Equipment for production of carbon nanotubes with fluidized bed and preparation method thereof

A technology of carbon nanotubes and fluidized beds, applied in the direction of carbon nanotubes, chemical instruments and methods, and nanocarbons, can solve the problems of complex fixed bed production equipment, high energy consumption, and low production efficiency, and achieve high operational flexibility , low energy consumption, and the effect of providing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

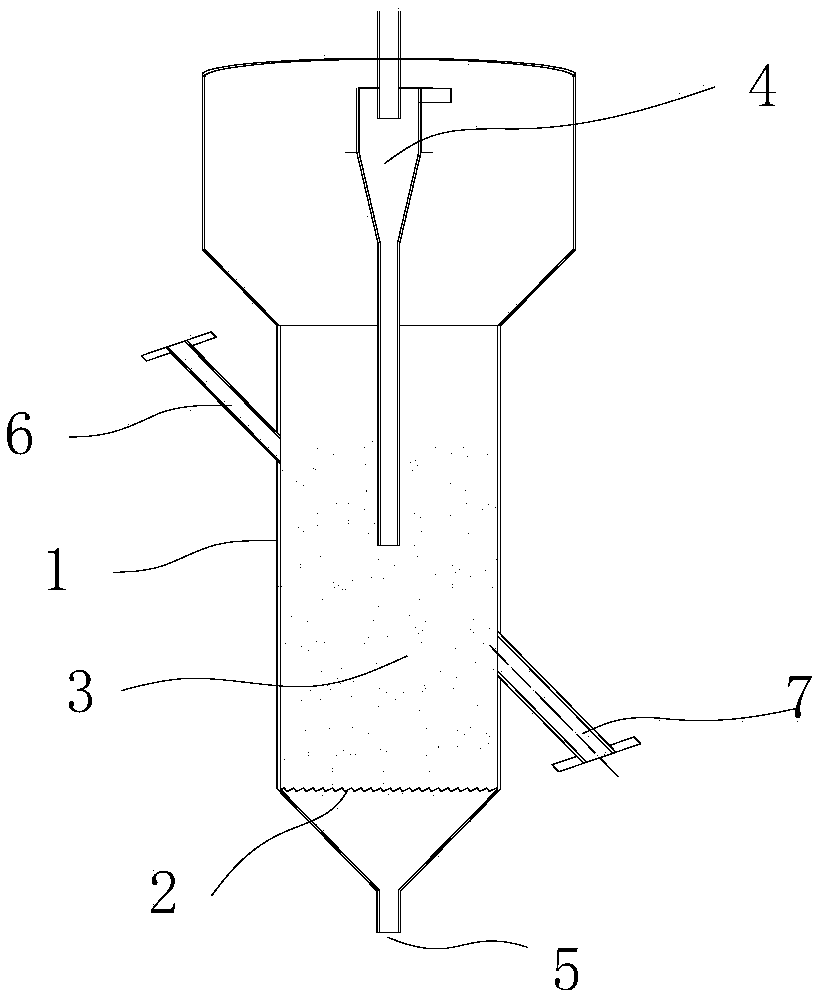

[0018] An apparatus for producing carbon nanotubes in a fluidized bed, such as figure 1 Shown, comprise main reaction furnace 1, gas distributor 2, fluidized bed 3 and gas-solid separator 4, fluidized bed 3 is positioned at the middle and lower part of main reaction furnace 1, and gas-solid separator 4 is positioned at the top of main reaction furnace 1, The bottom end of the gas-solid separator 4 is inserted into the fluidized bed 3 and the top of the gas-solid separator 4 is directly discharged from the top of the main reaction furnace 1; the bottom of the main reaction furnace 1 is provided with a carbon source gas inlet 5, and a gas distributor 4 It is arranged on the upper side of the carbon source gas inlet 5 and installed on the cross section of the main reaction furnace 1 at the bottom of the fluidized bed 3; A catalyst inlet 6 for adding catalyst, and a carbon nanotube outlet 7 for continuously generating carbon nanotubes are provided at the obliquely downward positio...

Embodiment 2

[0023] The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here; the difference is that the control parameters selected in this embodiment are different from those of Embodiment 1, as follows:

[0024] The corresponding preparation method of producing carbon nanotubes with a fluidized bed of this embodiment comprises the following steps:

[0025] Electric heating is used to control the temperature of the fluidized bed to 750°C, and ethylene gas is introduced from the carbon source gas inlet at the bottom of the main reaction furnace, and the superficial velocity of the gas is controlled to be 20 cm / s; at the same time, according to the carbon element in the gas Add metal oxide catalysts such as iron, cobalt and nickel continuously in an amount of about 1%.

[0026] Fluidize and react in the fluidized bed, and generate carbon nanotubes with a diameter of 4-80 nanometers and a length of 0.5-200 microns, which are continuously discharged...

Embodiment 3

[0029] The structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here; the difference is that the materials and control parameters selected in this embodiment are different from those of Embodiment 1, as follows:

[0030] The corresponding preparation method of producing carbon nanotubes with a fluidized bed of this embodiment comprises the following steps:

[0031] Use tail gas to burn in the jacket on the outer wall of the fluidized bed, control the temperature to 900°C, feed methane gas from the carbon source gas inlet at the bottom of the main reactor, and control the superficial velocity of the gas to 50 cm / s;

[0032] At the same time, iron, cobalt, nickel and other metal oxide catalysts are continuously added in an amount of about 1% of the carbon element in the gas. Fluidize and react in the fluidized bed, and generate carbon nanotubes with a diameter of 4-80 nanometers and a length of 0.5-200 microns, which are continuously dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com