9, 9, 10, 10-tetraoxygen-thianthrene-contained water/alcohol-soluble polymer as well as preparation method and application thereof

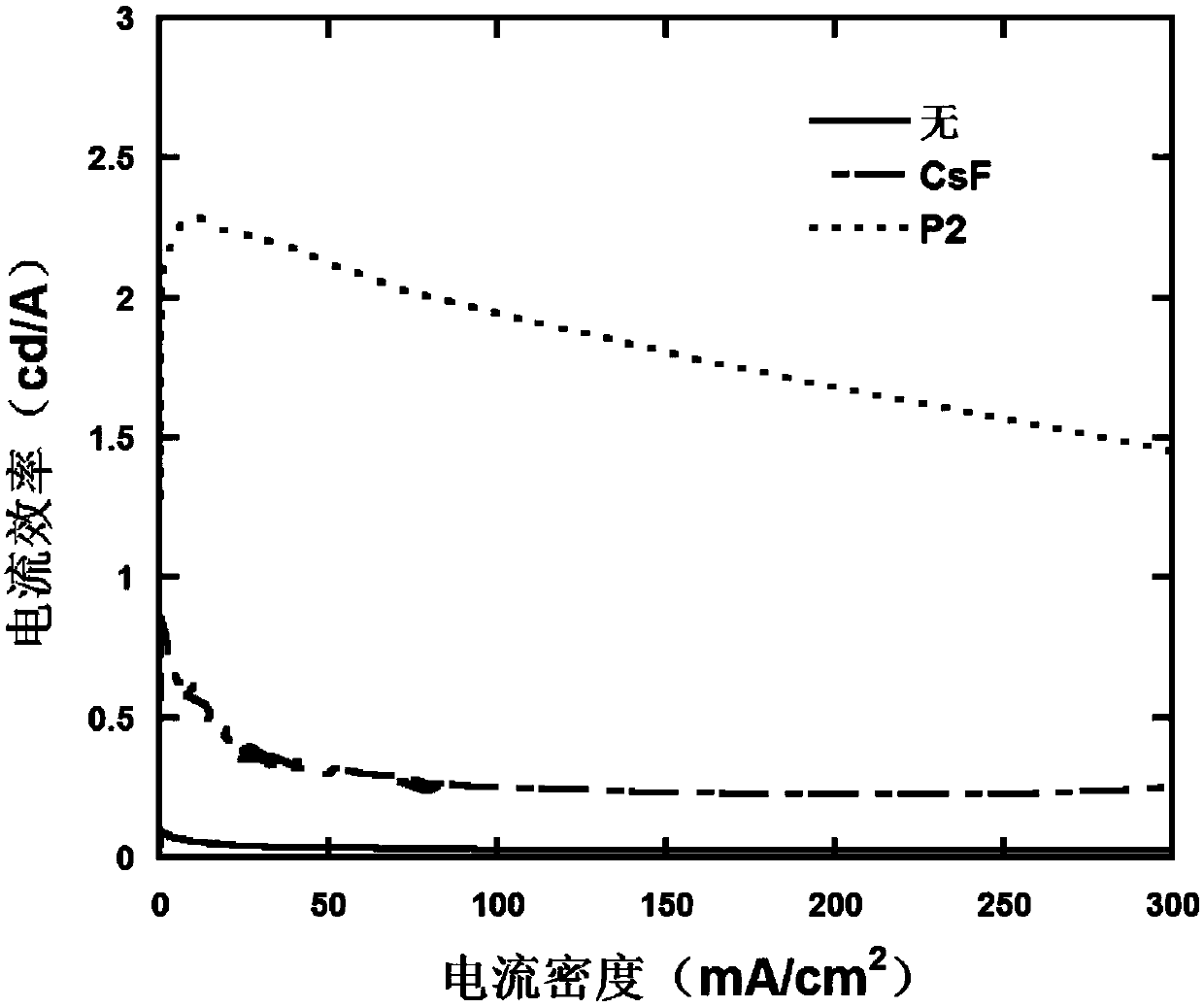

A polymer, alcohol-soluble technology, used in applications, semiconductor/solid-state device manufacturing, household appliances, etc., can solve the problems of high electron mobility, lower LUMO energy level, etc., achieve simple processing technology, improve electron injection and transmission capabilities , the effect of improving the exciton recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of compound 3

[0042] (1) Preparation of compound 1

[0043]Under nitrogen protection, 4-bromo-2-iodothiophenol (3.15g, 10mmol), palladium acetate (112mg, 0.5mmol), triphenylphosphine (0.26g, 0.5mmol), tert-butyl Sodium alkoxide (2.88g, 30mmol) and 80ml of anhydrous toluene were heated to 80°C and reacted for 24 hours; after the reaction liquid was cooled, the product was extracted with dichloromethane, and the organic phase was washed three times with saturated saline; the solvent was spin-dried, and the crude product was used Petroleum ether was used as the eluent for column chromatography to obtain 3.18 g of a white solid with a yield of 85%. 1 HNMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product.

[0044] (2) Preparation of compound 2

[0045] Under nitrogen protection, compound 1 (3.73g, 10mmol) and 150ml of anhydrous tetrahydrofuran were added to a 300ml two-neck flask, cooled to -78°C, a...

Embodiment 2

[0053] Preparation of compound M1

[0054] Under the protection of nitrogen, add compound 4 (7.08g, 10mmol), diethylamine (3.66g, 50mmol) and 100ml tetrahydrofuran into a 300ml two-necked flask, stir and heat to 70°C for 8 hours; cool the reaction solution, and dichloromethane The product was extracted, washed three times with water, and the solvent in the organic phase was removed by rotary evaporation to obtain a crude product, which was then recrystallized three times with a mixed solvent of ethanol / n-hexane to obtain 4.51 g of a white crystal product with a yield of 65%. 1 H NMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product. The chemical reaction equation is as follows:

[0055]

Embodiment 3

[0057] Preparation of compound M2

[0058] Under nitrogen protection, compound 4 (7.08g, 10mmol), diethanolamine (5.26g, 50mmol) and 70ml N,N-dimethylformamide were added to a 150ml two-necked flask, heated to 65°C for 8 hours; The product was extracted with methyl chloride, washed three times with water, and the solvent in the organic phase was removed by rotary evaporation to obtain a crude product, which was recrystallized three times with a mixed solvent of ethanol / n-hexane to obtain 5.36 g of a white powder product with a yield of 71%. 1 H NMR, 13 The results of CNMR, MS and elemental analysis showed that the obtained compound was the target product. The chemical reaction equation is as follows:

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com