Compound additive for improving intestinal tract health of piglets and preparation method thereof and application thereof

A compound additive and intestinal health technology, applied in application, additional food elements, animal feed, etc., can solve the problems that affect the development of pig industry, the reduction of feed remuneration, and low disease resistance, so as to improve the intestinal immunity of piglets , promote digestion and absorption, and repair the effect of intestinal mucosa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

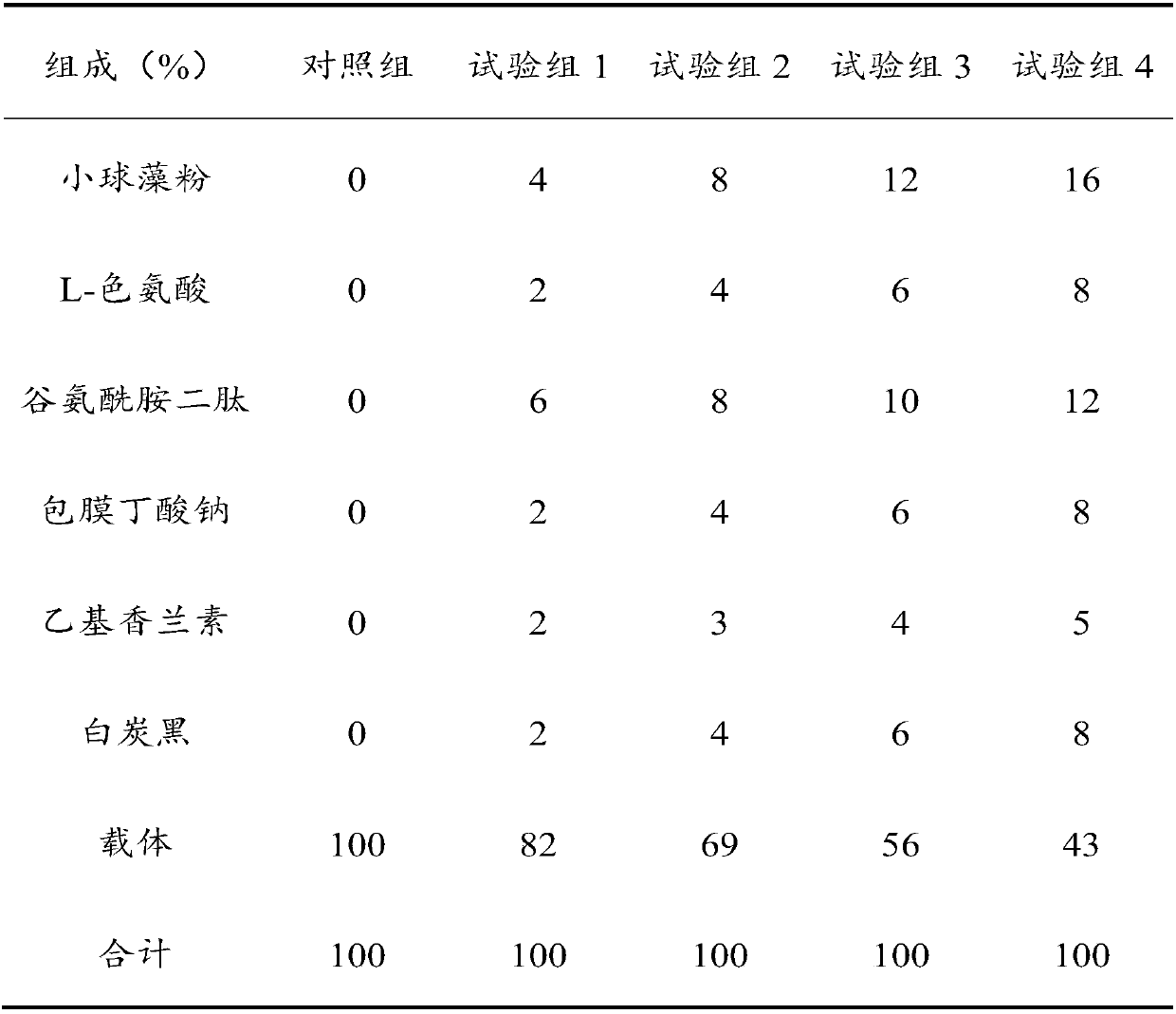

Embodiment 1

[0044] Mix the wall material and water at 65°C at a weight ratio of 2.5:5.5 to obtain a coating solution. Then, sodium butyrate was added at a rate of 8 g / min to every 20 mL of the coating liquid, homogenized, and spray-dried at 25° C. to obtain coated sodium butyrate. Among them, the weight ratio of sodium butyrate to the wall material is 1:2.5, and the wall material contains λ-carrageenan, 1,4-α-L-guluronic acid and calcium chloride with a weight ratio of 2:0.75:0.15 .

