Carbon fiber sizing agent and preparation method thereof, carbon fiber reinforced polypropylene composite material and preparation method of carbon fiber reinforced polypropylene composite material

A composite material, carbon fiber technology, applied in the direction of carbon fiber, fiber processing, textile and papermaking, etc., can solve the problems of limited interface performance and poor adhesion performance of small molecule silane coupling agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

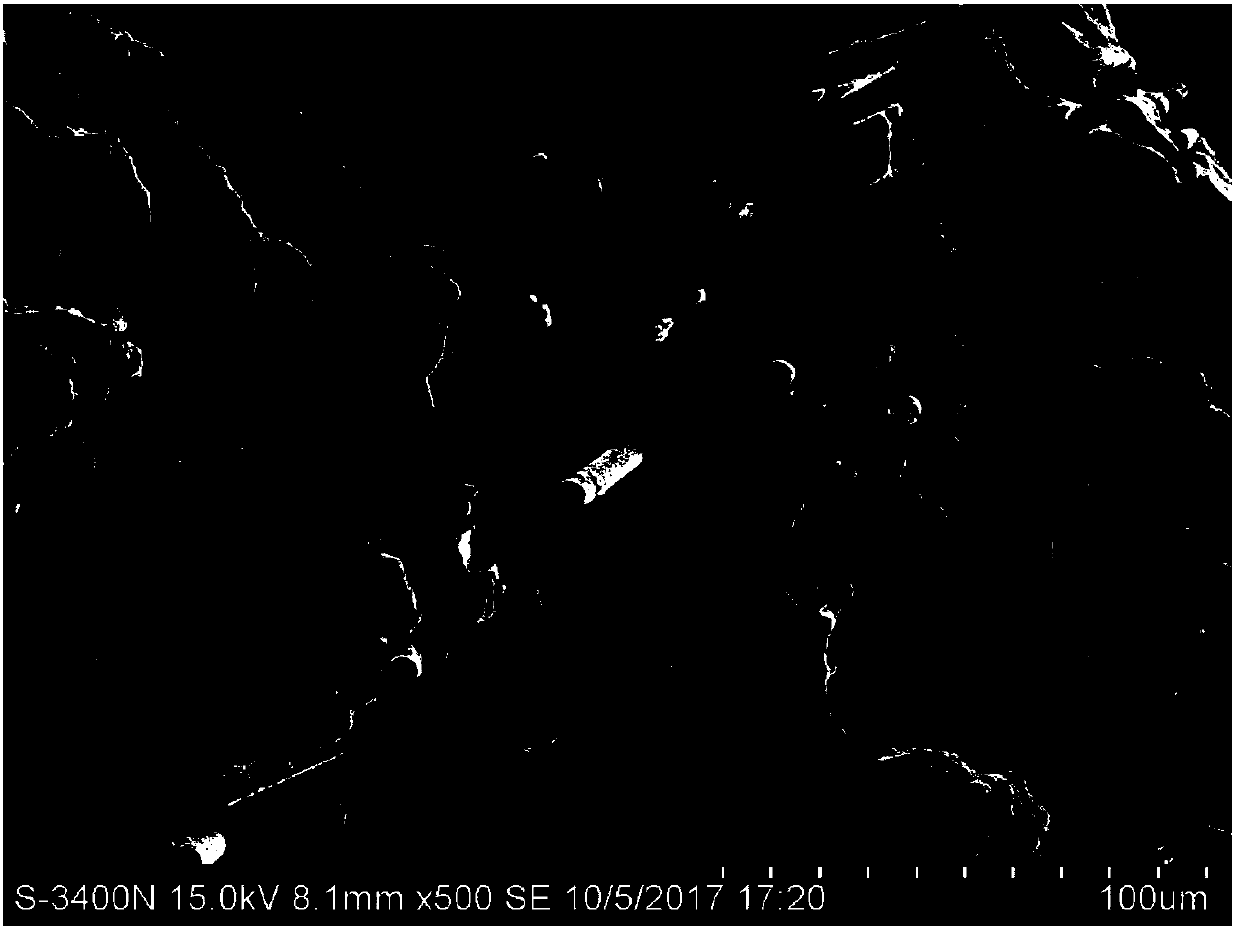

Image

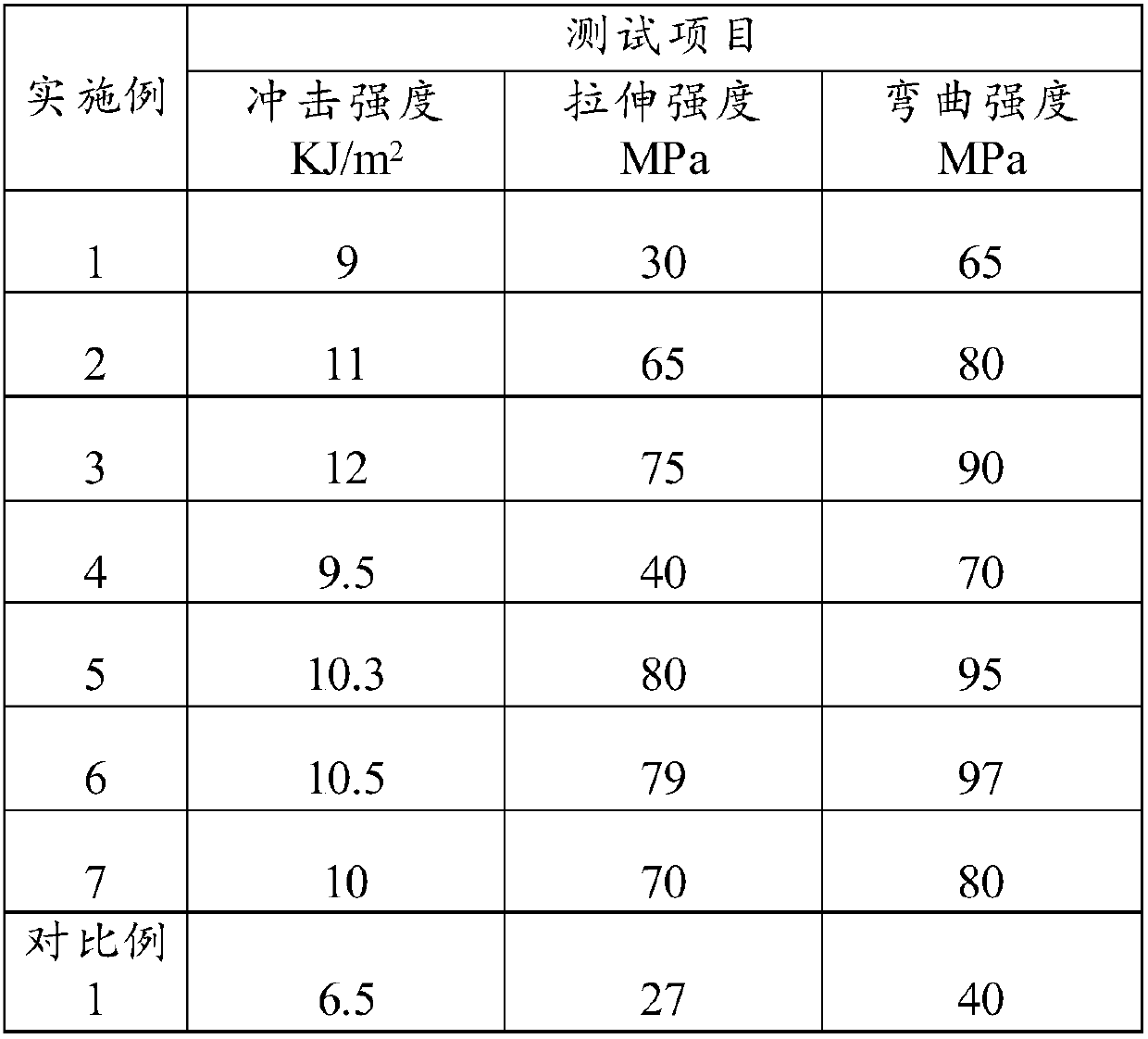

Examples

Embodiment 1

[0036] Preparation of sizing agent

[0037] (1) Under the condition of nitrogen protection and 30 DEG C, dodecene and maleic anhydride are dissolved in xylene according to the ratio of 1.0:1.0 substance amount;

[0038] (2) Add azobisisobutylcyanide, control the temperature at 80°C, stir at 200rpm, and react for 0.5 hours;

[0039] (3) Stir the solution with a high-speed shear dispersing emulsifier at a stirring speed of 500 rpm, add deionized water dropwise while stirring, continue stirring for 0.5 hours, and then spin evaporate the solution to remove acetone to obtain a polymer emulsion sizing agent.

[0040] Carbon fiber reinforced polypropylene composites were prepared as follows:

[0041] (4) Carbon fiber pretreatment: dip the carbon fiber in the sizing agent for 1 min at room temperature, and then dry it at 20° C. for 0.5 hour.

