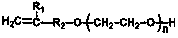

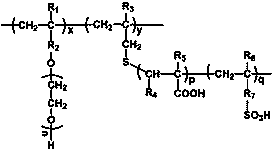

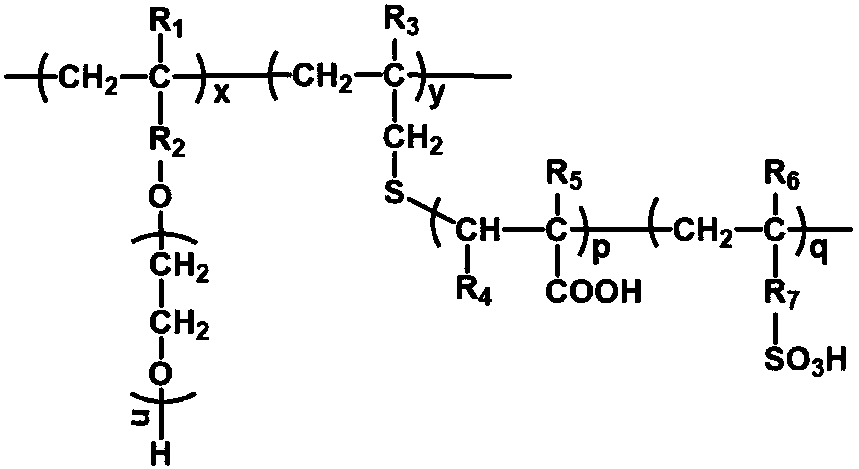

Double-side chain polycarboxylate superplasticizer and preparation method thereof

A technology of chain polycarboxylate and water reducer, which is applied in the field of double side chain polycarboxylate water reducer and its preparation, can solve problems such as insufficient water reducing rate, poor adaptability of cement materials, excessive viscosity of high-strength concrete, etc., and achieve Good tolerance, low cost, high water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of prepolymer

[0050] In the reactor equipped with thermometer and stirrer, add allyl chloride 25.5g, HPEG (M w =2000) 2000g, 2-mercaptoethanol 5.08g and AIBN 20.3g, after mixing evenly, raise the temperature to 120°C and react for 6h to prepare the corresponding prepolymer.

[0051] (2) Thiolation

[0052] The temperature of the above system was maintained at 120°C, 19.6 g of sodium hydrosulfide was added, and the reaction was stirred for 6 hours to prepare the corresponding macromolecular chain transfer agent containing mercapto groups.

[0053] (3) Introducing adsorption side chains

[0054] Lower the temperature of the above system to 60°C, add 120g of acrylic acid, 48.1g of sodium allyl sulfonate, 0.85g of potassium persulfate and 2200g of water, stir and react for 3 hours, then add a certain amount of NaOH solution and water to adjust the solid content to 30% , and the pH value is 7.0, the corresponding double side chain polycarboxylate superpl...

Embodiment 2

[0057] (1) Preparation of prepolymer

[0058] In the reactor equipped with thermometer and stirrer, add allyl chloride 19.1g, IPEG (M w =2400) 2400g, 4.84g of 2-mercaptoacetic acid and 21.8g of BPO, after mixing evenly, the temperature was raised to 120°C, and the corresponding prepolymer was prepared after reacting for 6 hours.

[0059] (2) Thiolation

[0060] The temperature of the above system was maintained at 120°C, 15.4 g of sodium hydrosulfide was added, and the reaction was stirred for 8 hours to prepare the corresponding macromolecular chain transfer agent containing mercapto groups.

[0061] (3) Introducing adsorption side chains

[0062] Lower the temperature of the above system to 40°C, add 322.8g of methacrylic acid, 39.5g of sodium methallylsulfonate, 1.08g of VA-044 and 4200g of water, stir and react for 3 hours, then add a certain amount of NaOH solution and water to adjust The corresponding double side chain polycarboxylate water reducer can be prepared whe...

Embodiment 3

[0065] (1) Preparation of prepolymer

[0066] In the reactor equipped with thermometer and stirrer, add allyl chloride 17g, HPEG (M w =2400) 2400g, 5.32g of 3-mercaptopropionic acid and 18.1g of tert-butyl hydroperoxide, after mixing uniformly, the temperature was raised to 110°C, and the corresponding prepolymer was prepared after reacting for 4 hours.

[0067] (2) Thiolation

[0068] The temperature of the above system was maintained at 110°C, 13.7 g of sodium hydrosulfide was added, and the reaction was stirred for 8 hours to prepare the corresponding macromolecular chain transfer agent containing mercapto groups.

[0069] (3) Introducing adsorption side chains

[0070] Lower the temperature of the above system to 80°C, add 160g of acrylic acid, 217.8g of maleic anhydride, 91.6g of sodium styrene sulfonate, 1.88g of ammonium persulfate and 1950g of water, stir and react for 2 hours, then add a certain amount of NaOH solution and water to adjust The corresponding double s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com