Imidazole sulfonate ionic liquid flame retardant containing DOPO and preparation method and application of imidazole sulfonate ionic liquid flame retardant

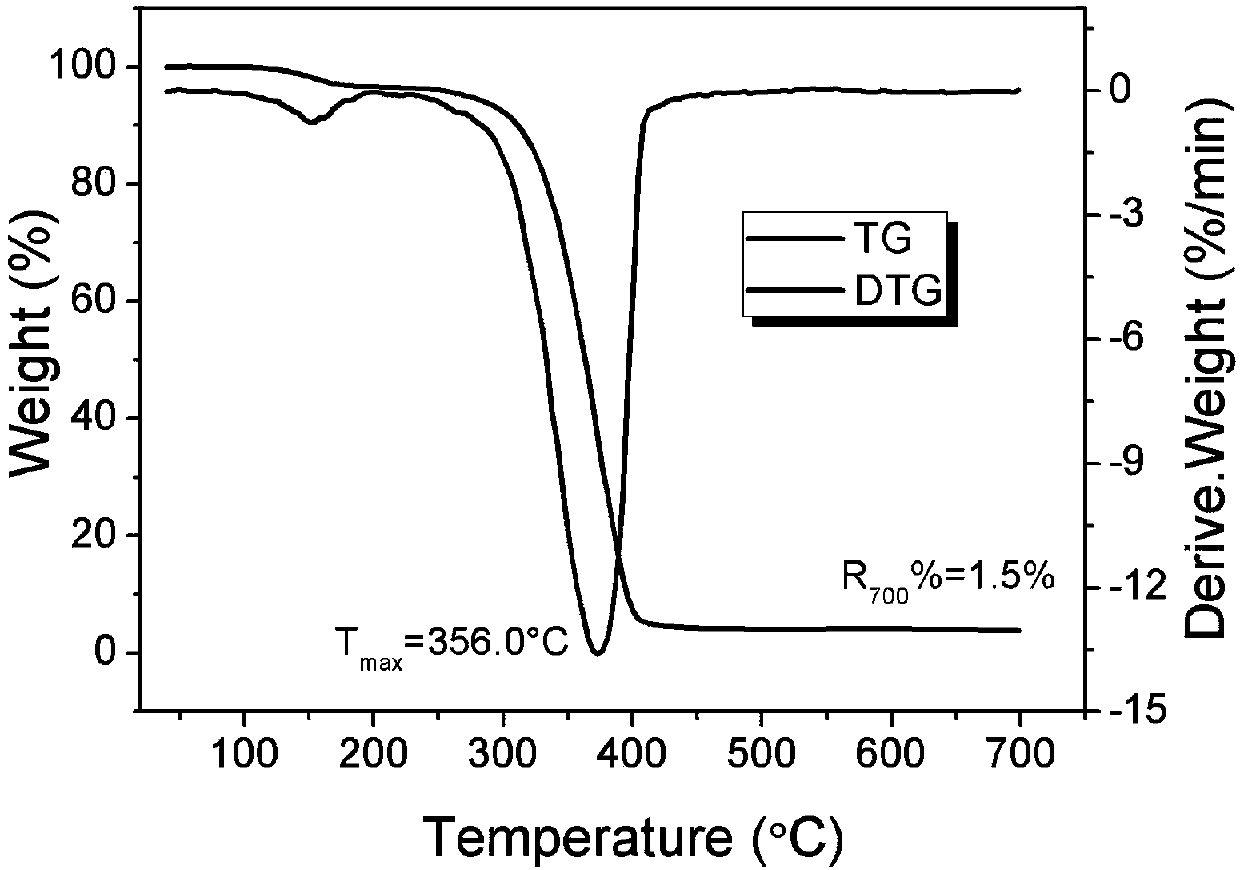

A technology of imidazole sulfonate and ionic liquid, which is applied in the field of flame retardancy, can solve the problems such as the decline in the mechanical properties of flame-retardant epoxy and poor compatibility, and achieve the effects of excellent thermal stability, wide source of raw materials, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

