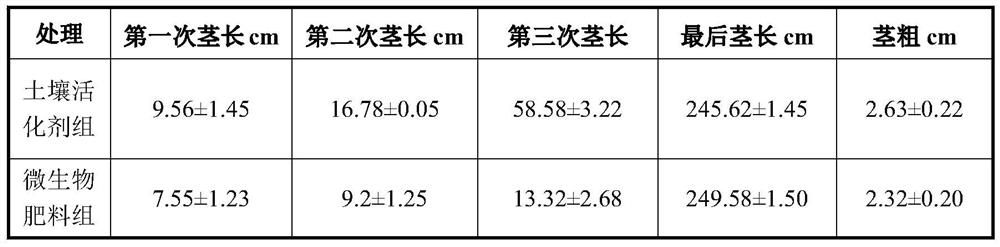

Examples

Embodiment 1

[0029]Firstly prepare the compound bacterial agent, respectively ferment Bacillus subtilis, Bacillus megaterium, and phosphate solubilizing bacteria in industrial fermentation tanks, and obtain the fermented liquid according to the weight ratio of Bacillus phleus, Bacillus megaterium, and phosphate solubilizing bacteria in a ratio of 2:1:2 Compounded and concentrated at 25°C to obtain a complex microbial agent. Mix 150kg of bamboo charcoal, 180kg of peat and 210kg of coconut shell activated carbon and then air-dry them. After air-drying, make 0.2mm powder and add 300kg of HNO at room temperature 3 solution and 450kgH 2 o 2 The solution is oxidized, and after treatment, water is added in a certain proportion to obtain the mixed material A. Then 54kg of humus and 110kg of vermicompost were pulverized, and then 28kg of bamboo vinegar and water were added in proportion, so that the water content of the raw material was controlled between 35%, and piled up and fermented for 5 day...

Embodiment 2

[0031] Bacillus subtilis and phosphate solubilizing bacteria are fermented separately in industrial fermentation tanks, and the fermented liquid obtained is compounded according to the weight ratio of Bacillus phleus and phosphate solubilizing bacteria at a ratio of 2:1, and concentrated at 25°C to obtain a composite bacterial agent. Mix 162kg of bamboo charcoal, 195kg of peat and 230kg of coconut shell activated carbon and then air-dry them. After air-drying, make 0.3mm powder and add 400kg of HNO at room temperature 3 solution and 500kgH 2 o 2 The solution is oxidized, and after treatment, water is added in a certain proportion to obtain the mixed material A. Then 56kg of humus and 110kg of vermicompost were pulverized, and then 32kg of bamboo vinegar and water were added in proportion, so that the water content of the raw material was controlled between 45%, and piled up and fermented for 7 days under the condition of 28°C-32°C to obtain The first fermentation product; th...

Embodiment 3

[0033] Bacillus megaterium and phosphate solubilizing bacteria are fermented separately in industrial fermentation tanks, and the obtained fermentation broth is compounded according to the weight ratio of Bacillus megaterium and phosphate solubilizing bacteria at a ratio of 3:1, and then concentrated at 25°C to obtain a composite bacterial agent. 170kg of bamboo charcoal, 190kg of peat and 235kg of coconut shell activated carbon were mixed and then air-dried. After air-drying, 0.4mm powder was made, and 480kg of HNO was added at room temperature. 3 solution and 480kgH 2 o 2 The solution is oxidized, and after treatment, water is added in a certain proportion to obtain the mixed material A. Then 57kg of leaf humus and 115kg of vermicompost were pulverized, and then 30kg of bamboo vinegar and water were added in proportion to make the water content of the raw materials controlled between 35%, and piled up and fermented for 10 days under the condition of 29°C to obtain the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com