A kind of preparation method of toughening and drag-reducing carbon fiber composite material

A technology of composite materials and carbon fibers, which is applied in the field of preparation of carbon fiber composite materials toughened by nano-hybrid fiber membranes, can solve the problems of insufficient intrinsic brittle electrical conductivity, achieve good electron conduction rate, improve damage resistance, reduce The effect of filler dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

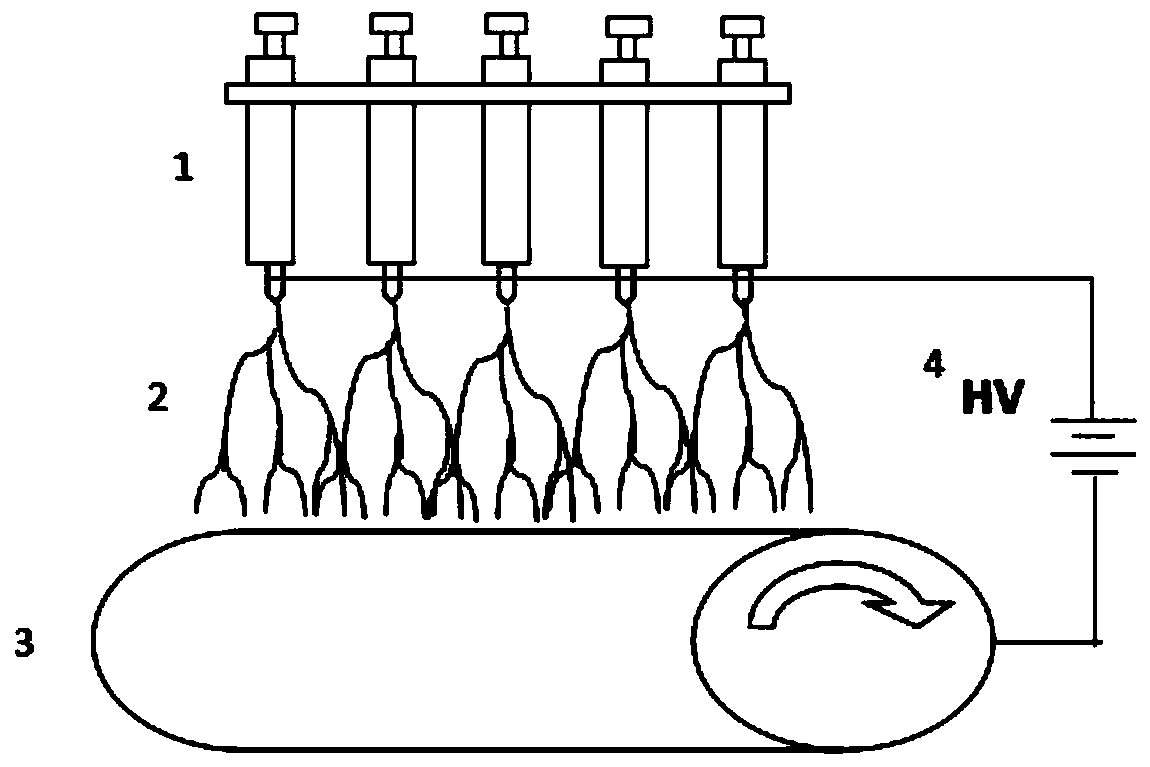

Method used

Image

Examples

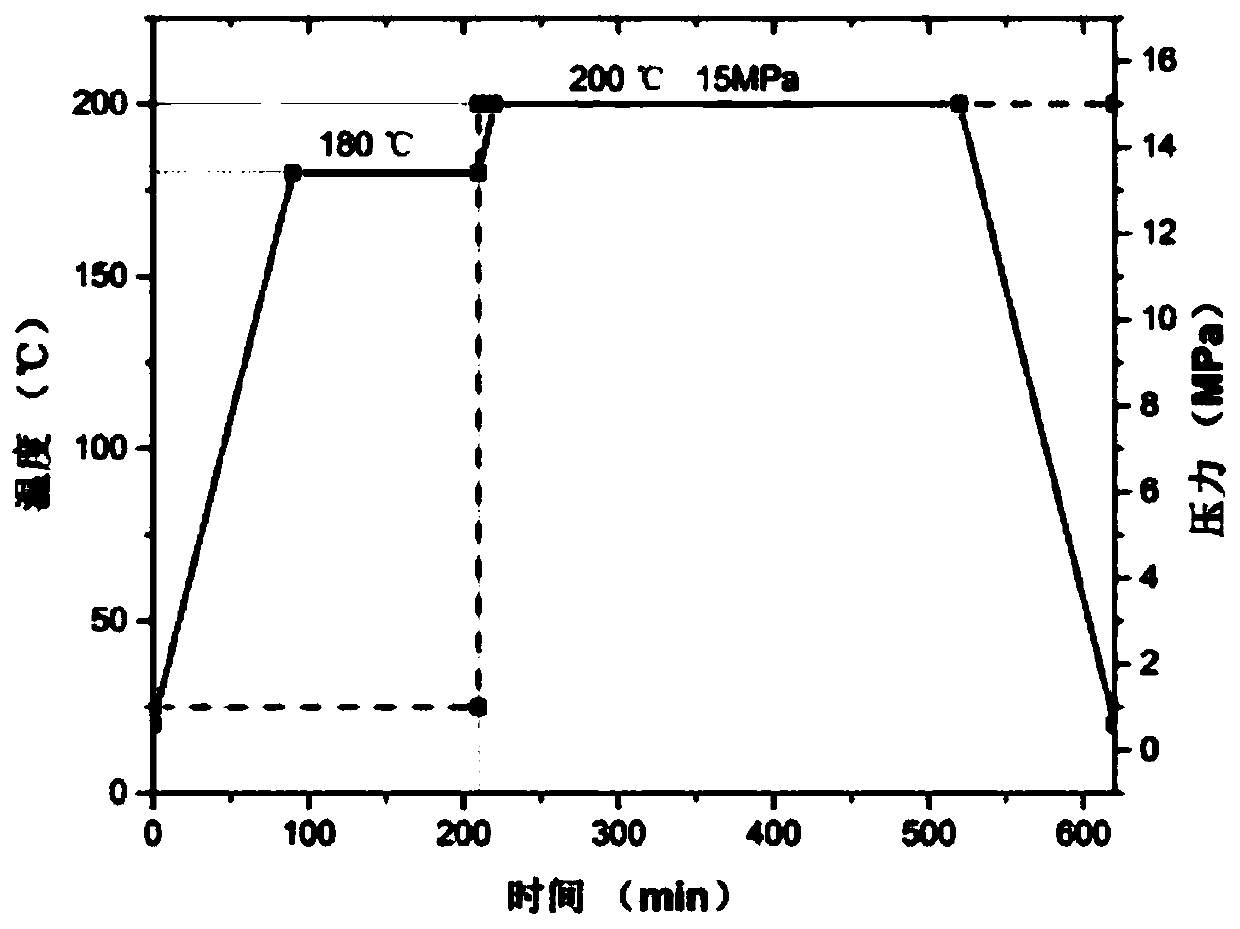

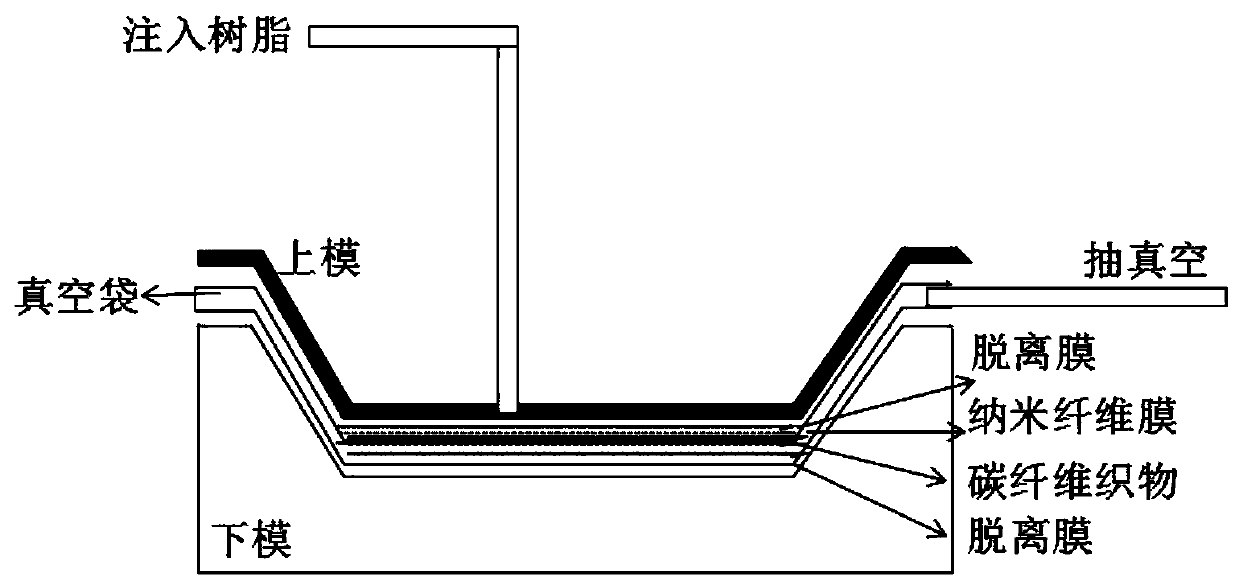

Embodiment 1

[0041] Weigh 0.09g of graphene microflakes, disperse them in N,N-dimethylformamide, ultrasonicate for 1h, and the ultrasonic power is 200W, to obtain a uniform and stable graphene suspension; weigh 0.54g of carbon nanotube dispersant Dissolve in N,N-dimethylformamide, then add 0.9g carbon nanotube (CNT) to make carbon nanotube suspension, stir ultrasonically, ultrasonic power 100~500W, ultrasonic dispersion time 1~3h, until it is in the container No black particle precipitation can be observed at the bottom stirrer; the graphene suspension and the carbon nanotube