Special steel bar embedding adhesive for steel bar and concrete anchoring

A technology for concrete and reinforcing bar glue, applied in the direction of adhesive type, adhesive additive, non-polymer adhesive additive, etc., can solve the problems of poor mechanical properties and water resistance of reinforcing bar glue, and enhance mechanical properties , Improve water resistance, enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

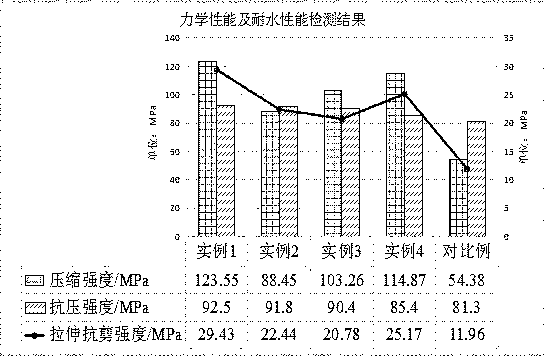

Examples

example 1

[0027]Add polyvinyl alcohol and 3% acetic acid solution with a mass fraction of 1:100 into a beaker, stir and mix with a glass rod for 30 minutes, then let it stand for swelling for 4 hours to obtain a swelling solution, then add the swelling solution into a three-necked flask, and then Move the three-neck flask into a magnetic stirrer with digital display speed measurement and constant temperature, and stir and dissolve for 40 minutes at a temperature of 100°C and a rotation speed of 500r / min to obtain a solution; put beeswax 0.2 times the mass of polyvinyl alcohol into a crucible, Melt at 80°C for 30 minutes to obtain liquid beeswax, then add all the obtained liquid beeswax to the solution, stir and mix for 40 minutes at a temperature of 100°C and a rotating speed of 500r / min, and then use a constant pressure dropping funnel at 2.5 Add 0.2 times the mass of polyvinyl alcohol Tween-60 dropwise to a three-necked flask at a rate of mL / min, and stir and emulsify for 40 minutes at...

example 2

[0029] Add polyvinyl alcohol and 3% acetic acid solution with a mass fraction of 1:100 into a beaker, stir and mix with a glass rod for 30 minutes, then let it stand for swelling for 4 hours to obtain a swelling solution, then add the swelling solution into a three-necked flask, and then Move the three-neck flask into a magnetic stirrer with digital display speed measurement and constant temperature, and stir and dissolve for 40 minutes at a temperature of 100°C and a rotation speed of 500r / min to obtain a solution; put beeswax 0.2 times the mass of polyvinyl alcohol into a crucible, Melt at 80°C for 30 minutes to obtain liquid beeswax, then add all the obtained liquid beeswax to the solution, stir and mix for 40 minutes at a temperature of 100°C and a rotating speed of 500r / min, and then use a constant pressure dropping funnel at 2.5 Add 0.2 times the mass of polyvinyl alcohol Tween-60 dropwise to a three-necked flask at a rate of mL / min, and stir and emulsify for 40 minutes a...

example 3

[0031] Add polyvinyl alcohol and 3% acetic acid solution with a mass fraction of 1:100 into a beaker, stir and mix with a glass rod for 30 minutes, then let it stand for swelling for 4 hours to obtain a swelling solution, then add the swelling solution into a three-necked flask, and then Move the three-neck flask into a magnetic stirrer with digital display speed measurement and constant temperature, and stir and dissolve for 40 minutes at a temperature of 100°C and a rotation speed of 500r / min to obtain a solution; put beeswax 0.2 times the mass of polyvinyl alcohol into a crucible, Melt at 80°C for 30 minutes to obtain liquid beeswax, then add all the obtained liquid beeswax to the solution, stir and mix for 40 minutes at a temperature of 100°C and a rotating speed of 500r / min, and then use a constant pressure dropping funnel at 2.5 Add 0.2 times the mass of polyvinyl alcohol Tween-60 dropwise to a three-necked flask at a rate of mL / min, and stir and emulsify for 40 minutes a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap