Low-grade attapulgite raw ore heavy metal curing material and method for carrying out in-situ remediation on contaminated soil by using same

A technology of attapulgite and solidified materials, applied in the restoration of polluted soil, etc., can solve the problems of not being able to meet the market demand for remediation of heavy metal-contaminated soil, difficult to realize industrial application, and increase material costs, so as to improve adsorption performance, Strong ion exchange capacity and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

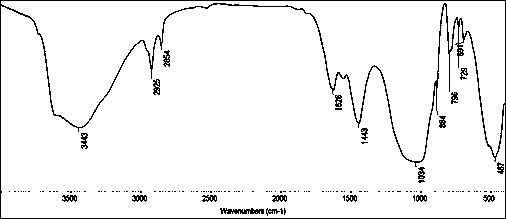

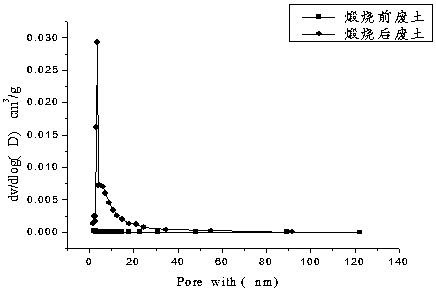

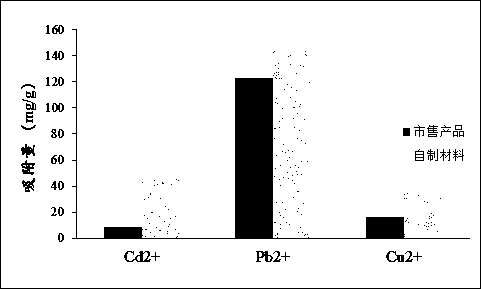

[0027] Example 1: Evenly spray the low-grade attapulgite ore with a 1% compound acid solution (the mass ratio of citric acid: sulfuric acid is 1:3), which is twice the mass of the original ore, and let it air dry for more than 3 months. Pass through a 200-mesh sieve; mix acidified attapulgite and gutter oil at a mass ratio of 10:1, press filter and send it to a rotary kiln, and carbonize at 400°C for 2 hours under a nitrogen atmosphere; dry and sieve to obtain low-grade attapulgite Rod stone raw ore heavy metal solidified material, the mass moisture of the product is controlled below 10%.

[0028] Apply the heavy metal solidification material obtained in Example 1 to rice soil (contains 432 mg / kg Pb and 1.2 mg / kg Cd after testing), mix thoroughly and evenly, and apply 450 kg / mu of soil, and leave it for 3 days without disturbance. After testing, the contents of Pb and Cd in the leachate of solidified polluted soil were 43 mg / kg (limit value 80 mg / kg) and not detected (limit va...

Embodiment 2

[0029] Example 2: Evenly spray low-grade attapulgite with a mass concentration of 2% compound acid solution (wherein the mass ratio of oleic acid: sulfuric acid is 1:4), air-dry for more than 3 months, naturally air-dry, and pulverize 200-mesh sieve; acidified attapulgite and waste engine oil are mixed at a mass ratio of 8:1, filtered and sent to a rotary kiln, and carbonized at 400°C for 2 hours in a nitrogen atmosphere; dried and sieved to obtain low-grade asphalt Rod stone raw ore heavy metal solidified material, the mass moisture of the product is controlled below 10%.

[0030] The heavy metal solidified material obtained in Example 2 is applied to the field soil (containing Pb326mg / kg, Cd2.0mg / kg, As 283mg / kg after testing), fully mixed, and the amount of application is 500kg / mu of soil. The water volume is 20%, and 15 square meters per mu is irrigated, and then left without disturbance for 4 days. After testing the heavy metal-contaminated soil, the contents of Pb, Cd, ...

Embodiment 3

[0031] Example 3: Evenly spray the low-grade attapulgite with a mass concentration of 3% compound acid solution (wherein the mass ratio of acetic acid: sulfuric acid is 1:5) to the low-grade attapulgite, air-dry for more than 3 months, naturally air-dry, and pulverize over 200 Mesh sieve; acidified attapulgite and waste tallow fat are mixed at a mass ratio of 5:1, filtered and sent to a rotary kiln, and carbonized at 500°C for 3 hours under a nitrogen atmosphere; dried and sieved to obtain low-grade uneven Rod stone raw ore heavy metal solidified material, the mass moisture of the product is controlled below 10%.

[0032] The heavy metal solidified material obtained in Example 3 is applied to the polluted soil for planting medicinal materials (containing Pb331mg / kg, Cd1.6mg / kg, As340mg / kg after testing), fully mixed, and the amount of application is 500kg / mu of soil. The water content is 18%, and 10 square meters per mu is irrigated, and then left without disturbance for 7 day...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com