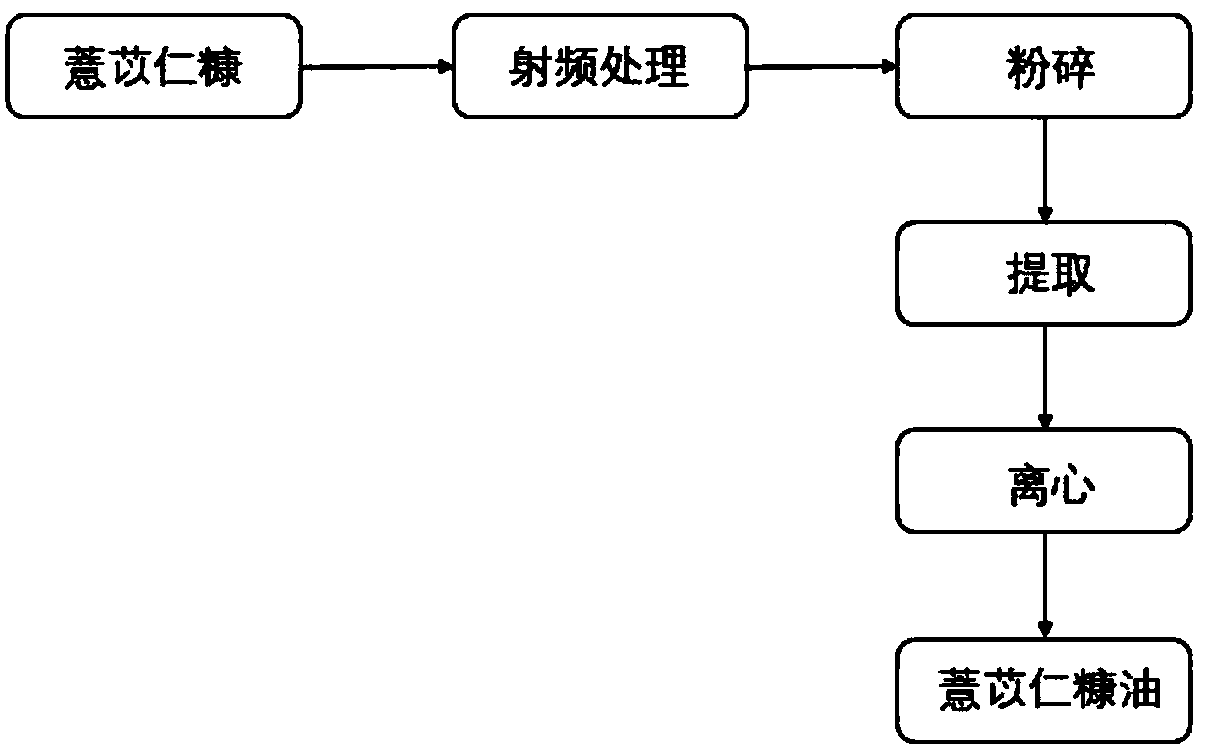

Method for extracting active oil from semen coicis bran by radio-frequency enzyme killing and ethanol assistance

A coix seed bran and auxiliary extraction technology, which is applied in the field of fine processing of agricultural and sideline products, can solve the problems of unfavorable comprehensive processing of rice bran, difficulty in achieving stable rice bran, and protein denaturation of rice bran, so as to shorten the oil production cycle, eliminate the use of enzymes, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Extraction of Coix Seed Bran Active Oil

[0035] The fresh coix seed bran is pulverized without any pretreatment, and pulverized with a Chinese medicine pulverizer to a volume average particle size of about 200μm, and then pulverized with a grinder to a volume average particle size of about 45μm to obtain the raw material for oil extraction.

[0036] The oil extraction raw materials were adjusted at 60°C according to the material-liquid ratio of 1 (g): 5 (mL), the concentration of the ethanol aqueous solution was 30% (v / v), and the pH of the system was adjusted to 7.0 for oil extraction. The reaction time was 2 hours. After the reaction is finished, it is centrifuged at 5000 rpm for 15 minutes to obtain the incompatible four phases-free oil, emulsion, water phase, and residue phase. The free coix seed chaff active oil is separated and weighed.

[0037] The free yield is 50.52%, the acid value is 70.5(KOH) / (mg / g), and the fat content of the residue phase accounts for ...

Embodiment 2

[0038] Example 2 Effect of Radio Frequency Technology on the Extraction of Coix Seed Bran Active Oil

[0039] Use radio frequency technology to inactivate enzymes from fresh coix seed chaff. The radio frequency of the equipment is 27.1MHZ. Power is 6KW, temperature is 60℃, time is 20min; power is 6KW, temperature is 60℃, time is 8min; power is 6KW, temperature is 120℃, time is 20min; power is 6KW, temperature is 120℃, time is 8min; power is 12KW, temperature is 60℃, time is 20min; power is 12KW, temperature is 60℃, time is 8min; power is 12KW, temperature is 120℃, time is 20min; power is 12KW, temperature is 120℃, The time is 8 minutes; after the treatment, the coix seed chaff after the radio frequency treatment is collected.

[0040] The coix seed bran after radio frequency treatment is pulverized to a volume average particle size of about 210 μm using a traditional Chinese medicine pulverizer, and then pulverized to a volume average particle size of about 45 μm using a roller co...

Embodiment 3

[0045] Example 3 Effect of particle size on the extraction of active oil from coix seed bran

[0046] The fresh coix seed bran was inactivated by radio frequency technology, the radio frequency was 27.12MHZ, the power was 6KW, the temperature was 120°C, and the time was 12min. After the treatment, collect the coix seed chaff after radio frequency treatment.

[0047] The coix seed bran treated by radio frequency was pulverized to a volume average particle size of 500μm, 210μm, 186μm, 175μm, 160μm using a Chinese medicine pulverizer, and then pulverized to a volume average particle size of 200μm, 93μm, 45μm, 45μm, 20μm with a roller compactor. Around, get the raw material for oil extraction.

[0048] The oil extraction raw materials were adjusted at 60°C according to the material-liquid ratio of 1 (g): 5 (mL), the concentration of the ethanol aqueous solution was 30% (v / v), and the pH of the system was adjusted to 7.0 for oil extraction. The reaction time was 2 hours. After the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com