Phase change energy storing material having photo-thermal conversion performance and preparation method of same

A technology of phase-change energy storage materials and light-to-heat conversion materials, which is applied in the direction of heat exchange materials, microsphere preparation, chemical instruments and methods, etc., can solve the problems of climate and season influence, low solar radiation energy density, and direct utilization limitations And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] According to an aspect of the embodiments of the present invention, a phase-change energy storage material I with light-to-heat conversion performance and a preparation method thereof are provided, and the specific steps are as follows:

[0091] (1) Mix the phase change material with an emulsifier and emulsify it at 20-100°C to obtain an emulsion (referred to as core material I), or directly use the phase change material as the inner core (record as core material II);

[0092] (2) Use any one of the following methods (a), (b) and (c) to prepare the shell material and encapsulate the core material I:

[0093] (a) Prepare the organic shell material by any method of in-situ polymerization, interfacial polymerization, suspension polymerization, and complex coacervation: add the solution of the organic polymerization system (referred to as shell solution A) dropwise to the inner core I and keep stirring, the finally obtained shell is an organic material (referred to as shell...

Embodiment 1

[0111] This embodiment provides a phase-change energy storage material with light-to-heat conversion performance, and specifically relates to a phase-change energy storage material I with a light-to-heat conversion material embedded in the shell material B', and its preparation method is as follows:

[0112] (1) Preparation of inner core material I: Weigh 10g of solid paraffin (58-60° C. of melting point) and put it into a three-necked flask and heat and melt it in a water bath at 70° C. (Sodium DodecylSulfate, SDS) was emulsified to obtain an emulsion.

