Novel natural bacteriostatic fiber spunlace material and preparation method and application thereof

A new material and fiber technology, applied in the field of natural antibacterial fiber spunlace new material and its preparation, can solve the problems of inability to provide a sterile environment, no antibacterial properties, and less functionality of the finished product, and achieve improved quality and reliability. Spinning, retaining bacteriostatic effect, improving moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

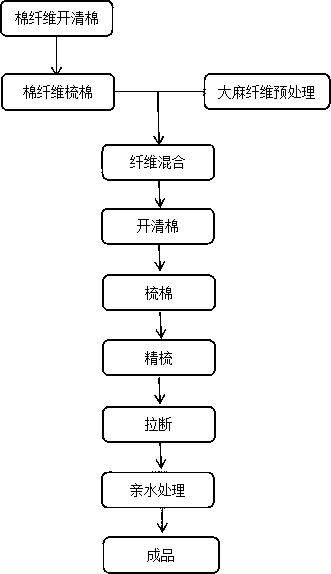

Method used

Image

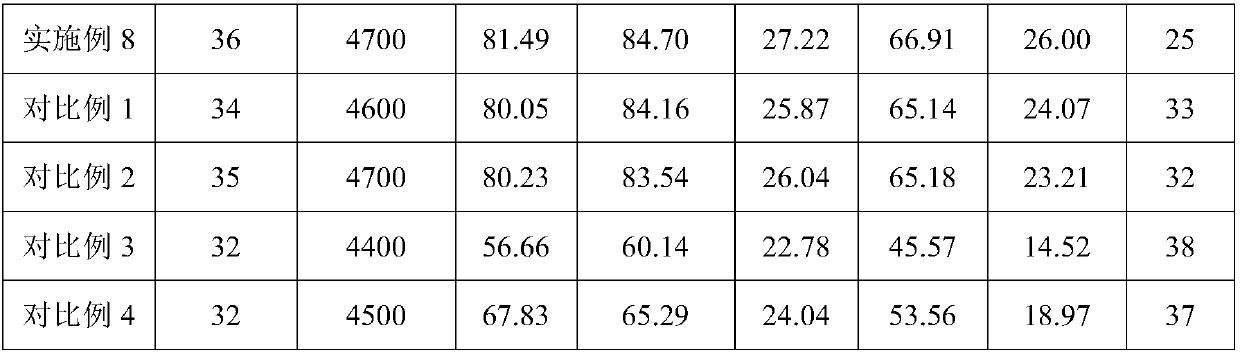

Examples

Embodiment 1

[0044]The pretreatment method of embodiment 1 hemp fiber

[0045] Choose Heilongjiang hemp fiber, length after processing is 33mm, pretreatment solution is sprayed on the hemp fiber, wherein the mass ratio of pretreatment solution and hemp fiber is 5:100;

[0046] Described pretreatment solution is made up of compound oil agent and water, and the ratio of compound oil agent and water is 1:6;

[0047] The compound oil agent is composed of antistatic agent, softening agent and penetrating agent with a mass ratio of 2:1:1, wherein the antistatic agent is FD-ZY06B, the softening agent is FD-ZY06A, and the penetrating agent is a prophylaxis for fiber treatment. Water-based penetrant.

Embodiment 2

[0048] The pretreatment method of embodiment 2 hemp fibers

[0049] Choose Heilongjiang hemp fiber, the length after processing is 38mm, the pretreatment solution is sprayed on the hemp fiber, and wherein the mass ratio of pretreatment solution and hemp fiber is 1:80;

[0050] Described pretreatment solution is made up of compound oil agent and water, and the ratio of compound oil agent and water is 1:4;

[0051] The compound oil is composed of antistatic agent, softening agent and penetrating agent with a mass ratio of 2:1:0.5, wherein the antistatic agent is FD-ZY06B, the softening agent is FD-ZY06A, and the penetrating agent is a prophylaxis for fiber treatment. Water-based penetrant.

Embodiment 3

[0052] The pretreatment method of embodiment 3 hemp fibers

[0053] Choose Heilongjiang hemp fiber, length after processing is 36mm, pretreatment solution is sprayed on the hemp fiber, wherein the mass ratio of pretreatment solution and hemp fiber is 4:90;

[0054] Described pretreatment solution is made up of compound oil agent and water, and the ratio of compound oil agent and water is 1:8;

[0055] The compound oil is composed of antistatic agent, softening agent and penetrating agent with a mass ratio of 2:1:0.8, wherein the antistatic agent is FD-ZY06B, the softening agent is FD-ZY06A, and the penetrating agent is a prophylaxis for fiber treatment. Water-based penetrant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com