Ceramic tooth 3D printing production method in dental restoration industry

A 3D printing and dental restoration technology, which is applied in dentistry, medical science, dental preparations, etc., can solve the problems of high labor dependence, poor quality stability, and unstable quality, and achieve labor cost reduction, fast production cycle, and raw materials. The effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

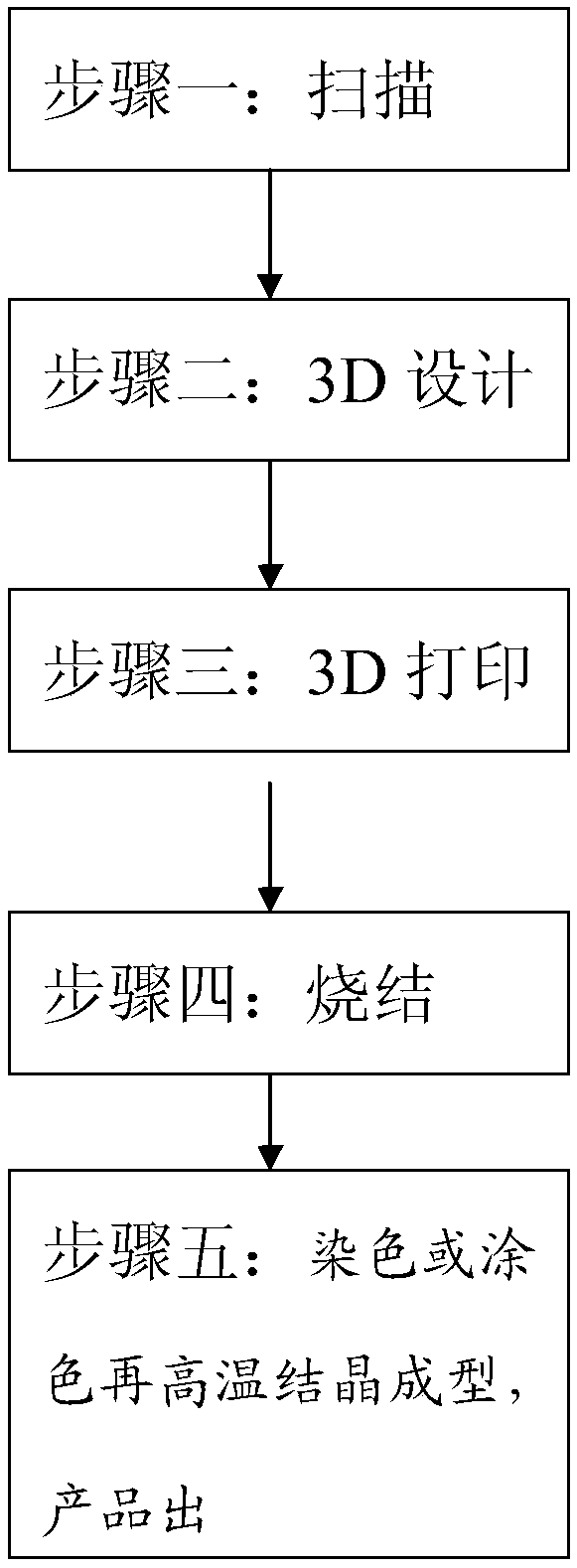

[0033] see figure 1 As shown, the present invention is about a production method of ceramic tooth 3D printing in the dental restoration industry,

[0034] Step 1: The doctor obtains the plaster model and scans the plaster model, or the doctor directly scans the patient's mouth to obtain the scan data; the scan data is sent to the ceramic tooth processing center by mail;

[0035] Step 2: The ceramic tooth processing center uses dental CAD design software to design a 3D ceramic tooth simulation model file for the ceramic tooth shape according to the production type requirements proposed by the doctor;

