Method and system for removing volatile organic compounds (VOCs) by ozone microwave excitation of magnetically separable catalyst

A magnetic separation and catalyst technology, applied in the field of flue gas purification, can solve the problems of hindering the transmission of ultraviolet light, complex systems and processes, high power consumption and operating costs, and achieve broad market development and application prospects, mature and reliable equipment, and low operating costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

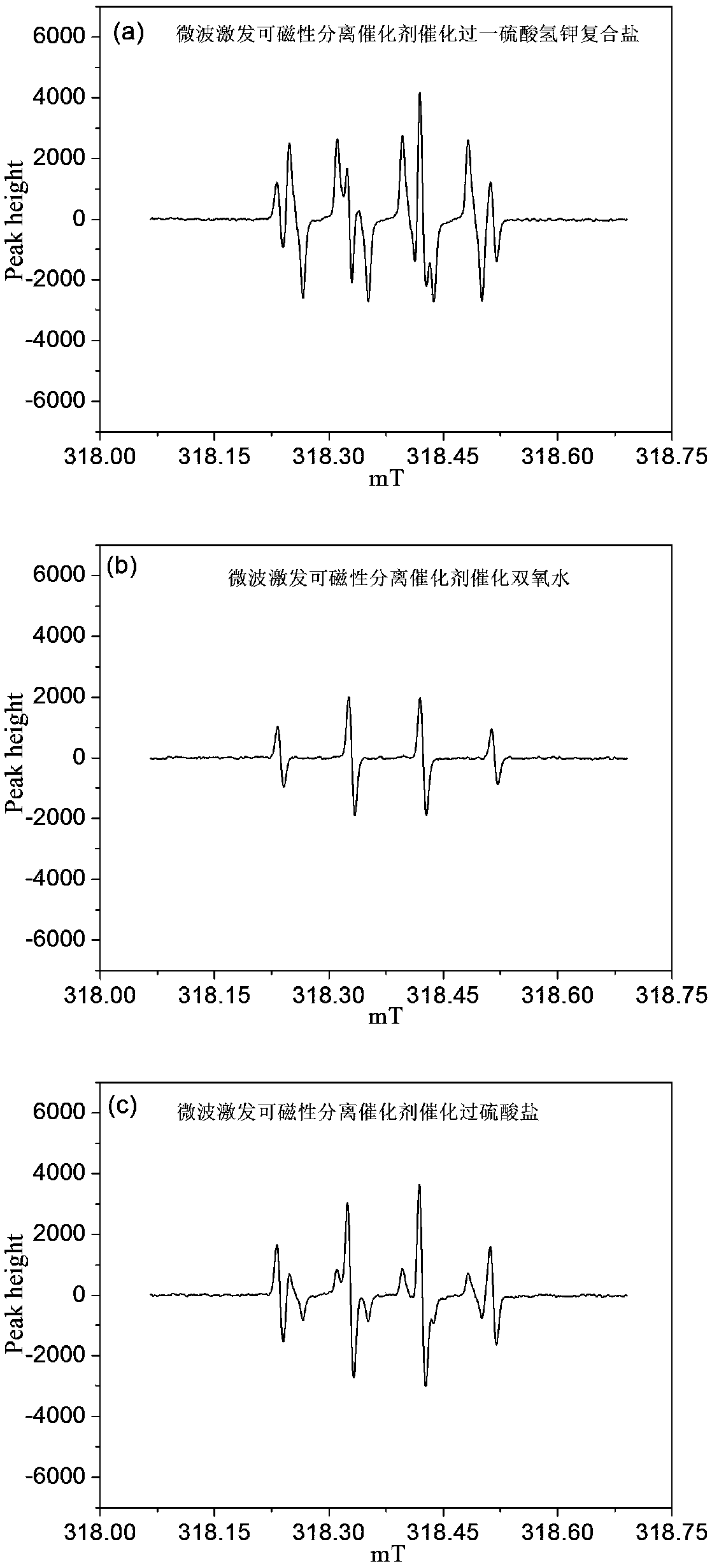

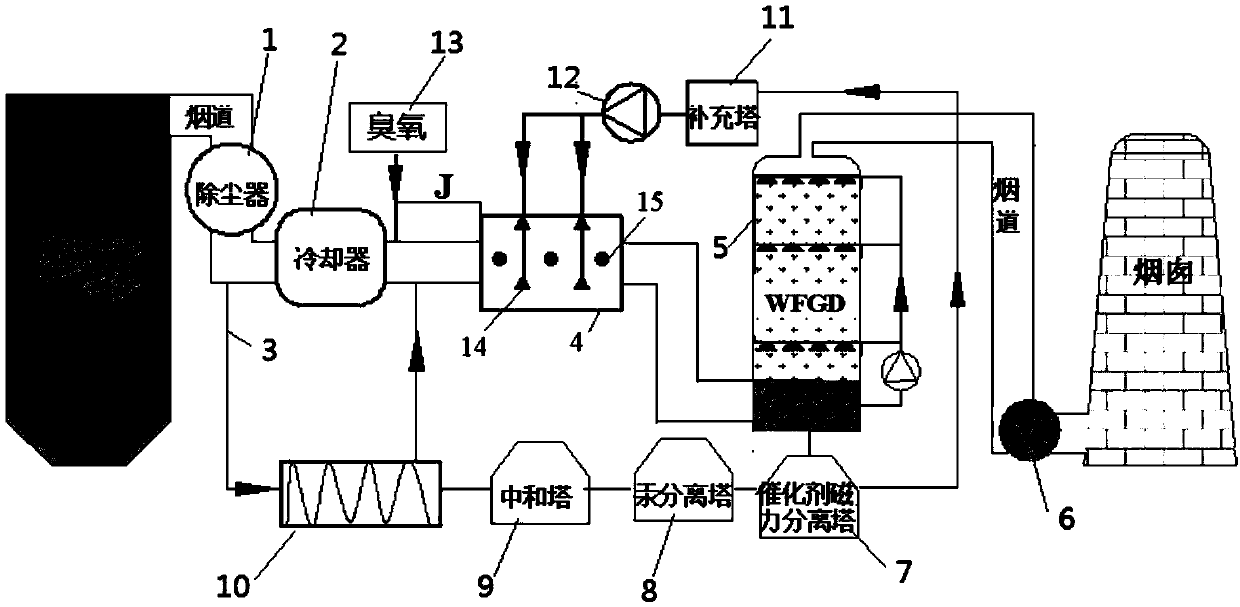

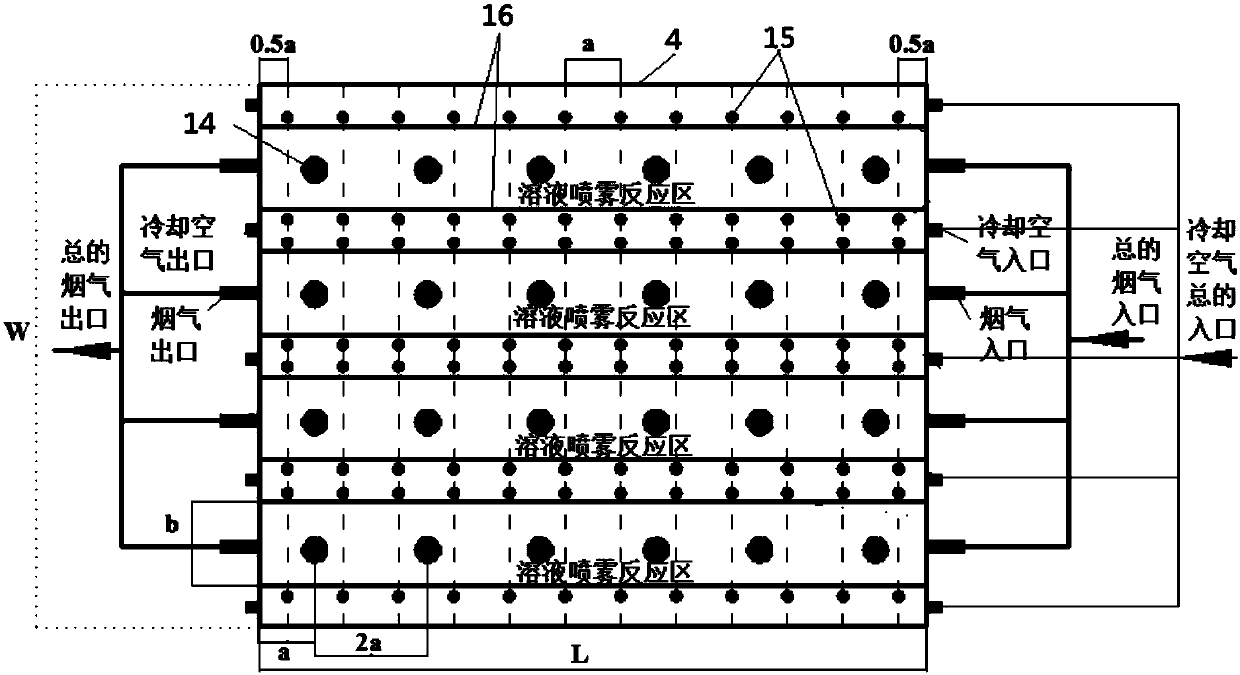

Method used

Image

Examples

Embodiment 1

[0054] Toluene content in exhaust gas is 400mg / m 3 , the ozone concentration is 200ppm, the flue gas temperature is 120°C, the molar concentration of potassium hydrogen persulfate compound salt is 0.2mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.2kg per cubic meter, and the microwave radiation power density is 300W / m 3 , the liquid-gas ratio is 3L / m 3 . The result of the small test is: the removal efficiency of toluene in flue gas is 42.8%.

Embodiment 2

[0056] Toluene content in exhaust gas is 400mg / m 3 , the ozone concentration is 300ppm, the flue gas temperature is 120°C, the molar concentration of potassium hydrogen persulfate compound salt is 0.3mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.3kg per cubic meter, and the microwave radiation power density is 600W / m 3 , the liquid-gas ratio is 3L / m 3 . The result of the small test is: the removal efficiency of toluene in the flue gas is 54.1%.

Embodiment 3

[0058] Toluene content in exhaust gas is 400mg / m 3 , the ozone concentration is 300ppm, the flue gas temperature is 120°C, the molar concentration of potassium hydrogen persulfate compound salt is 0.6mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.4kg per cubic meter, and the microwave radiation power density is 900W / m 3 , the liquid-gas ratio is 5L / m 3 . The result of the small test is: the removal efficiency of toluene in the flue gas is 85.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com