Preparation method of senkyunolide I

A technology for yangchuanxiong lactone and ligustilide, which is applied in the field of preparation of yangchuanxiong lactone I, can solve the problems of limited sources, limited in-depth research, new drug development, complicated process and the like, and achieves the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of ligustilide I, the steps of which are:

[0028] (1) Preparation of Rhizoma Chuanxiong Extract: 1 kg of Rhizoma Chuanxiong, crushed, extracted twice with 8 times the amount of 80% ethanol under reflux, combined the extracts, evaporated the solvent under reduced pressure at 45°C, dispersed the obtained extract with ethyl acetate Ester extraction, combining the organic layers, and distilling off the solvent under reduced pressure at 45°C to obtain 56.4 g of oily extract, i.e. Chuanxiong extract;

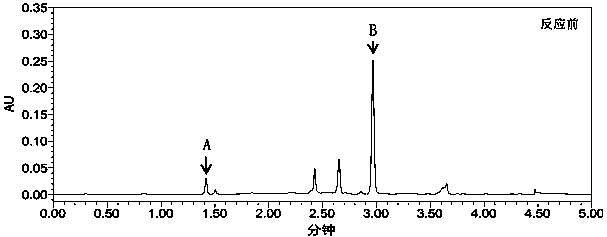

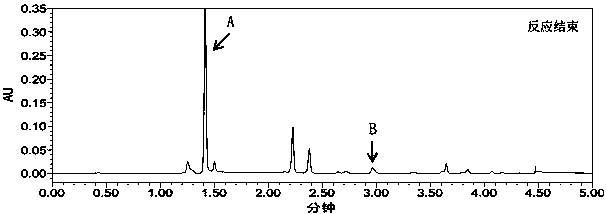

[0029] (2) Reaction: 300 ml of water-ethanol mixed solution (50:50, v / v), 15 g of Chuanxiong extract prepared in step (1) (ligustilide content 19.5%, w / w; Chuanxiong lactone I 0.8%, w / w) was added to a 500 ml round bottom flask in sequence, and stirred for 5 minutes at room temperature; 30 g of potassium hydrogen persulfate compound salt and 12 g of sodium bicarbonate were finely ground and mixed, and slowly added to the reaction system , stirred at room ...

Embodiment 2

[0037] A preparation method of ligustilide I, the steps of which are:

[0038] (1) Preparation of angelica extract: 5 kg of angelica medicinal materials were crushed, passed through a No. 3 sieve, and extracted by steam distillation to obtain 27.8 g of volatile oil;

[0039] (2) Reaction: 200 ml of water-1,4-dioxane (50:50, v / v), 10 g of Angelica volatile oil prepared in step (1) (55.1% ligustilide content, w / w; Ligustilide I 3.2%, w / w) was added to a 500 ml round bottom flask in turn, and stirred at room temperature for 10 minutes. Take 45 g of potassium hydrogen persulfate compound salt and 16 g of sodium bicarbonate, grind and mix well, slowly add to the reaction system, stir at room temperature for 30 minutes, then raise the temperature to 100°C for 6 hours;

[0040] (3) Separation: After the reaction, remove the insoluble matter by filtration, concentrate the filtrate under reduced pressure at 50°C to remove 1,4-dioxane, and then extract with ethyl acetate (100 ml×3 tim...

Embodiment 3

[0043] A preparation method of ligustilide I, the steps of which are:

[0044] (1) Preparation of Ligusticum edulis extract: 2 kg of Ligusticum edulis medicinal materials were crushed, passed through a No. 3 sieve, and extracted by steam distillation to obtain 14.3 g of Ligusticum volatile oil;

[0045] (2) Reaction: Mix 200 ml of water-butanone (40:60, v / v), 10 g of Ligusticum volatile oil obtained in step (1) (ligustilide content 28.2%, w / w; Lactone I 1.4%, w / w) were successively added to a 500 ml round bottom flask and stirred at room temperature for 5 minutes. Take 30 g of potassium hydrogen persulfate compound salt and 12 g of sodium acetate, grind and mix well, slowly add to the reaction system, stir at room temperature for 30 minutes, then raise the temperature to 60°C for 12 hours;

[0046] (3) Separation: After the reaction, remove the insoluble matter by filtration, concentrate the filtrate under reduced pressure at 50°C to remove butanone, and then extract with eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com