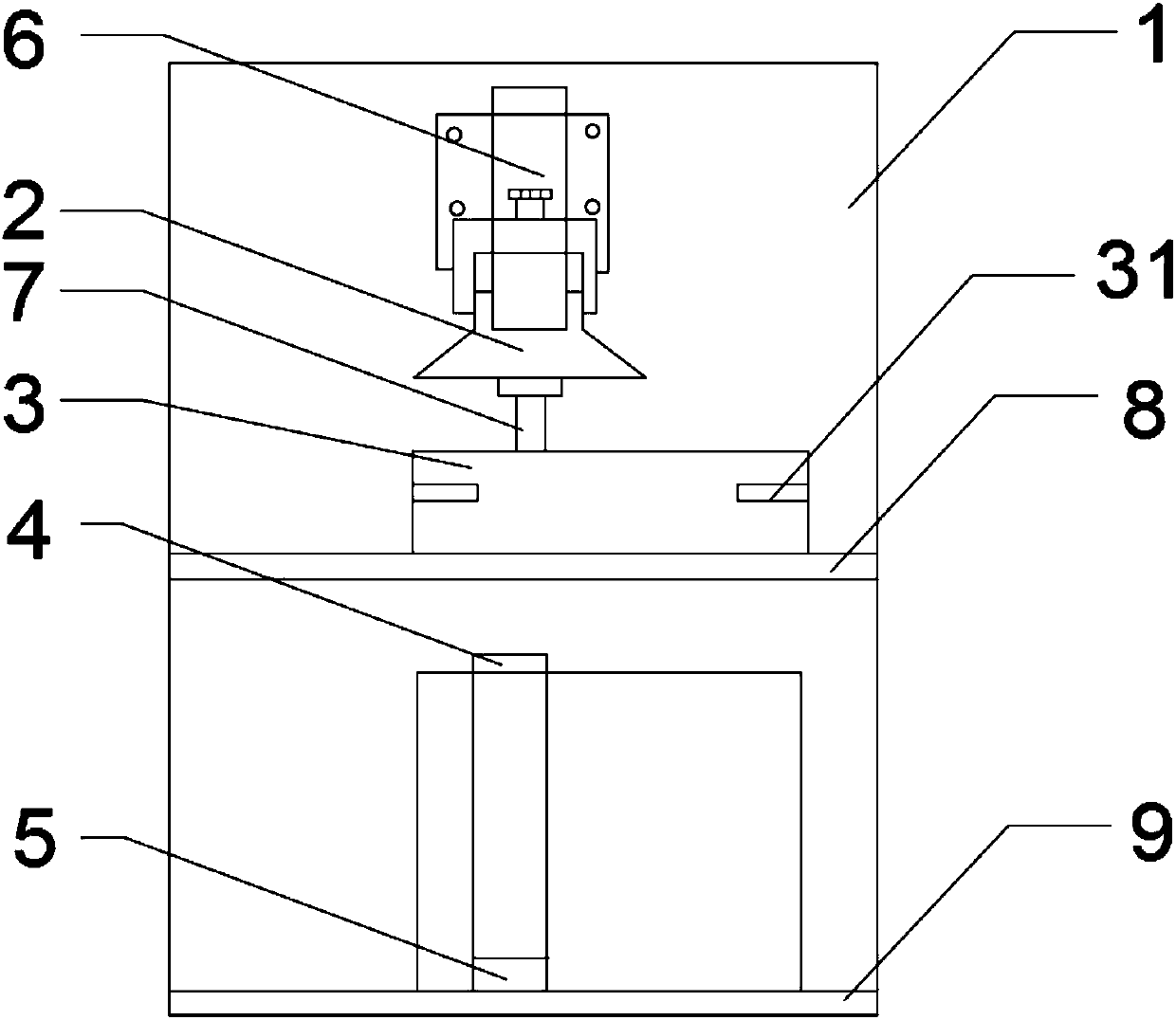

[0036] Step 3: Transfer the data of the 3D ceramic tooth simulation model file to the 3D printing device, place the ceramic slurry in the 3D printing tank, make the liquid level of the ceramic slurry reach the preset height, and simulate the designed 3D ceramic tooth After the model file is sliced and supported by the software contour, it is cured layer by layer by the UV ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com