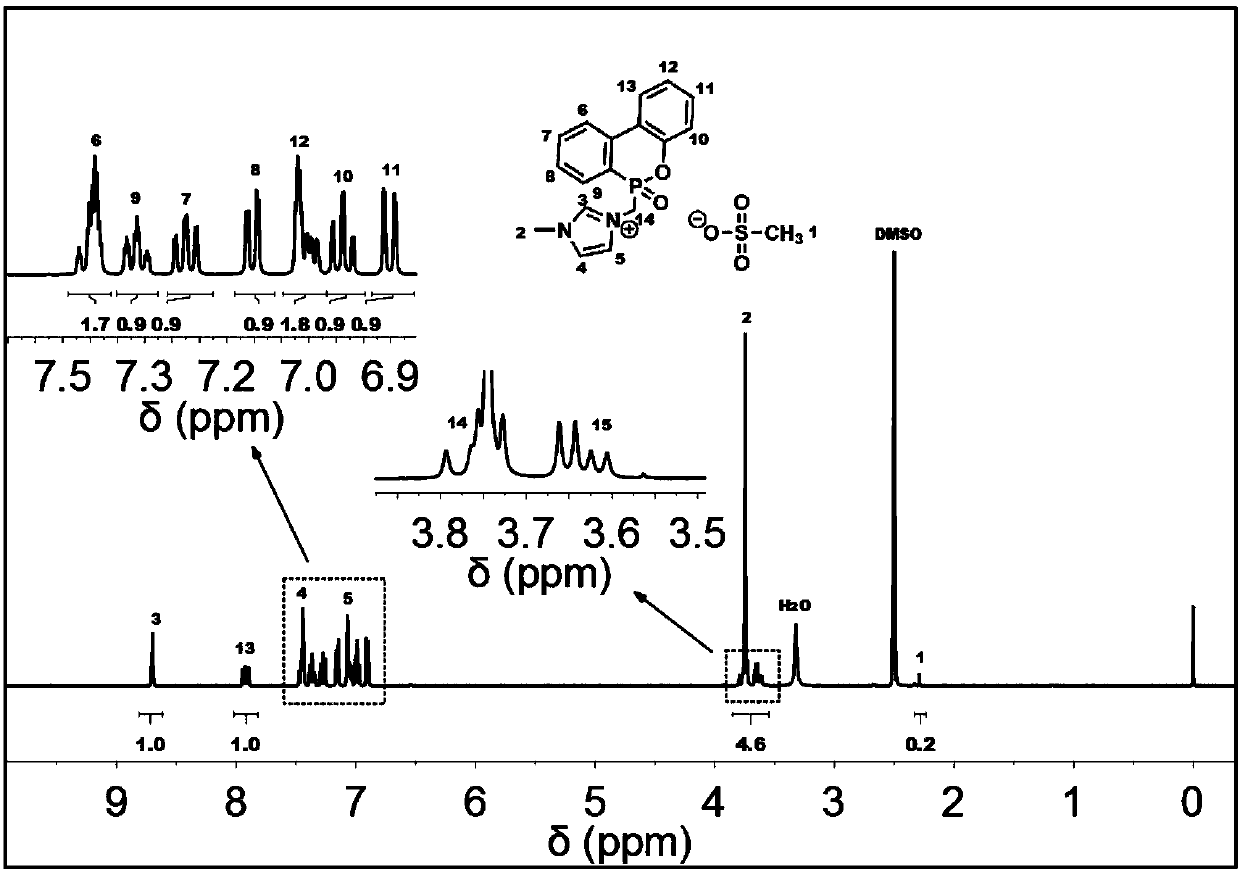

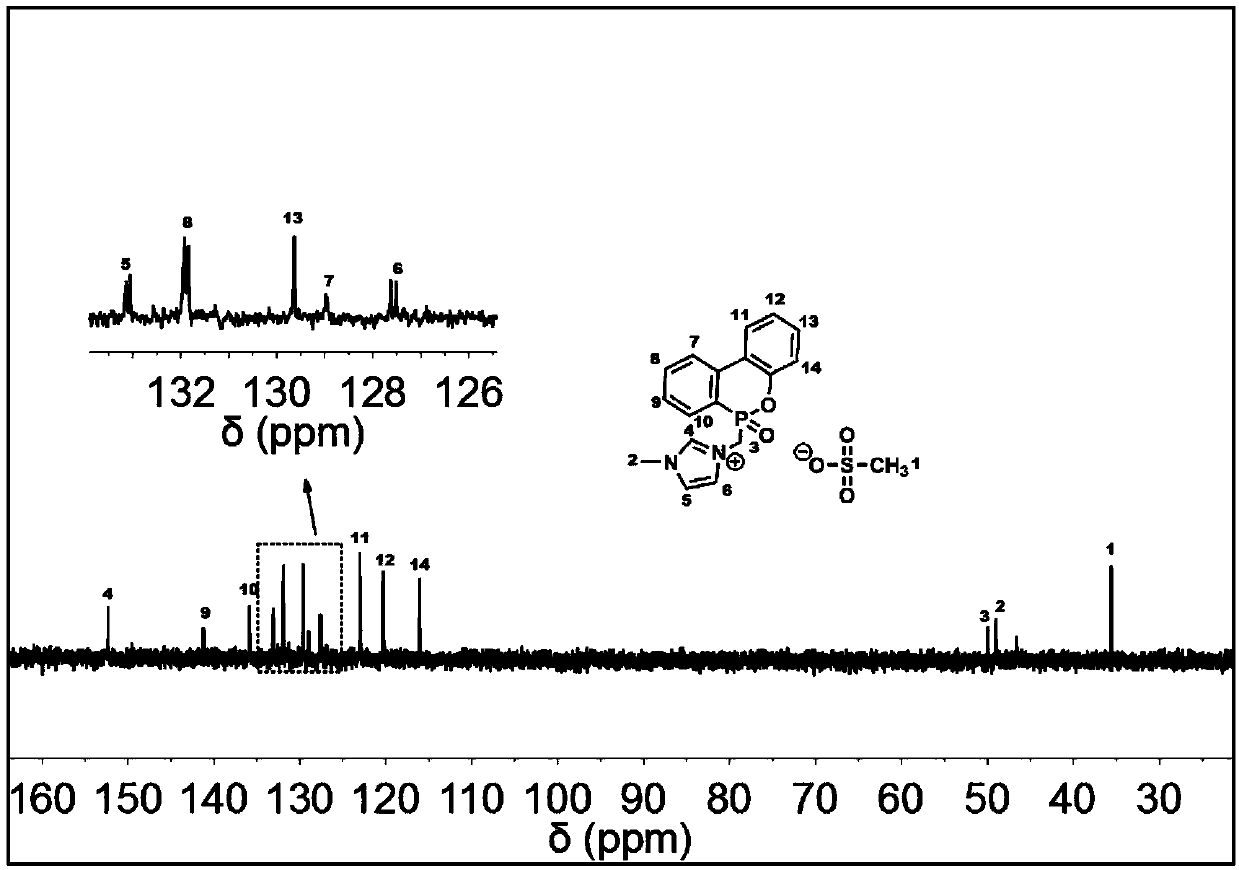

Method used

Image

Examples

Embodiment 1

[0042] 1) in N 2Under protection, add 1mol DOPO into 500ml solvent xylene, raise the temperature to 90°C, and mechanically stir for 30 minutes. After DOPO is completely dissolved in xylene, continue stirring for 10 minutes, and then slowly add 1mol~2mol of paraformaldehyde to maintain at React at 80°C for 5h to 8h. After the reaction, filter with suction and wash with deionized water for 3 to 5 times. A clean white sandy solid was obtained, irradiated by an infrared lamp for 4-6 hours, and then dried in a vacuum oven at 80° C. for 10 hours, with a yield of 96%. It was named DOPO-OH, and its structure was as follows:

[0043]

[0044] 2) in N 2 Under protection, dissolve 0.5mol DOPO-OH in 200ml dichloromethane, add 0.5mol triethylamine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol methanesulfonyl chloride dropwise with a dropping funnel, drop The addition time was controlled within 1 hour, and after the dropwise addition, the reaction was carr...

Embodiment 2

[0050] 1) in N 2 Under protection, add 1mol DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) into 500ml solvent xylene, heat up to 90°C, stir mechanically for 30min, and wait until DOPO is completely Dissolve in toluene, continue to stir for 10 minutes, then slowly add 1 mol of paraformaldehyde, and maintain the reaction at 80°C for 5h to 8h. After the reaction, filter with suction and wash with ethanol for 3 to 5 times. A clean white sandy solid was obtained, which was dried under infrared light for 4-6 hours, and then dried in a vacuum oven at 80°C for 10 hours, with a yield of 96%. It was named DOPO-OH, and its structure was as follows:

