Continuous salt production method and system

A nanofiltration and concentrated water technology, applied in the purification of alkali metal sulfite/sulfate, calcium/strontium/barium sulfate, alkali metal halide purification, etc., can solve the problem of high investment and energy consumption, chromaticity of crystal salt and purity effects, to achieve the effects of reducing operating costs, improving heat utilization efficiency, and improving recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

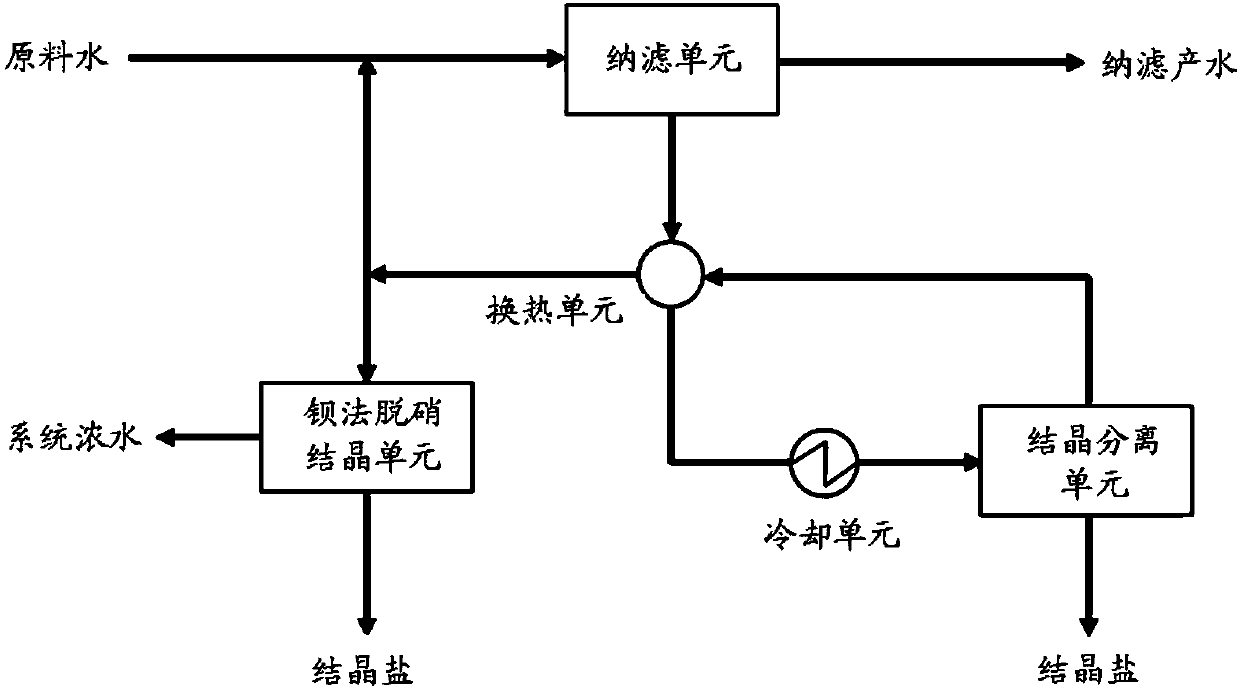

[0078] combine figure 1 , This embodiment is used to illustrate the continuous salt production method of the present invention.

