Chicken sternal cartilage powder and preparation method and application thereof

A technology of cartilage powder and chicken breast, which is applied in bone diseases, powder delivery, and pharmaceutical formulations, etc., can solve the problems that ordinary consumers cannot bear, the purification process is complicated, and the price is expensive. cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

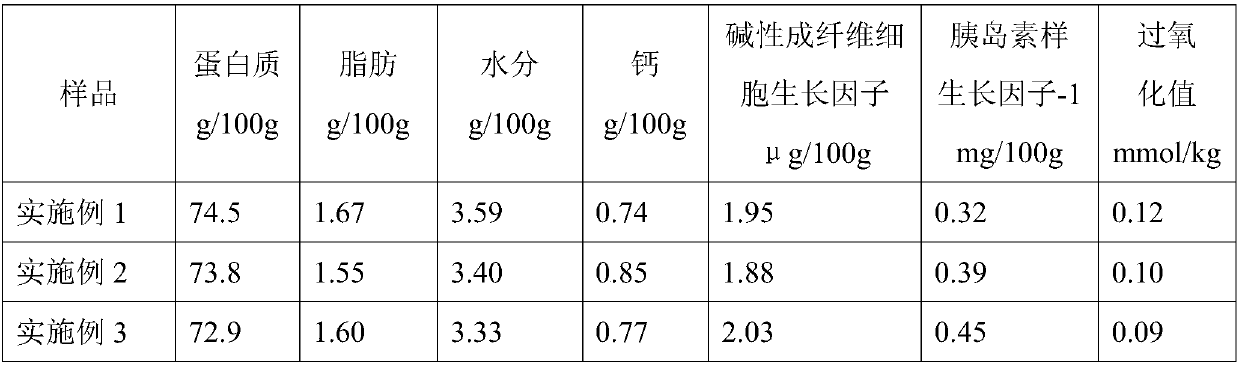

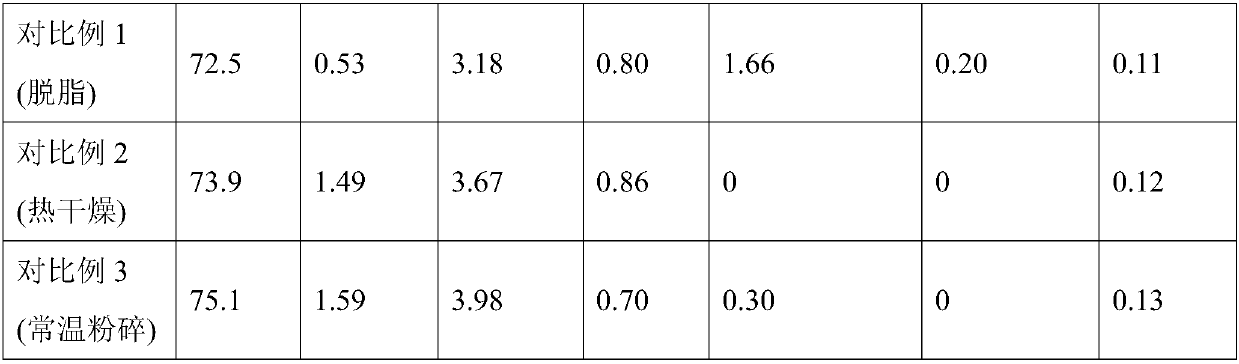

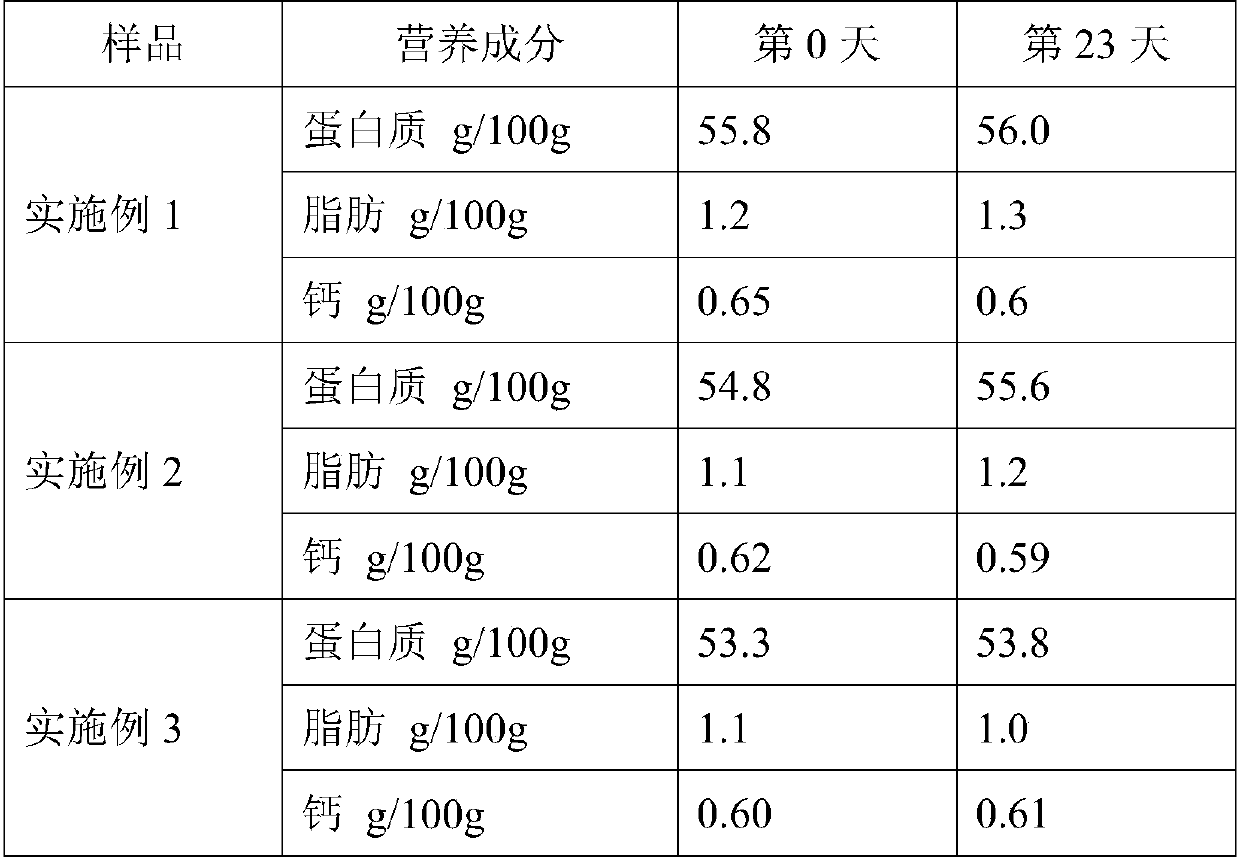

Examples

Embodiment 1

[0059] A kind of chicken breast cartilage powder, its preparation method comprises the following steps:

[0060] 1) Take fresh chicken breast cartilage, remove chicken, skin, periosteum and other non-cartilage substances, wash it with pure water, and cut it into thin slices with a size of about 2mm×3mm×0.5mm;

[0061] 2) Freeze chicken breast cartilage thin slices at -60°C to -80°C for 12-24 hours (subject to freezing), then freeze-dry at -50°C until the water content is lower than 3%; Under the condition of 50°C, perform low-temperature ultrafine pulverization until the particle size is 100-150 mesh to obtain chicken breast cartilage powder.

Embodiment 2

[0063] A kind of chicken breast cartilage powder, its preparation method comprises the following steps:

[0064] 1) Take fresh chicken breast cartilage, remove chicken, skin, periosteum and other non-cartilage substances, wash it with pure water, and cut it into thin slices with a size of about 2mm×3mm×0.5mm;

[0065] 2) Freeze chicken breast cartilage thin slices at -80°C to -100°C for 12-15 hours (subject to freezing), then freeze-dry at -55°C until the water content is lower than 3%; Under the condition of 50°C, perform low-temperature ultrafine pulverization until the particle size is 100-150 mesh to obtain chicken breast cartilage powder.

Embodiment 3

[0067] A kind of chicken breast cartilage powder, its preparation method comprises the following steps:

[0068] 1) Take fresh chicken breast cartilage, remove chicken, skin, periosteum and other non-cartilage substances, wash it with pure water, and cut it into thin slices with a size of about 2mm×3mm×0.5mm;

[0069] 2) Freeze chicken breast cartilage thin slices at -150°C to -196°C for at least 12 hours (subject to freezing), then freeze-dry at -60°C until the water content is lower than 3%; Under the condition of ℃, carry out low-temperature ultrafine pulverization, and pulverize to a particle fineness of 100-150 mesh to obtain chicken breast cartilage powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com