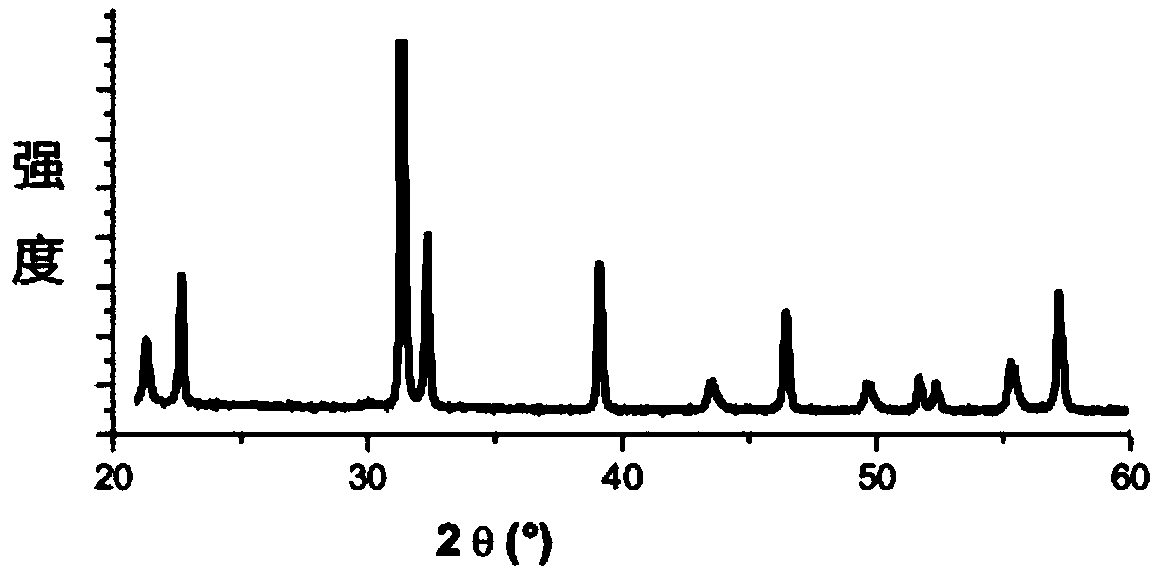

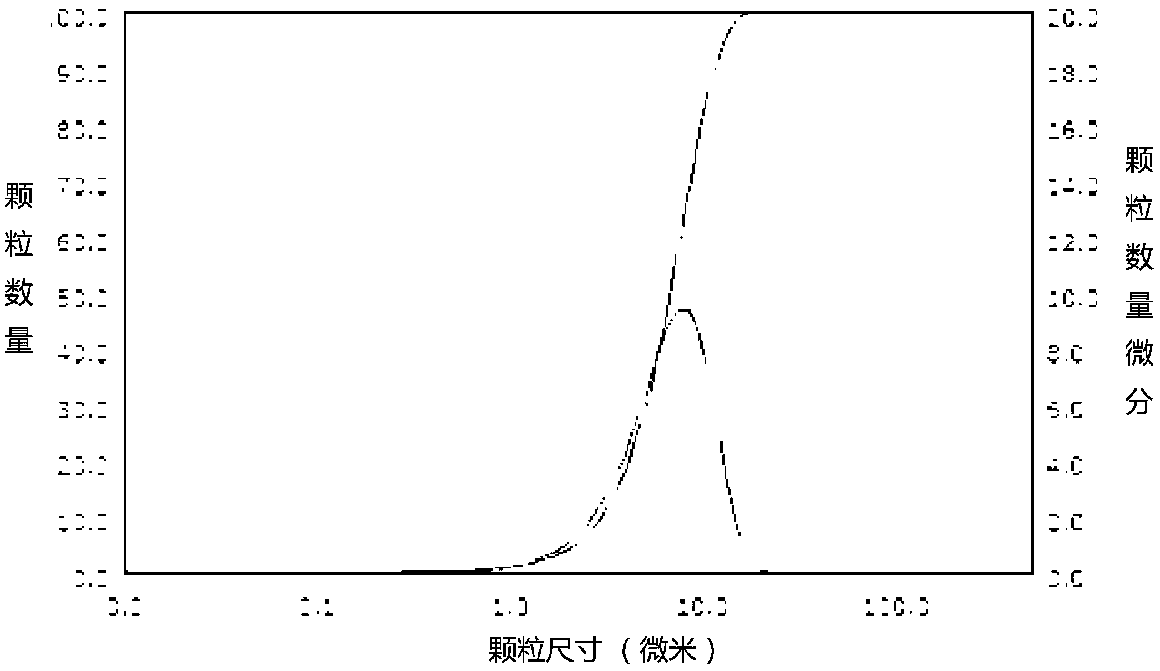

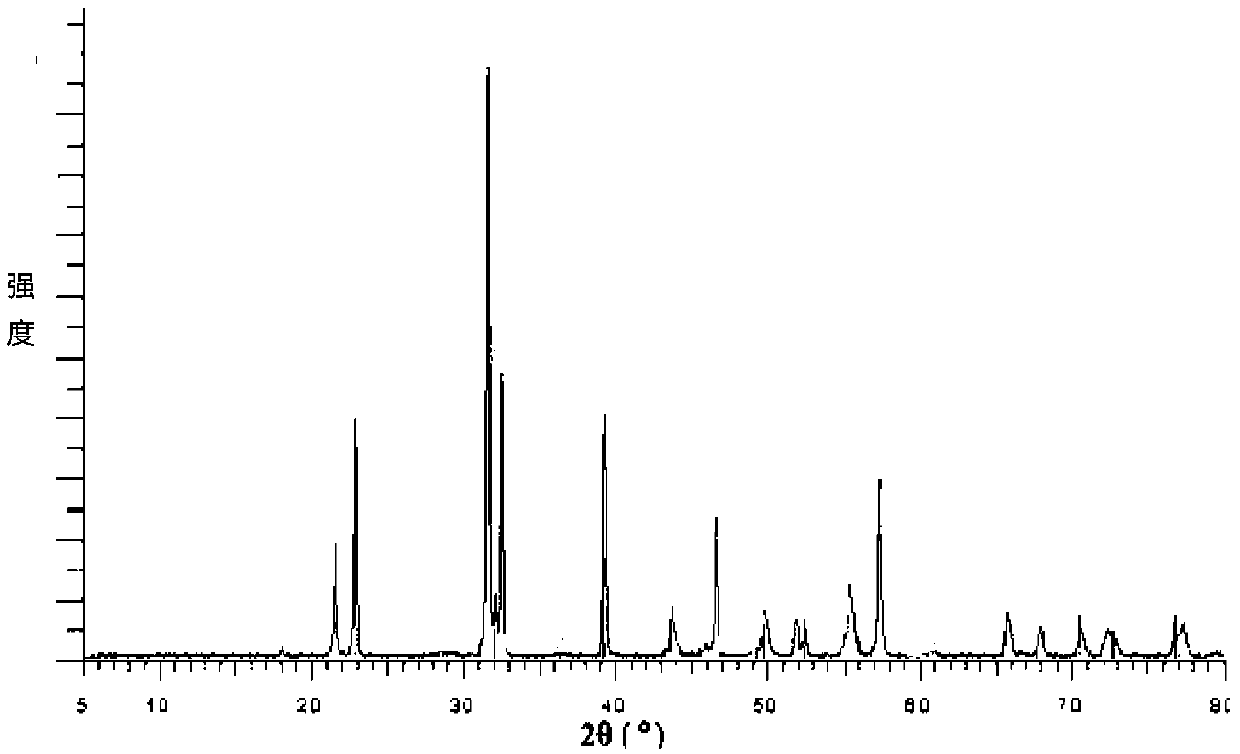

Method for preparing perovskite structure Pb1-xSnxTiO3 ceramic powder

A technology of perovskite structure and ceramic powder is applied in the field of preparing perovskite structure Pb1-xSnxTiO3 ceramic powder, which can solve the problems of easy occurrence of impurity phase, unsatisfactory particle size distribution, insufficient powder purity, etc., and achieves short reaction time. , Inhibition of PbSnO3, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation perovskite structure Pb 0.85 sn 0.15 TiO 3 The method for ceramic powder, comprising the following steps:

[0028] (1) The preparation of mineralizer solution: preparation concentration is the KOH solution of 2.5mol / L;

[0029] (2) Preparation of raw materials: according to the chemical formula Pb 0.85 sn 0.15 TiO 3 , weigh titanium oxide, stannous chloride and lead oxide for batching, mix the weighed raw materials to form perovskite ceramic particles, and prepare a solvent with a volume ratio of 95% ethanol and deionized water at a volume ratio of 2.5:1 , adding the above-mentioned solvent to the perovskite ceramic particles, the amount of the solvent is at least submerged in the perovskite ceramic particles, and the raw materials are mixed uniformly by magnetic stirring to obtain a mixed solution;

[0030] (3) Preparing the precursor solution: heating the mineralizer obtained in step (1) and the mixed solution obtained in step (2) to 75° C....

Embodiment 2

[0034] A kind of preparation perovskite structure Pb 0.9 sn 0.1 TiO 3 The method for ceramic powder, comprising the following steps:

[0035] (1) preparation of mineralizer solution: preparation concentration is the hydrochloric acid solution of 5mol / L;

