A kind of bead structure nano zero-valent iron/cellulose composite material and its application

A technology of nano-zero-valent iron and nano-cellulose, which is applied in other chemical processes, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of reducing the activity of nano-zero-valent iron, high surface energy, and reduced activity. Achieve good stabilization and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

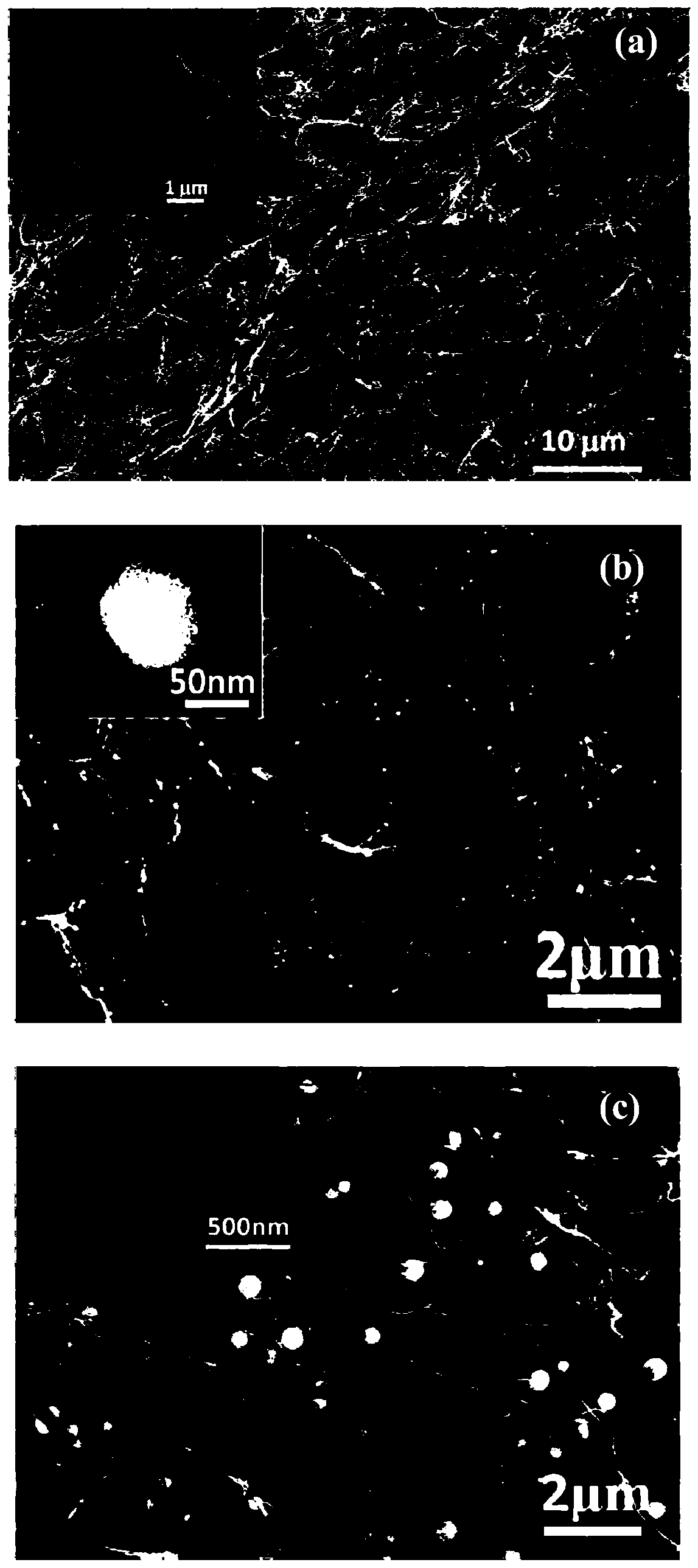

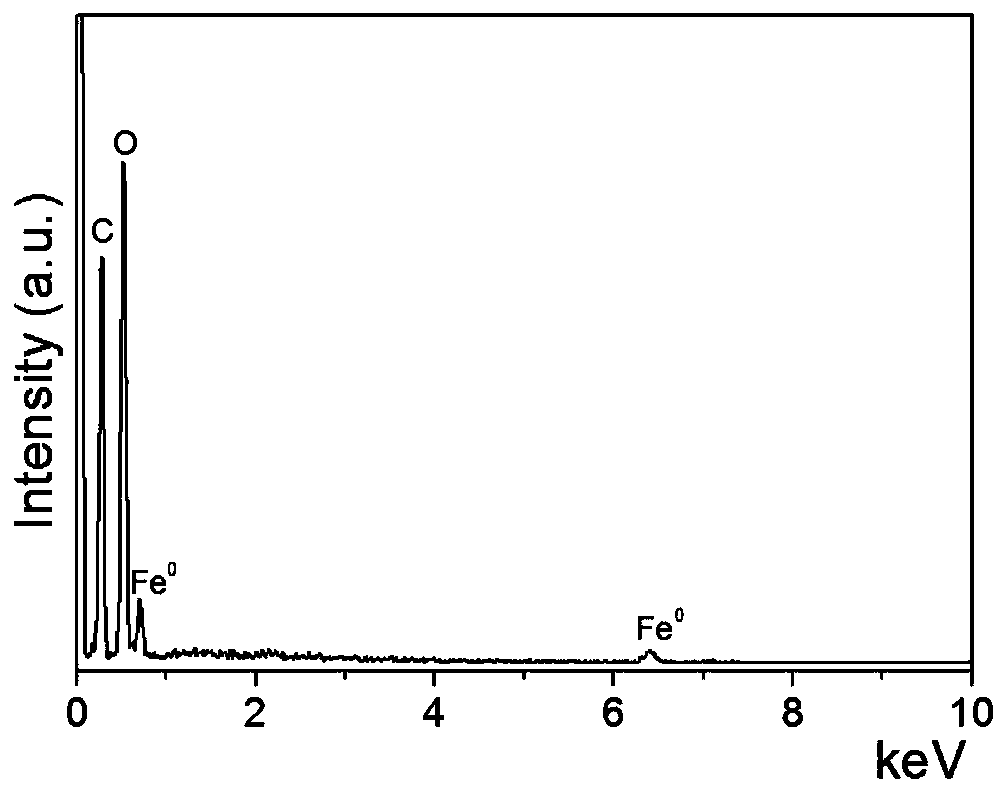

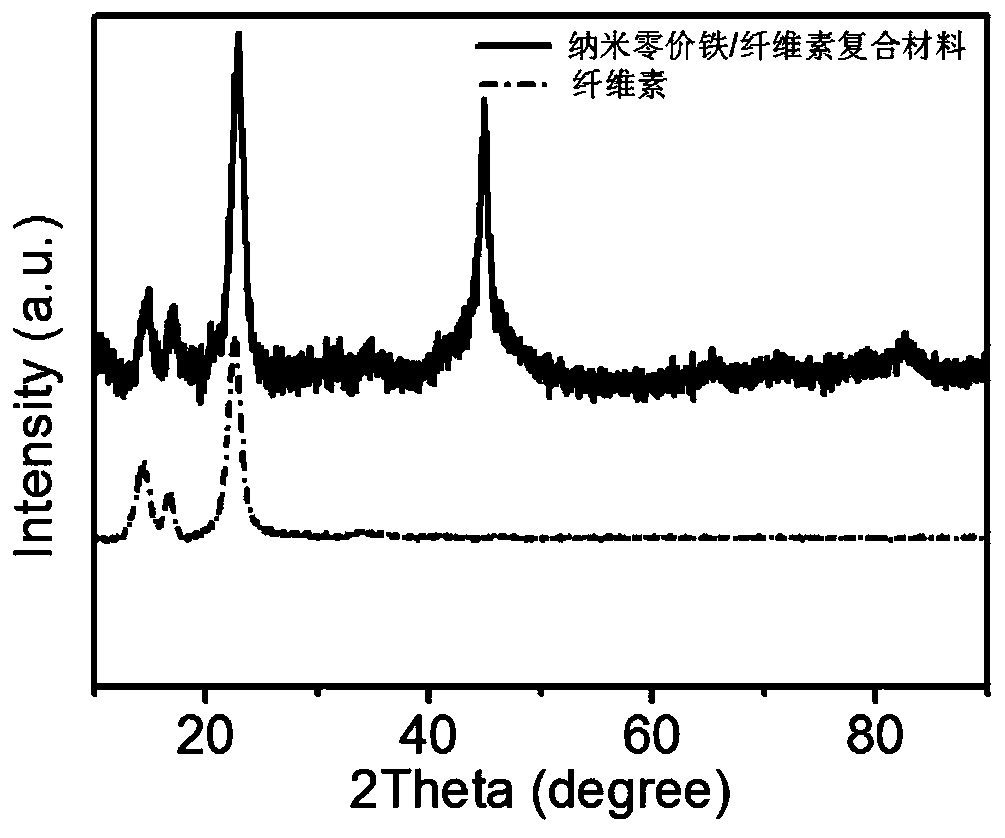

[0029] A kind of bead structure nanometer zero valent iron / cellulose composite material, its preparation method comprises the following steps:

[0030] Step A, according to the ratio of 100mL deionized water and 1mL mass fraction of 25% glutaraldehyde per 0.4g nanocellulose, the nanocellulose is dispersed in deionized water, and the pH value of the solution is adjusted to 2 by adding hydrochloric acid , then add glutaraldehyde with a mass fraction of 25%, and carry out a hydrothermal reaction at a hydrothermal temperature of 160° C. for 5 hours after dispersion, thereby obtaining a crosslinked nanocellulose hydrogel; The hydrogels were freeze-dried to produce three-dimensional nanocellulose with micro / nanoporous structures.