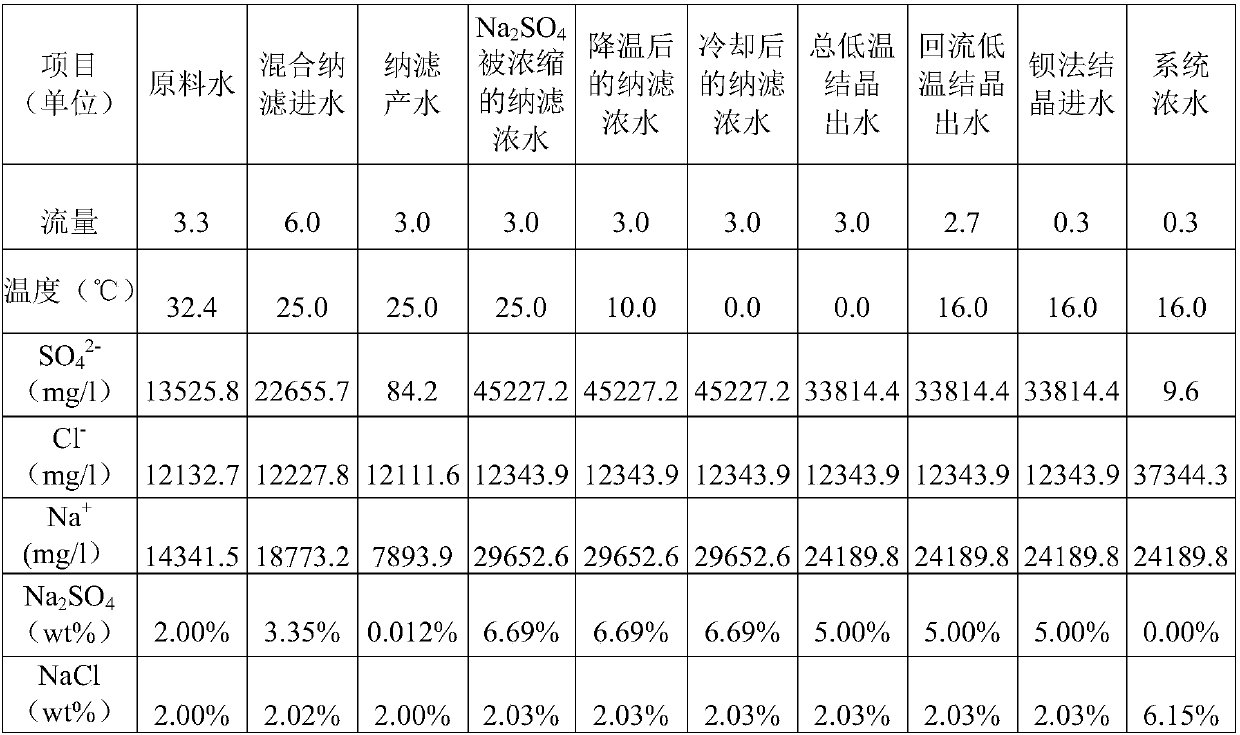

[0079] In this example, the nanofiltration unit is a one-stage one-stage nanofiltration system composed of six GE SWSR-400 nanofiltration membrane elements connected in series, and the crystallization separation unit includes a 1.5m 3 The stainless steel container and centrifugal separation device, the barium denitrification crystallization unit includes a volume of 0.3m 3 Stainless steel container and centrifugal separation device, the feed water flow rate of raw water is 3.3m 3 / h, the specific process is as follows:

[0080] (1) Set the flow rate to 3.3m 3 / h, the temperature is the synthetic brine shown in Table 1 of 32.4 ℃ as raw material water and the flow rate from step (5) is 2.7m 3 / h, the reflux low temperature crystallization effluent at 16°C is mixed, and the mixed nanofiltration influent is obtained and 6.0m 3 The total flow rate p...

Embodiment 2

[0093] This embodiment is used to illustrate the continuous salt production method of the present invention.

