A kind of graphene synergistic without discharge environment-friendly water-based cutting fluid and preparation method thereof

A graphene dispersion liquid and graphene technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of poor anti-rust effect, low bearing capacity, and decline of water-based cutting fluids, and achieve improved cooling performance and anti-corrosion Rust performance, good anti-wear performance and lubricating performance, wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

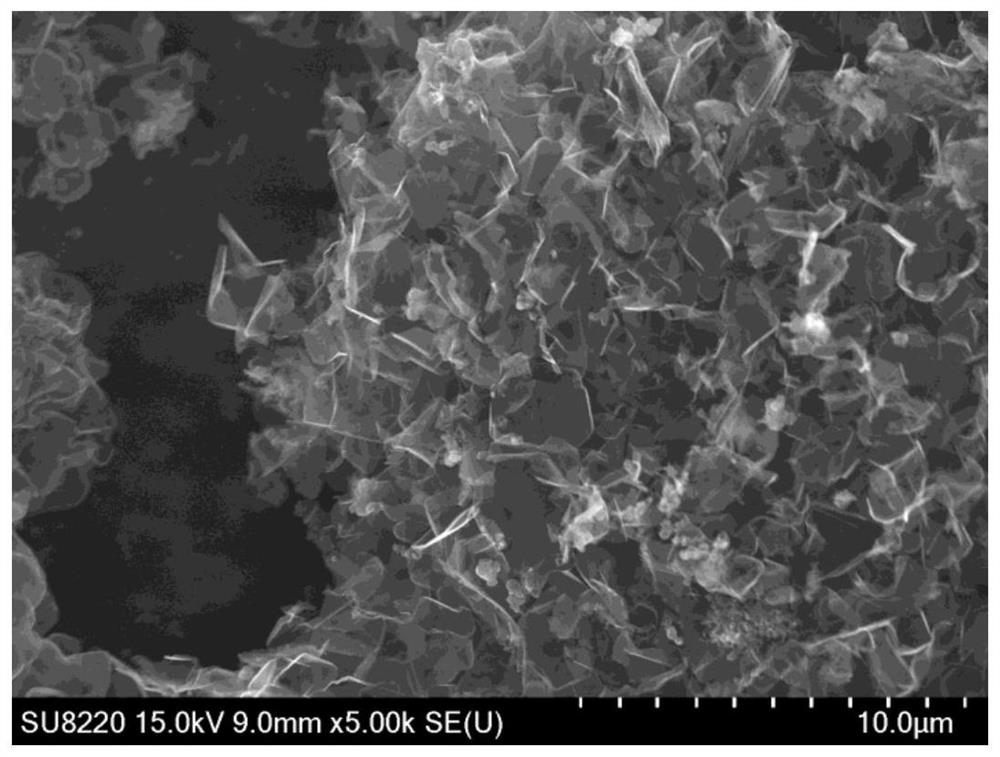

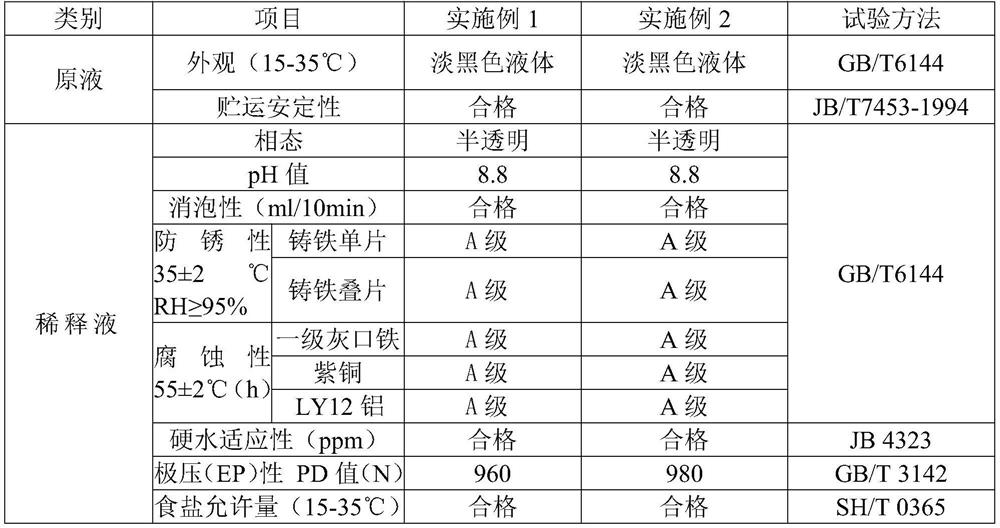

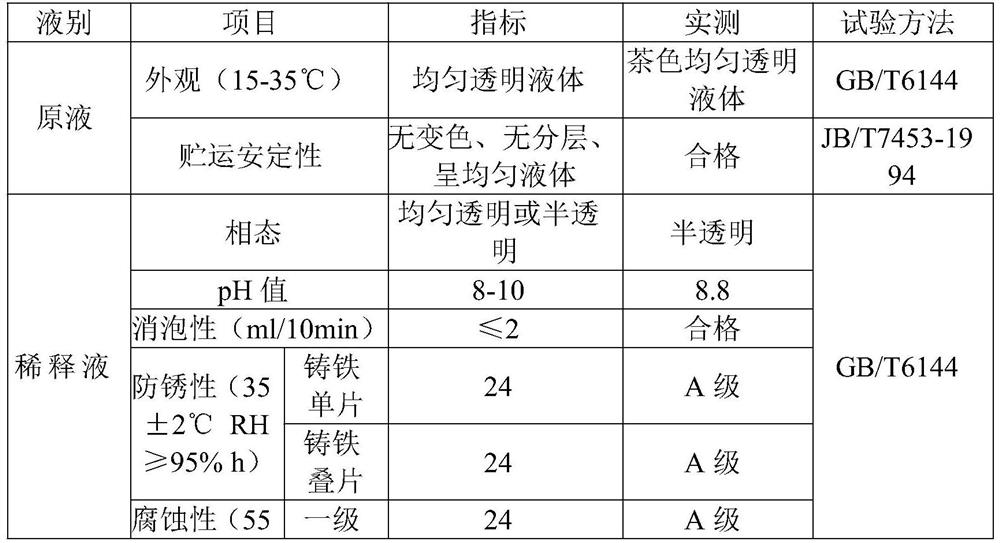

[0033] A graphene synergistic environmentally friendly water-based cutting fluid that does not need to be discharged is composed of the following components by mass percentage: 8% calcium petroleum sulfonate, 10% ammonium boride diacetate, 0.1% ethylenediaminetetraacetic acid, benzotri Nitrazole 2%, trioctyl ester 3%, emulsified silicone oil 2%, dimethyl fumarate 2%, graphene dispersion 10% and water 62.9%.

[0034] Described graphene dispersion liquid is made up of following components by mass percentage: Graphene 1%, sodium dodecylbenzene sulfonate 2% and deionized water make up to 100%; The preparation of described graphene dispersion liquid The method comprises the following steps: 5 grams of the graphene powder material prepared above and 10 grams of sodium dodecylbenzenesulfonate are dispersed in deionized water, stirred and mechanically ground for 30 minutes at 1000 rpm / min, and configured as a graphene dispersed liquid.

[0035] The preparation method of the graphene ...

Embodiment 2