[0031] Step B, according to every 0.005~0.02mol FeSO 4 Using the proportion of 60mL water, the FeSO 4 dissolved in water to obtain FeSO 4 Aqueous solution; according to every 0.005 ~ 0.02mol FeSO 4 Using a ratio of 0.2 g of the three-dimensional nanoc...

Embodiment 1

[0048] A kind of bead structure nanometer zero valent iron / cellulose composite material, its preparation method comprises the following steps:

[0049] Step a1, drying the corn stalks first, then crushing them with a pulverizer, and passing through a 60-mesh sieve to obtain corn stalk powder whose particle size exceeds 60 mesh sieves; take 10 g of the corn stalk powder and put it into a 250 mL round bottom flask , and then add 150mL of toluene and ethanol mixed solution (the toluene and ethanol mixed solution is formed by mixing toluene and ethanol according to the volume ratio of 2:1), and after stirring for 6 hours, suction filtration and washing, so as to obtain the first reactant.

[0050] Step b1, add 150mL acetic acid-acidified sodium chlorite solution to the first reactant (the acetic acid-acidified sodium chlorite solution can be made of acetic acid and sodium chlorite according to the amount of 6g sodium chlorite used for every 22.5mL acetic acid Proportion mixed), an...

Embodiment 2

[0058] A kind of bead structure nanometer zero valent iron / cellulose composite material, its preparation method comprises the following steps:

[0059] Step a2, drying the corn stalks first, then crushing them with a pulverizer, and passing through a 60-mesh sieve to obtain corn stalk powder whose particle size exceeds 60 mesh sieves; take 10 g of the corn stalk powder and put it into a 250 mL round bottom flask , and then add 150mL of toluene and ethanol mixed solution (the toluene and ethanol mixed solution is formed by mixing toluene and ethanol according to the volume ratio of 2:1), and after stirring for 6 hours, suction filtration and washing, so as to obtain the first reactant.

[0060] Step b2, add 150mL acetic acid-acidified sodium chlorite solution to the first reactant (the acetic acid-acidified sodium chlorite solution can be made of acetic acid and sodium chlorite according to the amount of 6g sodium chlorite used for every 22.5mL acetic acid Proportion mixed), an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com