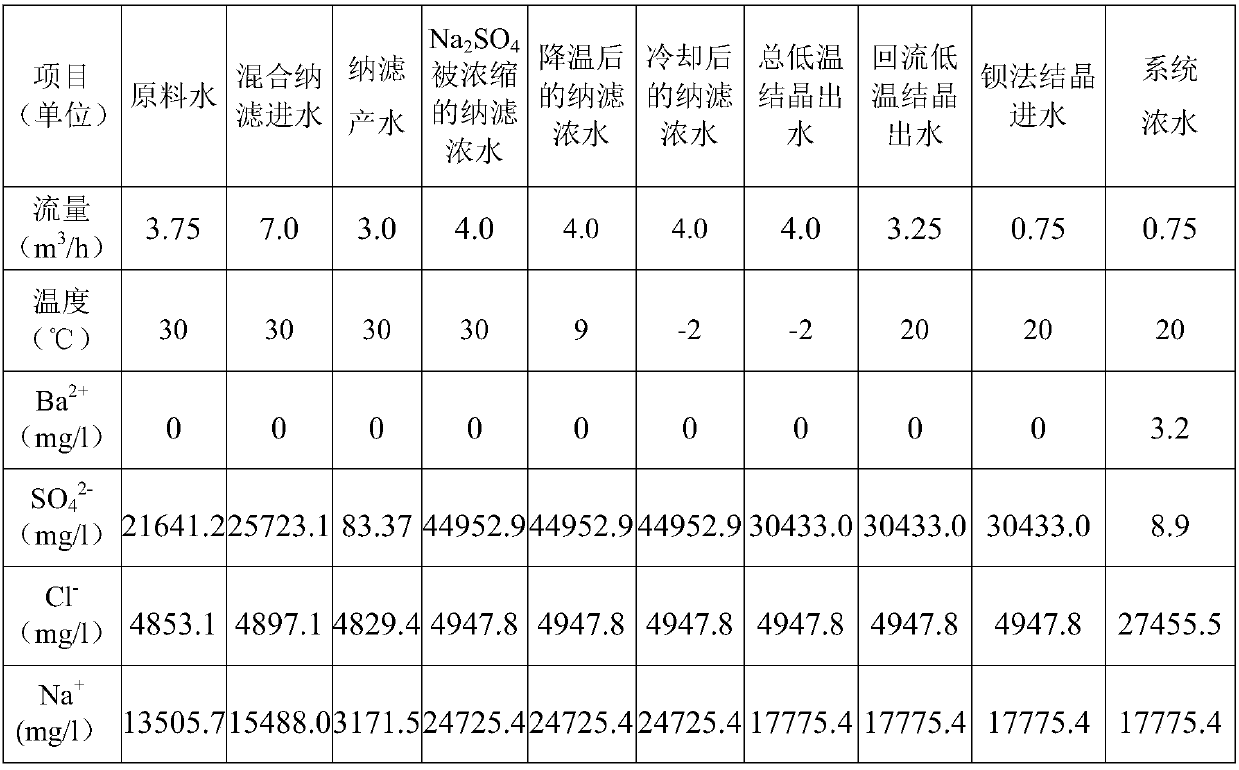

[0094] In this example, the nanofiltration unit is a one-stage one-stage nanofiltration system composed of six GE SWSR-400 nanofiltration membrane elements connected in series, and the crystallization separation unit includes a 2.0m 3 The stainless steel container and centrifugal separation device, the barium denitrification crystallization unit includes a volume of 0.7m 3 Stainless steel container and centrifugal separation device, the feed water flow rate of raw water is 3.75m 3 / h, the specific process is as follows:

[0095] (1) Set the flow rate to 3.75m 3 / h, temperature is the synthetic brine shown in table 2 of 30 ℃ as raw material water and the flow that obtains from step (6) is 3.25m 3 / h, heated up to 30°C and mixed with refluxed low-temperature crystallization effluent to obtain mixed nanofiltration influent and 7.0m 3 The total flow rate per hour and ...

Embodiment 3

[0110] This embodiment is used to illustrate the continuous salt production method of the present invention.

[0111] In this example, the nanofiltration unit is a one-stage one-stage nanofiltration system composed of six GE DSL NF8040 nanofiltration membrane elements in series, and the crystallization separation unit includes a 0.75m 3 The stainless steel container and centrifugal separation device, the barium denitrification crystallization unit includes a volume of 0.15m 3 Stainless steel container and centrifugal separation device, the inflow flow rate of raw water is 3.125m 3 / h, the specific process is as follows:

[0112] (1) Set the flow rate to 3.125m 3 / h, temperature is the synthetic brine shown in Table 3 of 18.1 ℃ as raw material water and the flow rate from step (5) is 1.375m 3 / h, the reflux low temperature crystallization effluent at a temperature of 8°C is mixed, and the mixed nanofiltration influent is obtained and 4.5m 3 The total flow rate per hour and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com