Preparation method and application of homogenous barrier layer/frame titanium dioxide structure

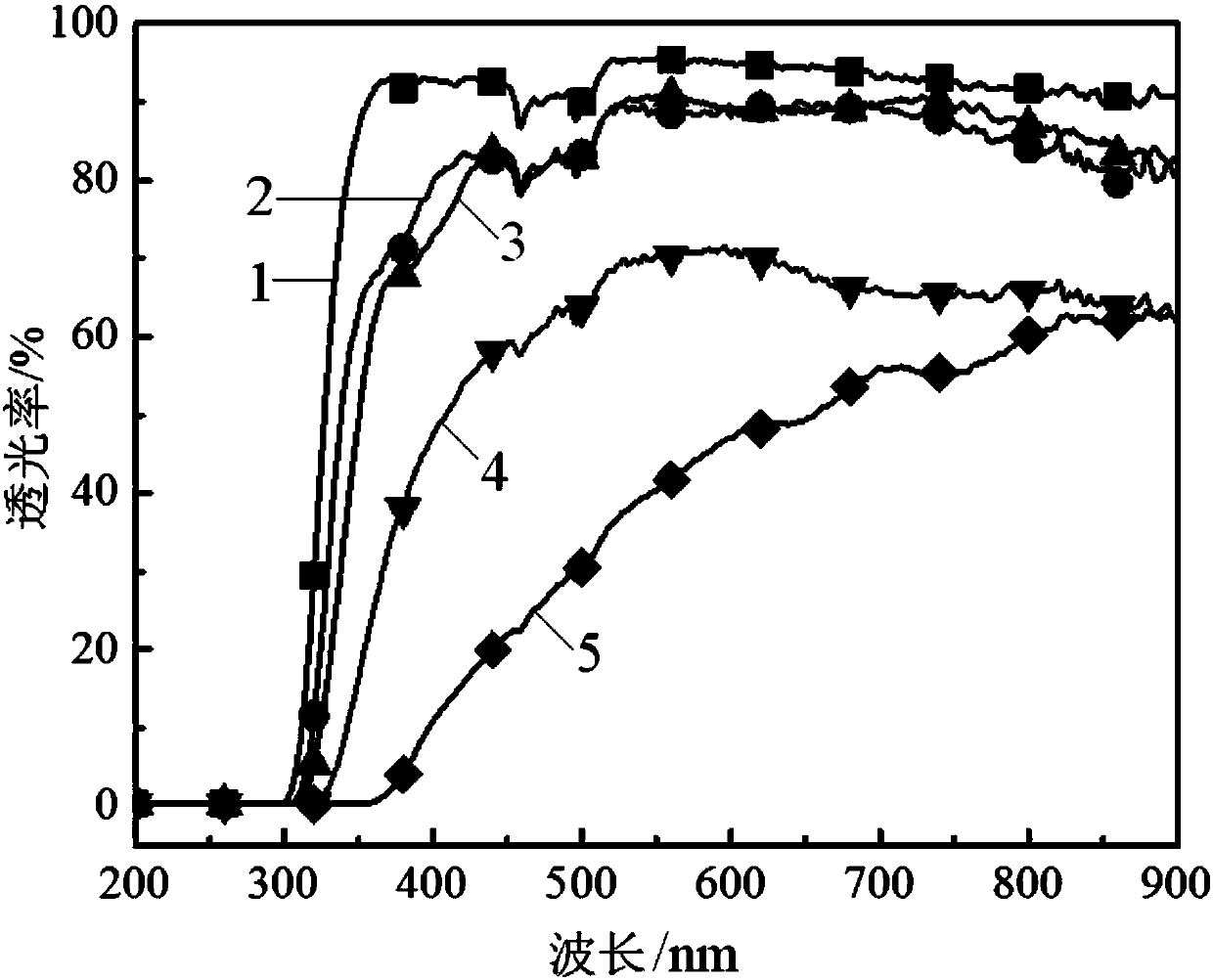

A technology of titanium dioxide and barrier layer is applied in the field of photoanode preparation, which can solve the problems of low electron transmission efficiency and easy recombination of photoelectrons, and achieve the effects of shortening electron transmission distance, avoiding grain boundary charge transfer resistance and improving transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