[0039] A graphene synergistic environmental-friendly water-based cutting fluid that does not require discharge, and is composed of the following components by mass percentage: 10% sodium petroleum sulfonate, 8% sodium citrate, 0.1% ethylenediaminetetraethylene disodium salt, and sodium benzoate 3%, trioctyl ester 3%, emulsified silicone oil 2%, dimethyl fumarate 2%, graphene dispersion 10% and water 61.9%.

[0040] Described graphene dispersion liquid is made up of following components by mass percentage: graphene 1%, emulsifier 2% and deionized water supplement to 100%; Described emulsifier is OP-10; Described graphene The preparation method of the dispersion comprises the following steps: dispersing OP-10 in deionized water, stirring at 1000r / min for 20 minutes, configuring it into an aqueous solution, adding graphene powder, and ultrasonically treating it for 30 minutes to obtain a graphene dispersion.

[0041] The preparation method of the graphene synergistic no-discharge...

Embodiment 3

[0049] A graphene-enhanced environmental-friendly water-based cutting fluid that does not need to be discharged. It is composed of the following components by mass percentage: 10% of Swire oil, 8% of boron diacetate ammonium, 0.1% of ethylenediaminetetraacetic acid, and benzotriazole 2%, 2,6-tertiary butyl-4-methylphenol 3%, emulsified silicone oil 2%, dimethyl fumarate 2%, graphene dispersion 12% and water 60.9%.

[0050] Described graphene dispersion liquid is made up of following components by mass percentage: graphene 1%, emulsifier 2% and deionized water 97%; Described emulsifier is Triton X-100; Described graphene dispersion The preparation method of the liquid comprises the following steps: dispersing Triton X-100 in deionized water, stirring at 1000r / min for 20 minutes, configuring it into an aqueous solution, adding graphene powder, and ultrasonically treating it for 30 minutes to obtain a graphene dispersion.

[0051] The preparation method of the graphene synergisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com