suspension are mixed evenly under ultrasonic and mechanical stirring, the ultrasonic power is 300w, and the ultrasonic stirring time is 1h to obtain a composite filler suspension. Standing at room temperature for a week did not cause delamination. 9g of nylon 12 (PA12) powder was dissolved in N,N-dimethylformamide solvent, and the composite filler suspension was uniformly mixed with the homogeneously dissolved nylon 1...

Embodiment 2

[0043] Weigh 0.09g of graphene microflakes, disperse them in N,N-dimethylformamide, ultrasonicate for 1h, and the ultrasonic power is 200W, to obtain a uniform and stable graphene suspension; weigh 0.54g of carbon nanotube dispersant Dissolve in N,N-dimethylformamide, then add 0.9g carbon nanotube (CNT) to make carbon nanotube suspension, stir ultrasonically, ultrasonic power 100~500W, ultrasonic dispersion time 1~3h, until it is in the container No black particle precipitation can be observed at the bottom stirrer; the graphene suspension and the carbon nanotube suspension are mixed evenly under ultrasonic and mechanical stirring, the ultrasonic power is 300w, and the ultrasonic stirring time is 1h to obtain a composite filler suspension. Standing at room temperature for a week did not cause delamination. Dissolve 9g of thermoplastic polyurethane (TPU) powder in N,N-dimethylformamide solvent, mix the composite filler suspension with the homogeneously dissolved thermoplastic p...

Embodiment 3

[0045] Weigh 0.09g of graphene microflakes, disperse them in a mixed solvent of N,N-dimethylformamide and tetrahydrofuran, ultrasonicate for 1h, and the ultrasonic power is 200W, to obtain a uniform and stable graphene suspension; weigh 0.54g of carbon The nanotube dispersant is pre-dissolved in a mixed solvent of N,N-dimethylformamide and tetrahydrofuran, and then 0.9g of carbon nanotubes (CNT) is added to form a carbon nanotube suspension, stirred ultrasonically, and the ultrasonic power is 100-500W. Ultrasonic dispersion time is 1 to 3 hours, until no black particle precipitation is observed at the stirring bar at the bottom of the container; the graphene suspension and carbon nanotube suspension are mixed evenly under ultrasonic and mechanical stirring, the ultrasonic power is 300w, and the ultrasonic stirring time is 1h , to obtain a composite filler suspension, the suspension was left standing at room temperature for a week without delamination. Dissolve 9g of thermoplas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com