Preparation method of carboxymethylcellulose porous hemostatic microspheres

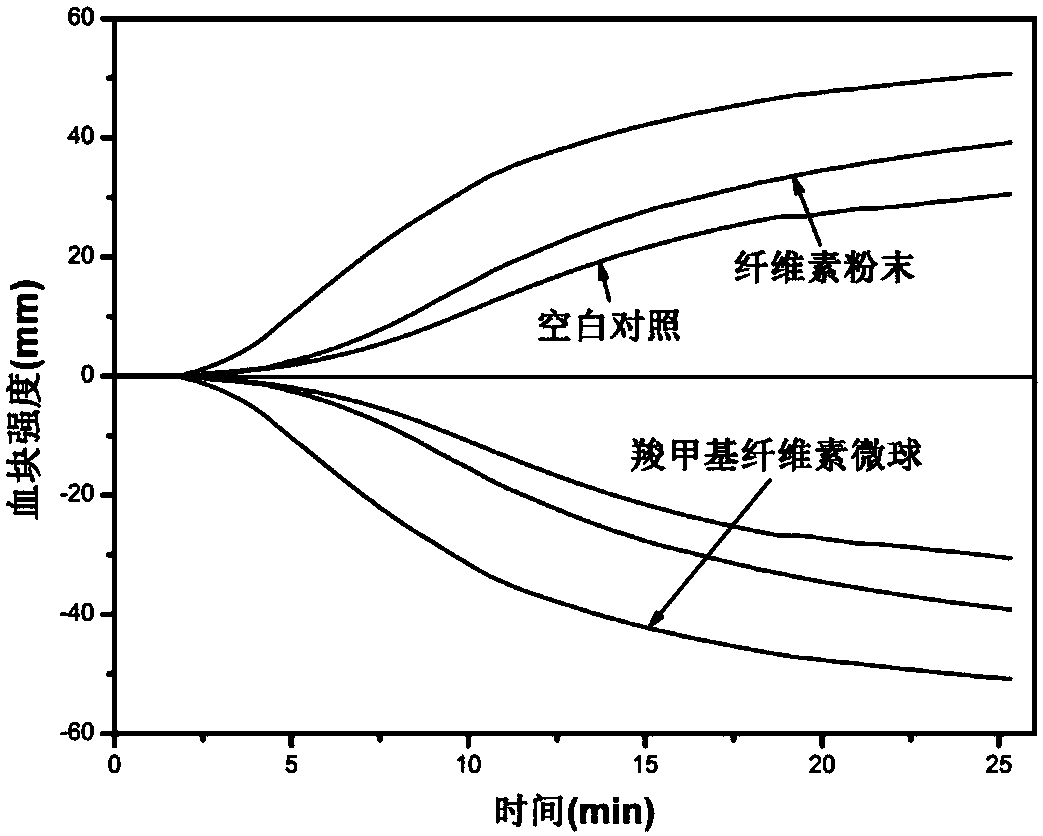

A technology of carboxymethyl cellulose and cellulose, which is applied in the field of preparation of carboxymethyl cellulose porous hemostatic microspheres, can solve the problems of long preparation time, high cost, environmental pollution, etc., and achieve fast preparation speed and uniform particle size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of 3.85% cellulose solution: Dissolve 7g of lithium hydroxide and 12g of urea in 81g of water, then add 4g of cellulose into the solvent, and stir at room temperature for 15min. Put the mixed solution in a low-temperature refrigerator to freeze at -30°C, take it out and thaw while stirring, and then refrigerate at 4°C for 1 day. Then take it out and stir evenly, then filter it with a 400-mesh filter cloth, and let the filtrate stand at 4°C for 3 hours.

[0028] 2. Preparation of carboxymethyl cellulose solution: add 0.2 g of sodium chloroacetate to 25 g of 4% cellulose solution, and stir magnetically at 8° C. for 24 hours. The carboxymethyl substitution degree of carboxymethyl cellulose is 0.07.

[0029] 3. Prepare coagulation solution: Dissolve 20mL sulfuric acid in 230mL aqueous solution as coagulation solution.

[0030] 4. Preparation of microspheres: inject 25 g of carboxymethyl cellulose solution into a 20 mL syringe, and obtain carboxymethyl cellu...

Embodiment 2

[0034] 1. Preparation of 3.85% cellulose solution: Dissolve 7g of lithium hydroxide and 12g of urea in 81g of water, then add 4g of cellulose into the solvent, and stir at room temperature for 15min. Put the mixed solution in a low-temperature refrigerator to freeze at -30°C, take it out and thaw while stirring, and then refrigerate at 4°C for 1 day. Then take it out and stir evenly, then filter it with a 400-mesh filter cloth, and let the filtrate stand at 4°C for 3 hours.

[0035] 2. Preparation of carboxymethyl cellulose solution: add 1 g of sodium chloroacetate to 25 g of 4% cellulose solution, and stir magnetically at 8°C for 24 hours. The carboxymethyl substitution degree of carboxymethyl cellulose is 0.13.

[0036] 3. Prepare coagulation solution: Dissolve 20mL sulfuric acid in 230mL aqueous solution as coagulation solution.

[0037] 4. Preparation of microspheres: inject 25 g of carboxymethyl cellulose solution into a 20 mL syringe, and obtain carboxymethyl cellulose...

Embodiment 3

[0040] 1. Preparation of 3.85% cellulose solution: Dissolve 7g of lithium hydroxide and 12g of urea in 81g of water, then add 4g of cellulose into the solvent, and stir at room temperature for 15min. Put the mixed solution in a low-temperature refrigerator to freeze at -30°C, take it out and thaw while stirring, and then refrigerate at 4°C for 1 day. Then take it out and stir evenly, then filter it with a 400-mesh filter cloth, and let the filtrate stand at 4°C for 3 hours.

[0041] 2. Preparation of carboxymethyl cellulose solution: add 0.1 g of sodium chloroacetate to 25 g of 4% cellulose solution, and stir magnetically at 8° C. for 24 hours. The carboxymethyl substitution degree of carboxymethyl cellulose is 0.02.

[0042] 3. Prepare coagulation solution: Dissolve 20mL sulfuric acid in 230mL aqueous solution as coagulation solution.

[0043] 4. Preparation of microspheres: inject 25 g of carboxymethyl cellulose solution into a 20 mL syringe, and obtain carboxymethyl cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com