Central fluid supply system with self-cleaning function for hemodialysis and working method thereof

A hemodialysis and self-cleaning technology, applied in dialysis systems, suction devices, etc., can solve problems such as polluting the environment, threatening the safety of dialysis patients, and cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

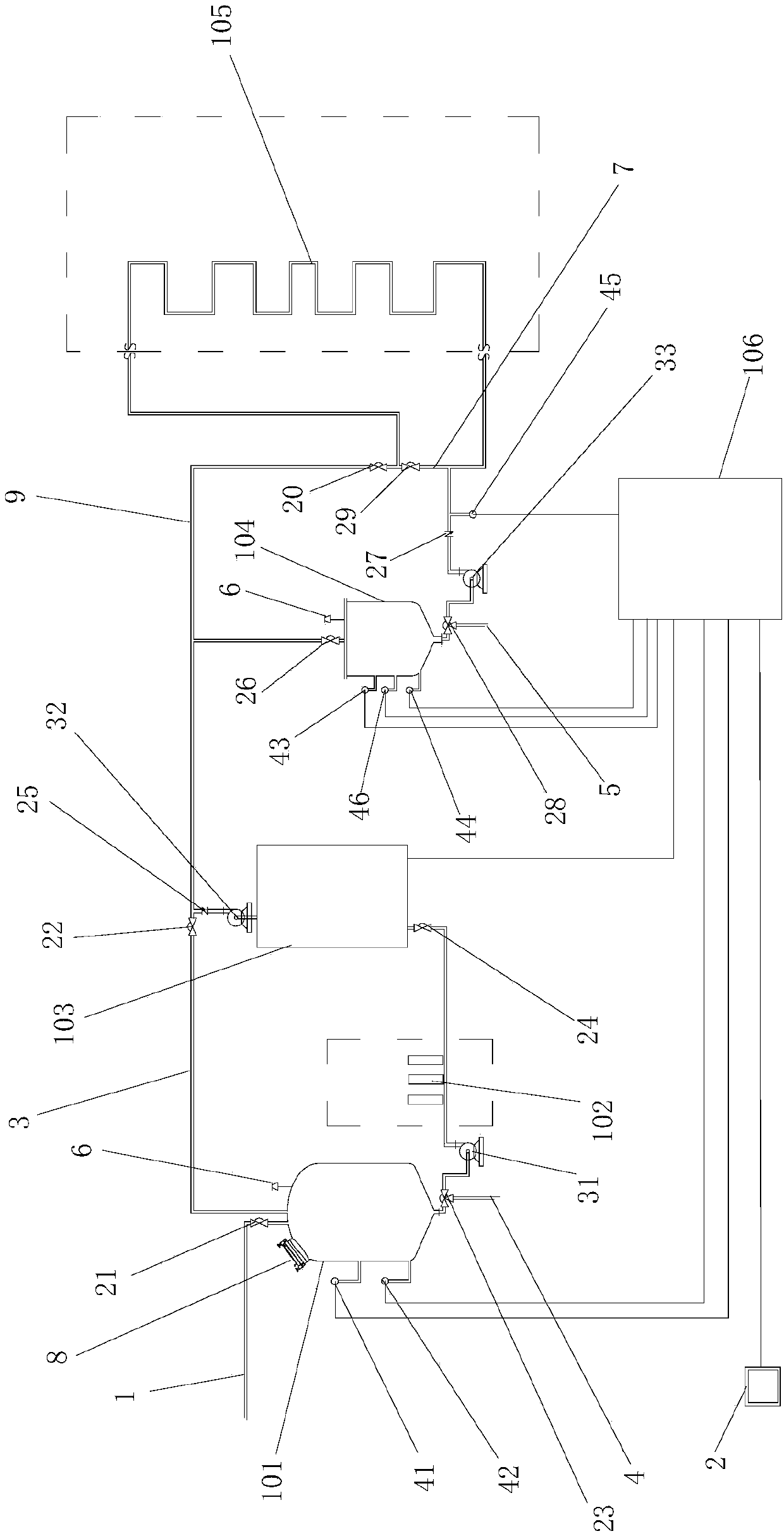

[0026] see figure 1 , figure 1 It is a structural schematic diagram of the online monitoring centralized liquid supply system of the present invention, including a control system 106 (single-chip microcomputer, central processing unit or PLC controller can be selected), a liquid crystal display 2, a remote monitoring server, a liquid distribution device, a disinfection device, a liquid storage device and An infusion pipeline 105 for connecting the liquid distribution device and the blood purification center.

[0027] The liquid distribution device includes a liquid distribution tank 101. The top of the liquid distribution tank 101 is provided with a water inlet 1 and a feeding port 8, which are used to feed dialysis water and required materials into the liquid distribution tank 101. Set the first valve 21 for controlling its on-off, the top of the liquid distribution tank 101 is also equipped with an ozone tail gas destroyer 6, which is used to eliminate the residual ozone in...

Embodiment 2

[0033] Taking the B concentrate in hemodialysis as an example, the working steps of the online monitoring centralized liquid supply system of the present invention are as follows:

[0034] A. The operation panel of the control system 106 selects the quantity and dilution ratio of the hemodialysis concentrate to be prepared, and controls the amount of water added for the corresponding dialysis water through the pressure sensor 42, and puts the hemodialysis B dry powder into the feeding port 8 of the liquid distribution tank 101, and passes through the machine Stir to completely dissolve the hemodialysis B dry powder, compare the conductivity of the concentrated solution through the conductivity sensor 42, confirm the ion concentration of the concentrated solution, and obtain qualified hemodialysis B concentrated solution, the first infusion pump 31 will pass the qualified blood The dialysis B concentrate flows through the filter 102 and the fourth valve 24 to reach the disinfect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com