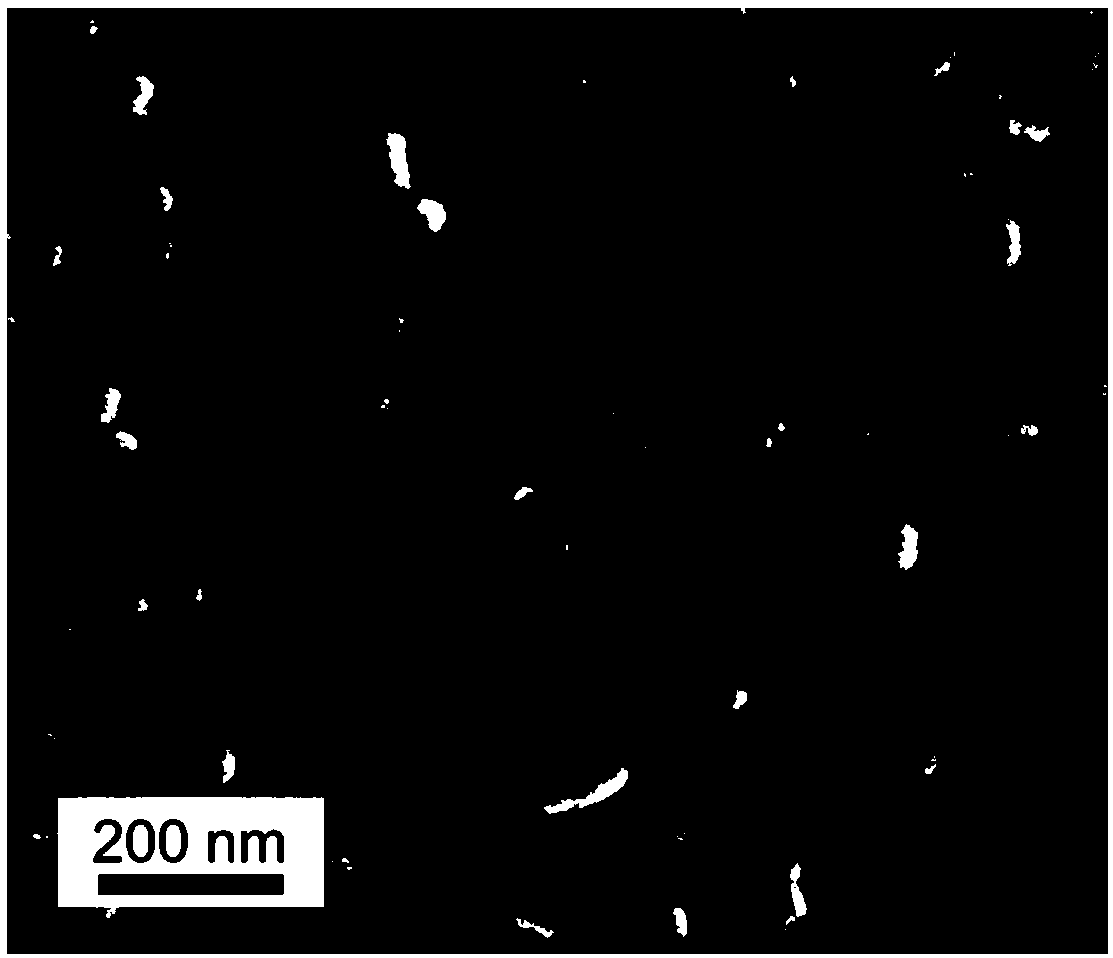

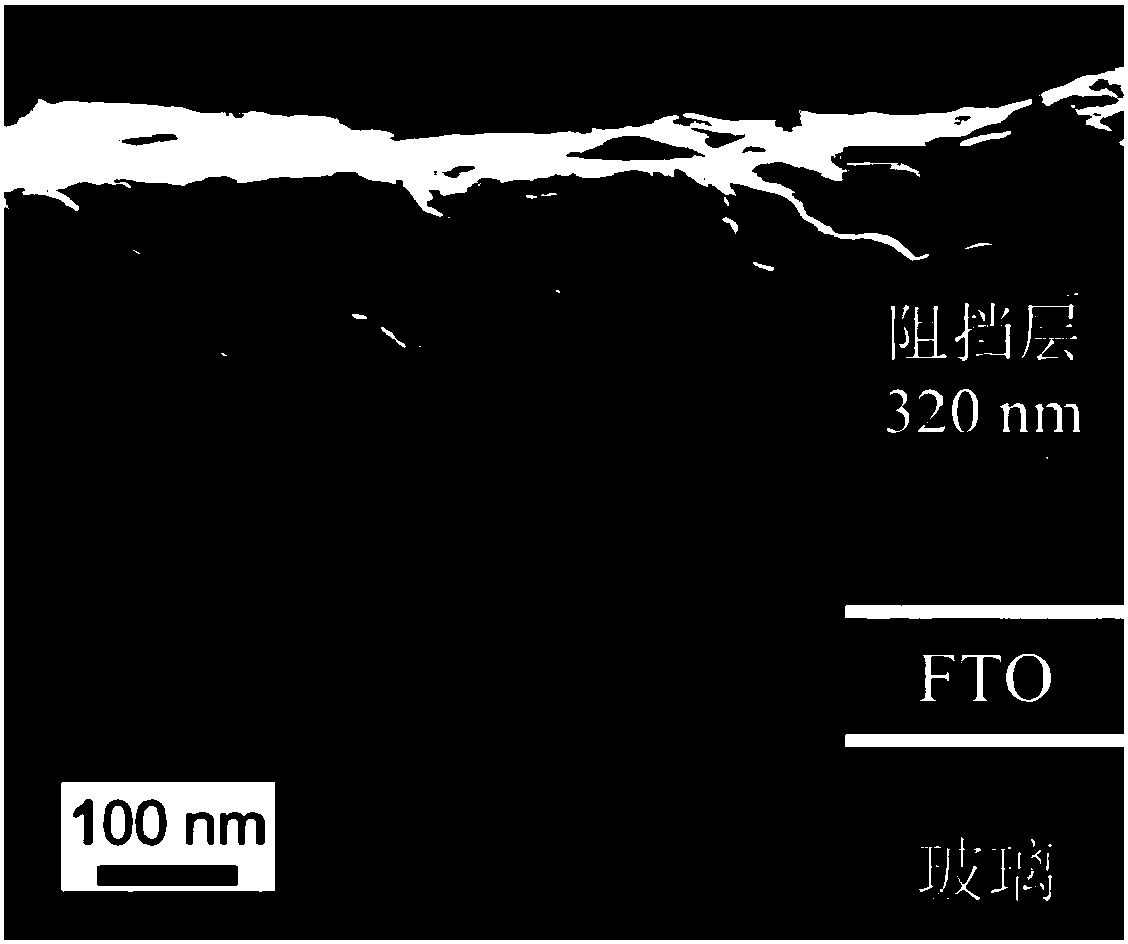

[0036] Specific implementation mode 1: This implementation mode is a preparation method of a homogeneous barrier layer / skeleton titanium dioxide structure, which is specifically completed according to the following steps:

[0037] 1. The conductive substrate is ultrasonically cleaned in toluene, acetone, absolute ethanol and deionized water in sequence, then rinsed with absolute ethanol for 2 to 4 times, and finally dried with nitrogen to obtain a conductive substrate with impurities removed;

[0038] 2. Preparation of barrier layer reaction solution:

[0039] 1. Adding hydrochloric acid with a mass fraction of 32% to 35% into distilled water, stirring evenly, to obtain a hydrochloric acid solution;

[0040] The mass fraction described in step 2 ① is that the volume ratio of hydrochloric acid and distilled water of 32%~35% is (0.5~2.3):1;

[0041] ②. Heat the hydrochloric acid solution obtained in step 2 ① to 40°C-70°C, then add tetrabutyl titanate dropwise at a temperature o...

specific Embodiment approach 2

[0059] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the conductive substrate described in step 1 is FTO conductive glass, ITO conductive glass or flexible graphene substrate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0060] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the frequency of ultrasonic cleaning of the conductive substrate in toluene is 30 kHz to 90 kHz, the time of ultrasonic cleaning is 15 min to 60 min, and the conductive substrate is cleaned in acetone The frequency of ultrasonic cleaning in the medium is 30kHz~90kHz, and the time of ultrasonic cleaning is 15min~60min. The frequency of ultrasonic cleaning is 30kHz-90kHz, and the time of ultrasonic cleaning is 15min-60min. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com