[0036] (2) Preparation of raw materials: according to the chemical formula Pb 0.9 sn 0.1 TiO 3 , weigh lead nitrate, 2-ethylhexanoic acid stannous, butyl titanate for batching, mix the weighed raw materials to form perovskite ceramic particles, the volume ratio of ethanol and deionized water is 95% by volume Prepare a solvent for 2.5:1, add the above-mentioned solvent to the perovskite ceramic particles, the amount of the solvent is at least submerged in the perovskite ceramic particles, and mix the raw materials evenly by magnetic stirring to obtain a mixed solution;

[0037] (3) Preparing the precursor solution: heating the mineralizer obtained in step (1) and the mixed solution obtained in step (2) to 80° C., and the...

Embodiment 3

[0041] A kind of preparation perovskite structure Pb 0.4 sn 0.6 TiO 3 The method for ceramic powder, comprising the following steps:

[0042] (1) preparation of mineralizer solution: preparation concentration is the nitric acid solution of 1.2mol / L;

[0043] (2) Preparation of raw materials: according to the chemical formula Pb 0.4 sn 0.6 TiO 3 , weigh titanium oxide, tin sulfide, and lead oxide for batching, mix the raw materials weighed to form perovskite ceramic particles, and prepare a solvent with a volume ratio of 95% ethanol and deionized water as 2.5:1 to The above-mentioned solvent is added to the perovskite ceramic particles, the amount of the solvent is at least submerged in the perovskite ceramic particles, and the raw materials are mixed evenly by magnetic stirring to obtain a mixed solution;

[0044] (3) Preparing the precursor solution: heating the mineralizer obtained in step (1) and the mixed solution obtained in step (2) to 80° C., and then adding the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com