[0045] Pulverize the solid raw material to 80 orders, then the ethyl vanillin of 2 weight parts and the white carbon black of 2 weight parts are mixed to the porosity of white carbon black 3%, then with the chlorella powder of 4 weight parts, 2 A composite additive is obtained by mixing parts by weight of L-tryptophan, 6 parts by weight of glutamine dipeptide, 2 parts by weight of coated sodium butyrate and 82 parts by weight of rice husk powder.

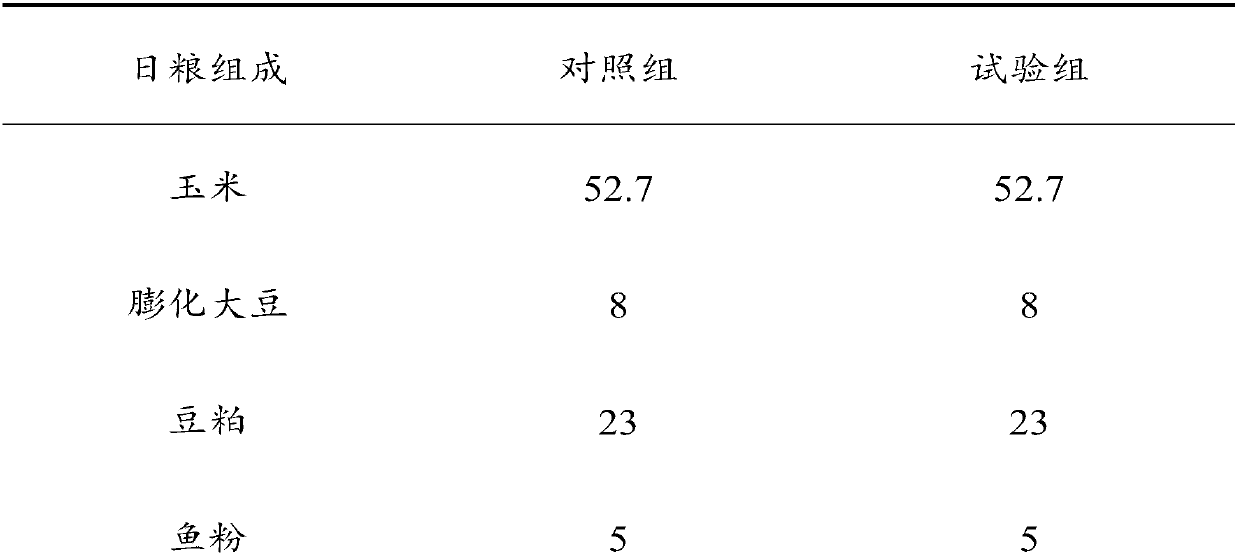

[0046] The above-mentioned compound additive is added to p...

Embodiment 2

[0048] Mix the wall material and water at 65°C at a weight ratio of 2.5:5.5 to obtain a coating solution. Then, sodium butyrate was added at a rate of 8 g / min to every 20 mL of the coating liquid, homogenized, and spray-dried at 25° C. to obtain coated sodium butyrate. Among them, the weight ratio of sodium butyrate to the wall material is 1:2.5, and the wall material contains λ-carrageenan, 1,4-α-L-guluronic acid and calcium chloride with a weight ratio of 2:0.75:0.15 .

[0049] Pulverize the solid raw material to 80 orders, then the ethyl vanillin of 5 parts by weight and the white carbon black of 8 parts by weight are mixed to the porosity of white carbon black is 3%, then with the chlorella powder of 16 parts by weight, 8 parts by weight A composite additive is obtained by mixing parts by weight of L-tryptophan, 12 parts by weight of glutamine dipeptide, 8 parts by weight of coated sodium butyrate and 43 parts by weight of rice husk powder.

[0050] The above-mentioned c...

Embodiment 3

[0052] Mix the wall material and water at 65°C at a weight ratio of 2.5:5.5 to obtain a coating solution. Then, sodium butyrate was added at a rate of 8 g / min to every 20 mL of the coating liquid, homogenized, and spray-dried at 25° C. to obtain coated sodium butyrate. Among them, the weight ratio of sodium butyrate to the wall material is 1:2.5, and the wall material contains λ-carrageenan, 1,4-α-L-guluronic acid and calcium chloride with a weight ratio of 2:0.75:0.15 .

[0053] Pulverize the solid raw material to 80 orders, then the ethyl vanillin of 3 weight parts and the white carbon black of 4 weight parts are mixed to the porosity of white carbon black is 3%, then with the chlorella powder of 8 weight parts, 4 A compound additive is obtained by mixing parts by weight of L-tryptophan, 8 parts by weight of glutamine dipeptide, 4 parts by weight of coated sodium butyrate and 69 parts by weight of rice husk powder.

[0054] The above-mentioned compound additive is added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com