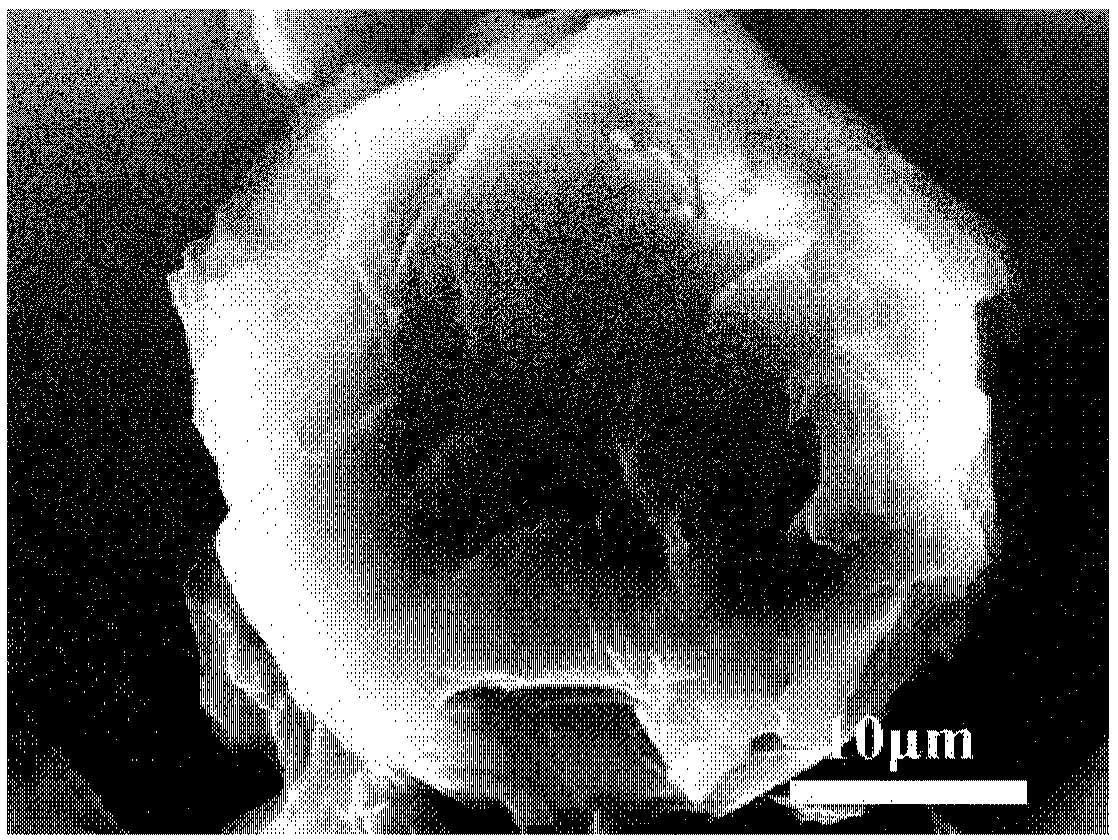

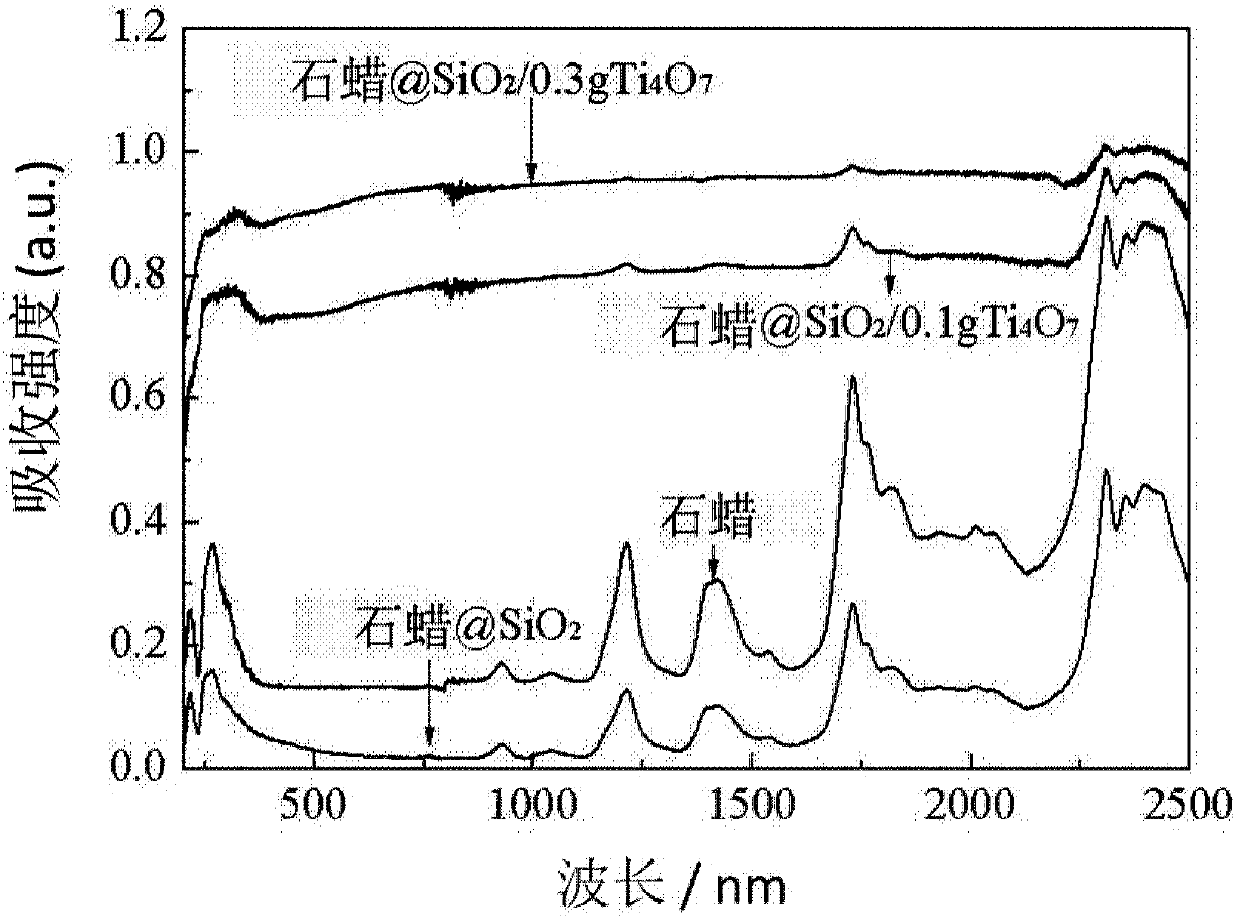

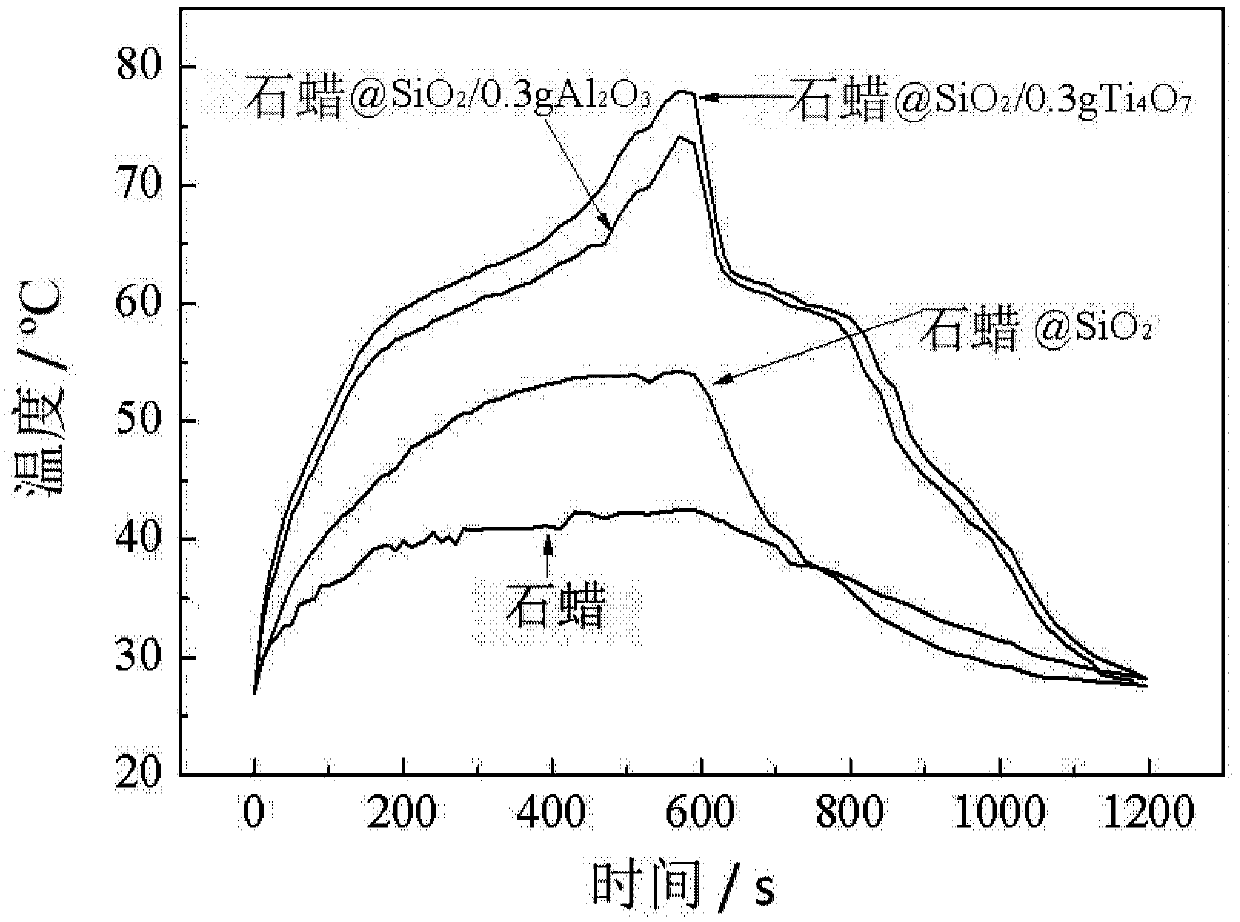

[0113] (2) Prepare shell material B' by sol-gel method and encapsulate inner core material I: mix 20ml tetraethyl orthosilicate, 20ml absolute ethanol, 40ml distilled water and 1ml hydrochloric acid, add 0.1g Ti 4 o 7 Stir the powder for 0.5-1h, then add the mixed solution dropwise into the emulsion obtained in step (1), and continue stirring for 0.5-2h to obtain a shell material of SiO 2 Mosaic Ti 4 o 7 Particle phase ch...

Embodiment 2

[0115] This embodiment provides a phase-change energy storage material with light-to-heat conversion performance, and specifically relates to a phase-change energy storage material I whose inner core material I' contains a light-to-heat conversion material. The preparation method is as follows:

[0116] (1) Preparation of inner core material I': Weigh 10g of solid paraffin (melting point 58-60°C) into a three-necked flask, heat and melt in a water bath at 70°C, emulsify with 150ml of SDS with a mass concentration of 0.3wt%, and obtain Emulsion, add 0.1g Ti 4 o 7 Stir the powder until evenly dispersed in the emulsion.

[0117] (2) Prepare shell material B by sol-gel method and encapsulate inner core material I': mix and stir 20ml tetraethyl orthosilicate, 20ml absolute ethanol, 40ml distilled water and 1ml hydrochloric acid for 0.5-1h, then mix the mixed solution Add dropwise to the above emulsion, continue to stir for 0.5~2h, and the shell material is SiO 2 , the inner core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com