Method for producing biological feed through straw fermentation

A technology of biological feed and straw, which is applied in animal feed, animal feed, application, etc., can solve the problems of difficult rapid growth, high cost, long fermentation cycle, etc., and achieve the effects of rich yield, improved hand shape, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

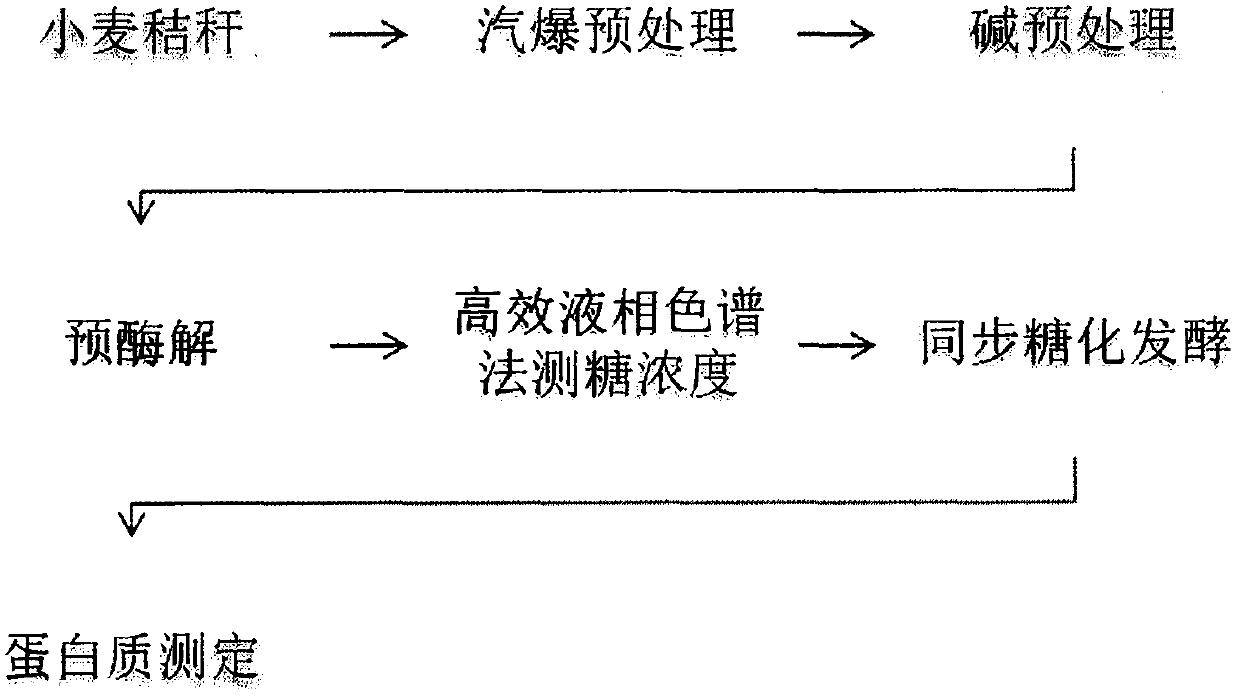

Method used

Image

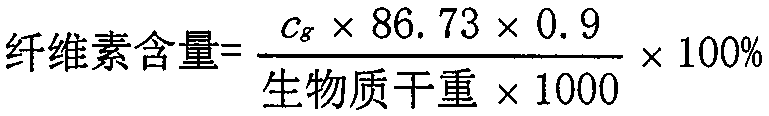

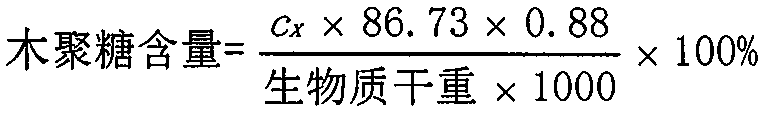

Examples

Embodiment example 1

[0027] Fermentation of untreated material

[0028] The unpretreated wheat straw is cut to 2-3 cm, pulverized by a pulverizer, and screened through 20 meshes.

[0029] (2) Pre-enzymolysis of unpretreated materials, the reaction volume is 200ml, and the addition amount of dextran is 10% (w / v). Each feeding is 3%, and the feeding time interval is 8h and 16h respectively. After the feeding is completed, the pre-enzymolysis is 12-24h. The bacterial suspensions of plant lactic acid bacteria, Bacillus subtilis, Saccharomyces cerevisiae, Candida utilis, Bacillus amyloliquefaciens, and Bacillus licheniformis were mixed and inoculated into the enzymolysis solution according to a certain ratio, and anaerobic fermentation was carried out. The reaction temperature was 30 -32°C, fermentation time 3-5 days, rotation speed 170-220r / min. Liquid feed can be obtained, solid feed can be obtained by drying and other methods, and biological feed that is beneficial to storage can be obtained by fu...

Embodiment example 2

[0031] Cut the natural air-dried wheat straw into small pieces with a length of less than 2-3 cm, add 2% NaOH solution according to the ratio of material to liquid (1:20 (g:mL), mix well, and pretreat in a high-pressure steam sterilizer at 121 ° C for 1 hours, the solid residue was washed with water until neutral, air-dried, crushed, and passed through 20 meshes.

[0032] The above-mentioned alkali pretreatment material is pre-enzymolyzed, the reaction volume is 200ml, and the dextran load is 10% (w / v). 3% feed, feeding time intervals were 8h, 16h, after feeding, pre-enzymolysis 12-24h. The bacterial suspensions of plant lactic acid bacteria, Bacillus subtilis, Saccharomyces cerevisiae, Candida utilis, Bacillus amyloliquefaciens, and Bacillus licheniformis were mixed and inoculated into the enzymolysis solution according to a certain ratio, and anaerobic fermentation was carried out. The reaction temperature was 30 -32°C, fermentation time 3-5 days, rotation speed 170-220r / mi...

Embodiment example 3

[0034] Add 2-3cm of natural air-dried straw, add 200g each time, maintain the temperature at 220°C, the pressure at 2.2MPa, and maintain the time for 5min, release the pressure instantly to make the material explode, collect the blasted material, wash the solid residue until neutral, and air dry After crushing, pass through 20 mesh.

[0035]The above-mentioned alkali pretreatment material is pre-enzymolyzed, the reaction volume is 200ml, and the dextran load is 10% (w / v). 3% feed, feeding time intervals were 8h, 16h, after feeding, pre-enzymolysis 12-24h. The bacterial suspensions of plant lactic acid bacteria, Bacillus subtilis, Saccharomyces cerevisiae, Candida utilis, Bacillus amyloliquefaciens, and Bacillus licheniformis were mixed and inoculated into the enzymolysis solution according to a certain ratio, and anaerobic fermentation was carried out. The reaction temperature was 30 -32°C, fermentation time 3-5 days, rotation speed 170-220r / min. Liquid feed can be obtained,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com