[0051]

[0052] 2) in N 2 Under protection, dissolve 0.5mol DOPO-OH in 200ml acetonitrile, add 0.5mol triethylamine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol p-toluenesulfonate dissolved in acetonitrile dropwise with a dropping funnel Acyl chloride, the dropwise addition time is controlled wi...

Embodiment 3

[0058] 1) in N 2 Under protection, add 1mol DOPO to 500ml solvent xylene, raise the temperature to 90°C, and stir mechanically for 30min. After DOPO is completely dissolved in xylene, continue stirring for 10min, then slowly add 1mol of paraformaldehyde, and maintain at 80°C Under the conditions of reaction 5h ~ 8h. After the reaction, filter with suction and wash with deionized water for 3 to 5 times to obtain a clean white sandy solid. Dry it with an infrared lamp for 4 to 6 hours, and then dry it in a vacuum oven at 80°C for 10 hours. The yield is 96%. It is named DOPO-OH. The structure is as follows:

[0059]

[0060] 2) in N 2 Under the condition of protective gas, dissolve 0.5mol DOPO-OH in 200ml ethanol, add 0.5mol pyridine, stir mechanically at a rate of 400r / min for 10min, then slowly add 0.5mol propylsulfonyl chloride dropwise with a dropping funnel, drop Adding time was controlled within 1 hour, and after the dropwise addition, the reaction was carried out at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com