A kind of hierarchical porous silicon aluminum molecular sieve nanocluster and its preparation method

A silica-alumina molecular sieve and multi-level pore technology, applied in nanotechnology, crystalline aluminosilicate zeolite, etc., can solve the problems of limited application, nano-molecular sieve agglomeration and separation process, complexity, etc., to improve selectivity and improve anti-carbon deposition. ability, the effect of improving the diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

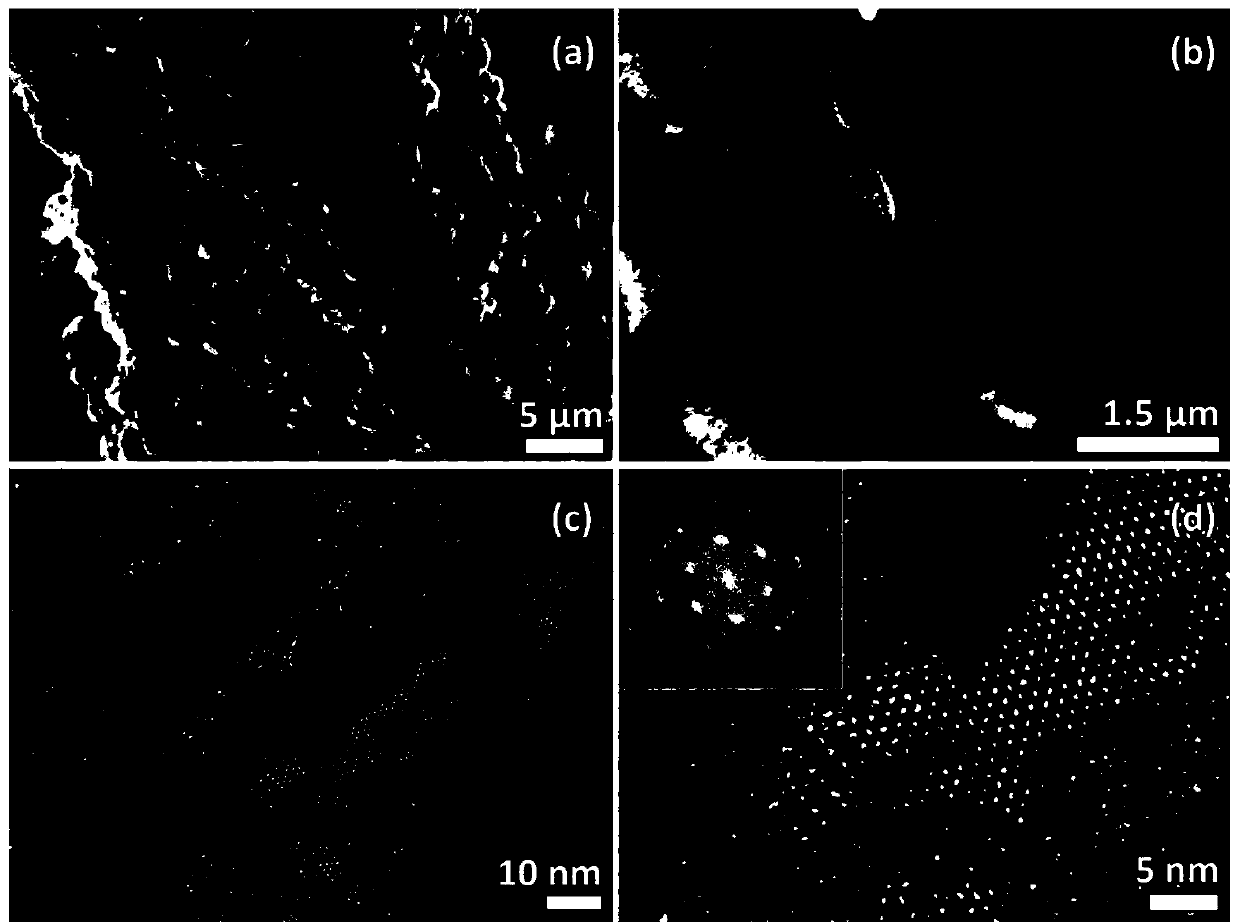

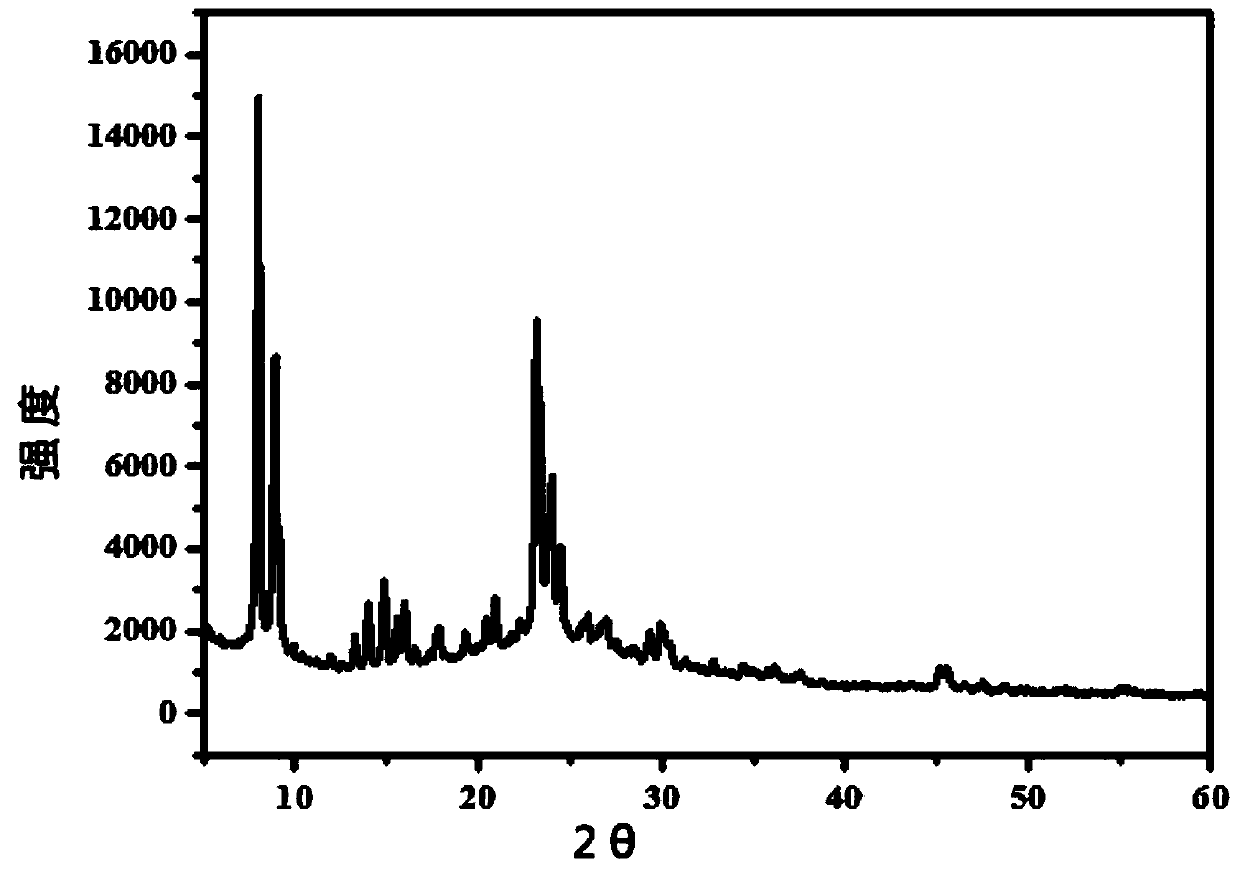

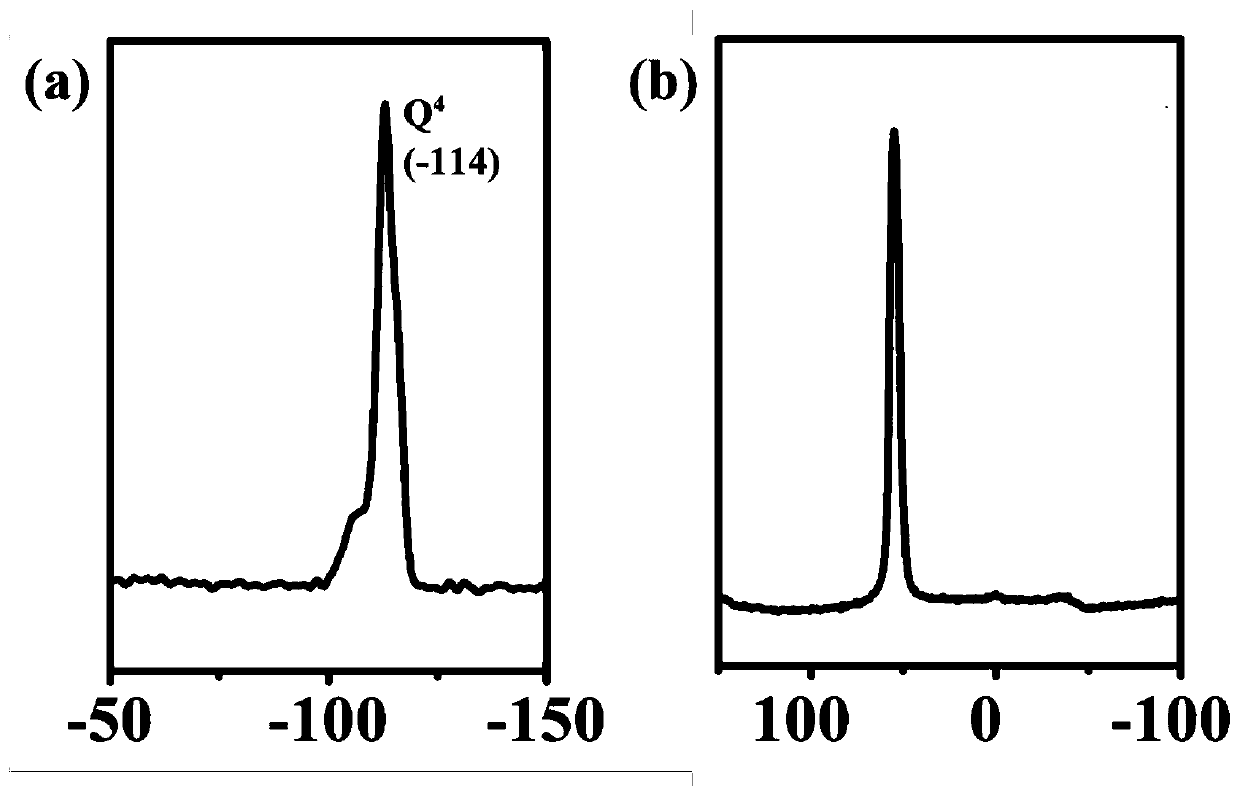

[0028] A nano-cluster of hierarchically porous silicon-alumina molecular sieves, the molar ratio of silicon source, aluminum source, and structure-directing agent in the preparation process is 1:0.01:0.36, and the SiO obtained after the silicon source is hydrolyzed 2 Accounting for 3% of the mass of the ordered macroporous-mesoporous hierarchically porous carbon material, it specifically includes the following steps:

