Nickel-doped manganese ferrite coated magnesium silicate composite catalyst and preparation method and application thereof

A technology of composite catalyst and manganese ferrite, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of ineffective removal of basic fuchsin, achieve rapid and complete degradation in a short time, Fast speed, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Ni-MnFe 2 o 4 @M-S-H Catalyst

[0017] (1) Preparation method

[0018] 1. Nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ) preparation: 3.636g Fe(NO 3 ) 3 9H 2 O and 0.1428g Ni(NO 3 ) 3 ·6H 2 O and 0.5mL 50%Mn(NO 3 ) 2 Mix and dissolve in 30ml ultrapure water, adjust the pH to 12.0 with NaOH, and stir evenly to obtain nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ). molar ratio Fe 3+ :Mn 2+ =2:1, by weight percentage, Ni content is 0.9%.

[0019] 2. Preparation of magnesium silicate (M-S-H): Mix 2.0mol / L magnesium nitrate aqueous solution and 3.0mol / L sodium silicate aqueous solution to form a precipitate, wash the precipitate with ultrapure water until neutral, filter, dry, and grind to obtain Magnesium silicate powder.

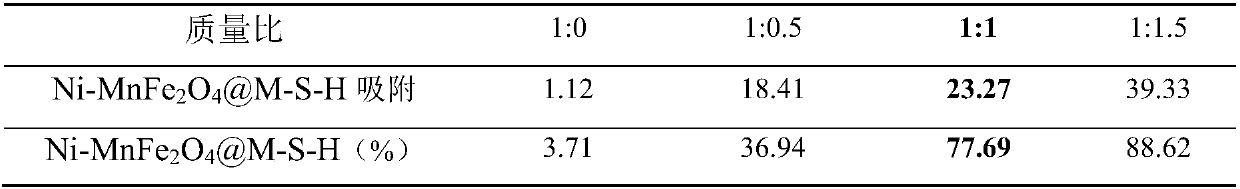

[0020] 3. According to the mass ratio, Ni-MnFe 2 o 4 : M-S-H=(1.0:0)-(1.0:1.5), take nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ) and magnesium silicate, after mixing, the mixture is transferred to a polytetrafluoroet...

Embodiment 2

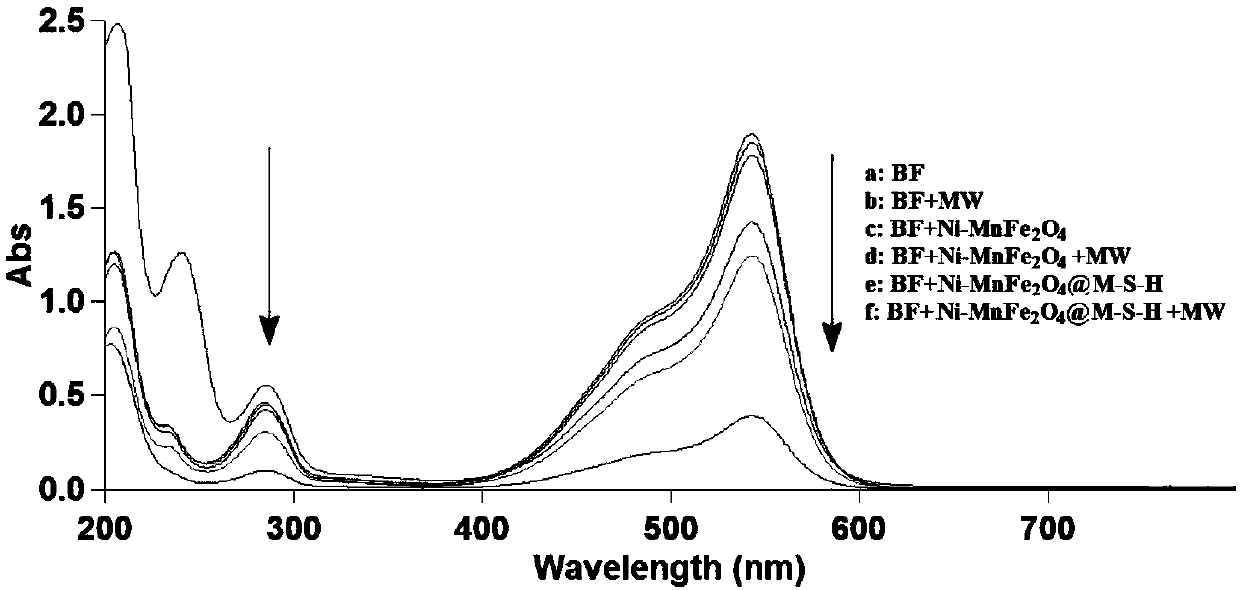

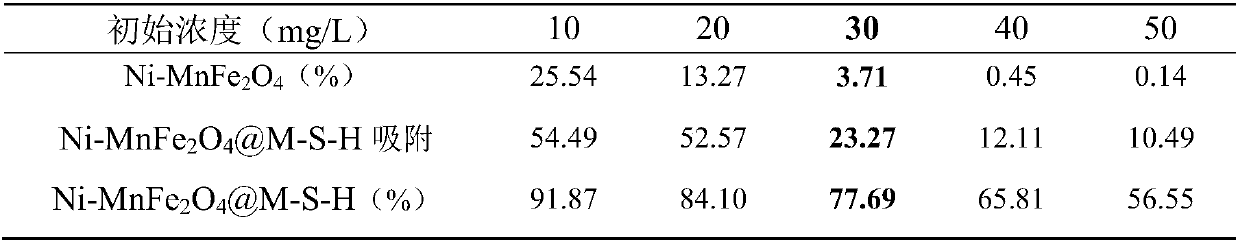

[0028] Example 2 Degradation of organic pollutants basic fuchsin

[0029] (1) Preparation method

[0030] 1. Nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ) preparation: 3.636g Fe(NO 3 ) 3 9H 2 O and 0.1428g Ni(NO 3 ) 3 ·6H 2 O and 0.5mL 50% Mn(NO 3 ) 2 Mix and dissolve in 30ml ultrapure water, adjust the pH to 12.0 with NaOH, and stir evenly to obtain nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ). molar ratio Fe 3+ :Mn 2+=2:1, by weight percentage, Ni content is 0.9%.

[0031] 2. Preparation of magnesium silicate (M-S-H): Mix 2.0mol / L magnesium nitrate aqueous solution and 3.0mol / L sodium silicate aqueous solution to form a precipitate, wash the precipitate with ultrapure water until neutral, filter, dry, and grind to obtain Magnesium silicate powder.

[0032] 3. According to the mass ratio, Ni-MnFe 2 o 4 : M-S-H=1.0:1.0, take nickel-doped manganese ferrite (Ni-MnFe 2 o 4 ) and magnesium silicate, after mixing, the mixture is transferred to a polytetrafl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com