A kind of method for preparing magnesium hydroxide nano film by hydration of magnesium oxide

A magnesium oxide hydration and magnesium hydroxide technology, applied in the direction of magnesium hydroxide, can solve the problems of low investment, limited industrial production, long reaction time, etc., achieve broad development prospects, realize large-scale industrial production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

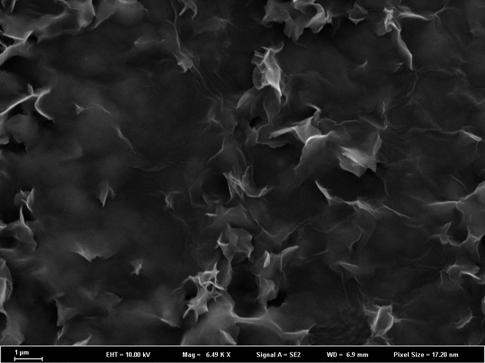

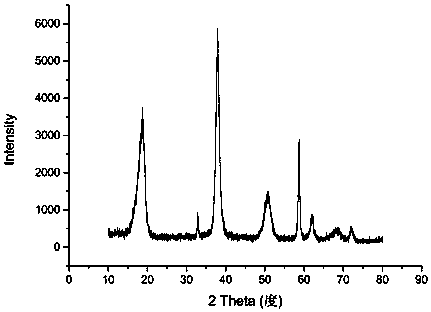

[0030] Take Δn Cl - Put 2g of 10mol / kg active magnesium oxide into a beaker, add 20ml of ethanol, put it in an ultrasonic cleaning machine with ultrasonic frequency and power set to 20kHz and 50w respectively, and carry out dispersion treatment for 10min. Magnesium suspension was added dropwise to 150ml distilled water at a rate of 3ml / min for hydration reaction for 1h, and 10ml of triethanolamine solution with a concentration of 10wt% was added at one time while the magnesium oxide suspension was started to be added dropwise, and the hydration process continued High-shear emulsification and stirring, the stirring rate is set to 2000r / min, after the hydration reaction, suction filtration, washing, filtration, and finally drying at 105 ° C for 5 hours to obtain a uniformly distributed, high-transparency single-layer nano-scale magnesium hydroxide film . The SEM photos and XRD patterns of the product are as follows figure 1 and figure 2 shown.

Embodiment 2

[0032] Take Δn Cl -Put 2 g of 15 mol / kg active magnesium oxide into a beaker, add 10 ml of ethanol, put it in an ultrasonic cleaning machine with ultrasonic frequency and power set to 28 kHz and 100 w, respectively, and carry out dispersion treatment for 15 min. Magnesium suspension was added dropwise to 200ml distilled water at a rate of 2ml / min for hydration reaction for 1.5h, and at the 5th minute of reaction, 5ml of ethylene glycol solution with a concentration of 8wt% was added at a rate of 1ml / min, and the hydration continued Ultrasonic treatment, the frequency and power of ultrasonic waves are set to 40kHz and 100w respectively. After the hydration reaction is completed, suction filtration, washing, filtration, and finally drying at 105°C for 5 hours to obtain uniformly distributed, high-transparency single-layer nano-scale magnesium hydroxide film. The SEM photos and XRD patterns of the product are as follows image 3 and Figure 4 shown.

Embodiment 3

[0034] Take Δn Cl - Put 2g of 25mol / kg active magnesium oxide into a beaker, add 10ml of isopropanol, put it in an ultrasonic cleaning machine with ultrasonic frequency and power set to 40kHz and 50w respectively, and carry out dispersion treatment for 10min. The magnesia suspension was added dropwise to 200ml distilled water at a rate of 1ml / min for hydration reaction for 2h, and at the 10th minute of reaction, 8ml of monoethanolamine solution with a concentration of 10wt% was added at a rate of 3ml / min, and the hydration was carried out High-shear emulsification and stirring, the stirring rate is set to 3000r / min, after the hydration reaction is completed, suction filtration, washing, filtration, and finally drying at 105°C for 5 hours to obtain a uniformly distributed, high-transparency single-layer nano-scale magnesium hydroxide film . The SEM photos and XRD patterns of the product are as follows Figure 5 and Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com