[0029] Add 329 μL of TEOS and 0.00612 g of aluminum isopropoxide into a mixed solution of 1.218 g of tetrapropylammonium hydroxide aqueous solution (20 wt.%), 1.35 g of deionized water and 0.345 g of ethanol (National Medicine), stir well for 5 hours, and then add 3g of ordered macroporous-mesoporous hierarchical carbon material (macropore diameter is 400nm, mesopore diameter is 20nm) to obtain mixed solution I, dried and aged in an oven at 40°C for 10h to obtain dry glue; put the obtained dry glue in 150mL In the reaction kettle, take 0.2g of deionized water fr...

Embodiment 2

[0032] A nano-cluster of hierarchically porous silicon-alumina molecular sieves, the molar ratio of silicon source, aluminum source, and structure-directing agent in the preparation process is 1:0.001:0.5, and the SiO obtained after the silicon source is hydrolyzed 2 Accounting for 5% of the mass of the ordered macroporous-mesoporous hierarchical porous carbon material, it specifically includes the following steps:

[0033] Add 548μL of TEOS and 0.00051g of aluminum isopropoxide into a mixed solution of 1.2688g of tetrapropylammonium hydroxide aqueous solution (20wt.%), 2.25g of deionized water and 4.6g of ethanol (National Medicine), and stir well for 5 hours before adding 3g of ordered macroporous-mesoporous hierarchical carbon material (macropore diameter is 400nm, mesopore diameter is 20nm) to obtain mixed solution I, dried and aged in an oven at 40°C for 10h to obtain dry glue; put the obtained dry glue in 100mL In the reaction kettle, take 0.2g of deionized water from th...

Embodiment 3

[0036] A kind of hierarchical porous silicon aluminum molecular sieve nanocluster, the molar ratio of silicon source, aluminum source and structure directing agent in the preparation process is 1:0.005:0.65, the SiO obtained after the silicon source is hydrolyzed 2 Accounting for 10% of the mass of the ordered macroporous-mesoporous hierarchically porous carbon material, it specifically includes the following steps:

[0037] Add 1095μL TEOS and 0.0051g aluminum isopropoxide to the mixed solution of 3.2988g tetrapropylammonium hydroxide aqueous solution (20wt.%), 4.5g deionized water and 4.6g ethanol (National Medicine), stir well for 5 hours and then add 3g of ordered macroporous-mesoporous hierarchical carbon material (macropore diameter is 400nm, mesopore diameter is 20nm) to obtain mixed solution I, dried and aged in an oven at 40°C for 10h to obtain dry glue; put the obtained dry glue in 150mL In the reaction kettle, take 0.2g of deionized water from the bottom of the kett...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com