Bio-carbon fertilizer as well as preparation method and application thereof

A technology of biochar and monoammonium phosphate, applied in the field of agriculture, can solve the problems of waste of resources, environment, pollution, etc., and achieve the effect of solving pollution treatment, promoting crop growth, and improving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also relates to the preparation method of biochar fertilizer as described above, comprising:

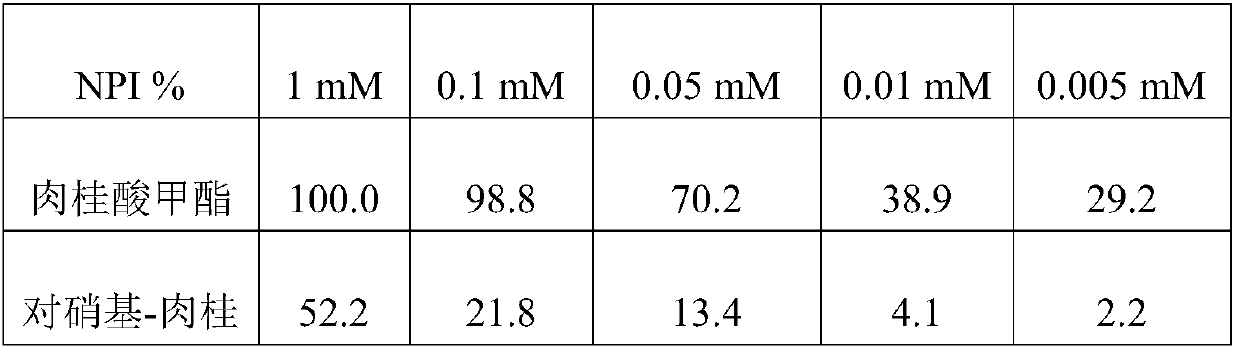

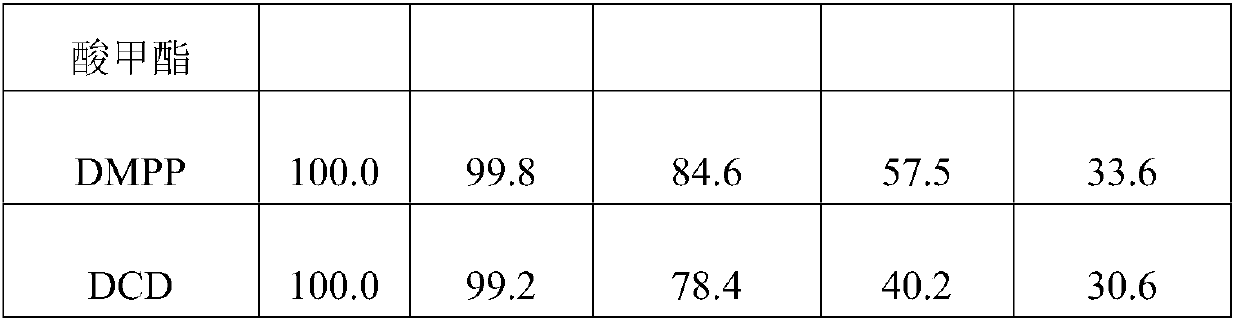

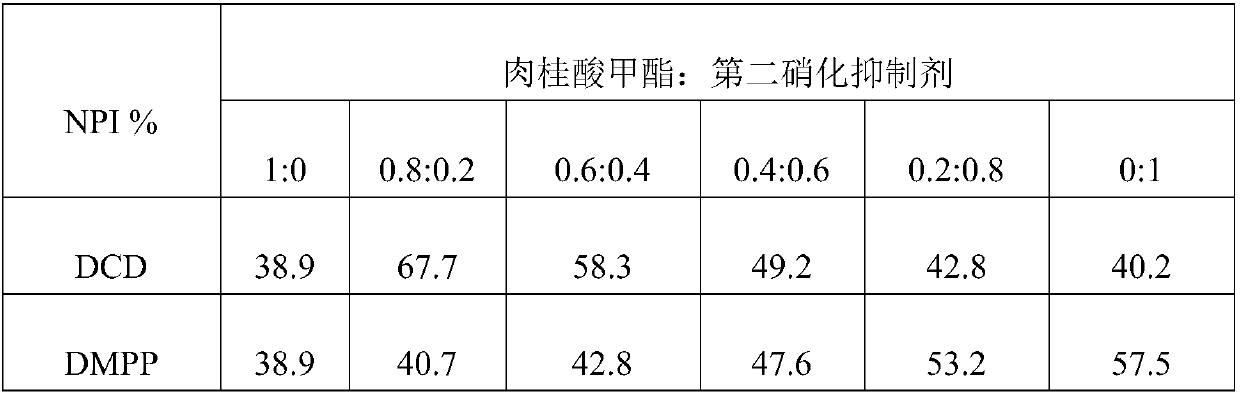

[0038] The biochar, attapulgite, sepiolite, dried poultry manure, monoammonium phosphate, calcium magnesium phosphate fertilizer, potassium chloride, urea, methyl cinnamate and dicyandiamide are mixed and granulated to obtain the product.

[0039] According to one aspect of the present invention, the present invention also relates to the application of the above-mentioned biochar fertilizer as a long-acting corn fertilizer.

Embodiment 1

[0042] The present embodiment provides a kind of biochar fertilizer, comprising:

[0043] 50g of biochar, 10g of attapulgite, 50g of sepiolite, 20g of dried poultry manure (cow manure accounts for 60wt%, chicken manure accounts for 40wt%), 5g of monoammonium phosphate, 14g of calcium magnesium phosphate fertilizer, 14g of potassium chloride, and 8g of urea , methyl cinnamate 1.6g and dicyandiamide 0.2g;

[0044] Wherein, the particle diameters of the attapulgite and the sepiolite are both 200 mesh;

[0045] The preparation method of the biochar is as follows: collecting the black liquor of wheat straw pulping by the immonium method of a paper mill, and drying at 80° C. for 24 hours to remove moisture. The dry lignin powder was placed in a cylindrical stainless steel reactor with a lid of 14.5 cm height and 7.5 cm inner diameter, and pyrolyzed in a muffle furnace (2116, Thermo Scientific, America) at 600 °C for 1.5 h. The reactor was then cooled to room temperature in the fur...

Embodiment 2

[0048] The present embodiment provides a kind of biochar fertilizer, comprising:

[0049]70g of biochar, 30g of attapulgite, 30g of sepiolite, 40g of dried poultry manure (cow manure accounts for 70wt%, chicken manure accounts for 30wt%), monoammonium phosphate 3g, calcium magnesium phosphate fertilizer 20g, potassium chloride 6g, urea 12g , methyl cinnamate 2.4g and dicyandiamide 0.3g;

[0050] Wherein, the particle diameters of the attapulgite and the sepiolite are both 160 mesh;

[0051] The preparation method of the biochar is as follows: collecting the black liquor of wheat straw pulping by the immonium method of a paper mill, and drying at 80° C. for 24 hours to remove moisture. The dry lignin powder was placed in a cylindrical stainless steel reactor with a lid of 14.5 cm height and 7.5 cm inner diameter, and pyrolyzed in a muffle furnace (2116, Thermo Scientific, America) at 400 °C for 2.5 h. The reactor was then cooled to room temperature in the furnace.

[0052] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com