[0042] (5) Mixing: Add 100 parts of polypropylene, 3 parts of carbon fiber, 1010:0.1 part of antioxidant, and 1 part of chlorinated polyethyl...

Embodiment 2

[0046] Preparation of sizing agent

[0047] (1) Under nitrogen protection, under the condition of 30-70°C, dodecyne and maleic anhydride are dissolved in N, N dimethylformamide according to the ratio of substance amount of 1.0:2.0;

[0048] (2) Add benzoyl peroxide, control the temperature at 90°C, stir at 500rpm, and react for 3 hours;

[0049] (3) Stir the solution with a high-speed shear dispersing emulsifier at a stirring speed of 10,000 rpm, add deionized water dropwise while stirring, and continue stirring for 1.5 hours, then spin the solution to remove the organic solvent to obtain a polymer emulsion sizing agent.

[0050] Carbon fiber reinforced polypropylene composites were prepared as follows:

[0051] (4) Carbon fiber pretreatment: dip the carbon fiber in the sizing agent for 2 minutes at room temperature, and then dry it at 60°C for 40 minutes.

[0052] (5) Mixing: Add 100 parts of polypropylene, 11 parts of carbon fiber, 300:0.1 parts of antioxidant, and 5 parts...

Embodiment 3

[0057] Preparation of sizing agent

[0058] (1) under the condition of nitrogen protection and 50 DEG C, octadecene and maleic anhydride are dissolved in xylene according to the ratio of 1.0:0.8 substance amount;

[0059] (2) Add benzoyl peroxide, control the temperature at 90°C, stir at 600rpm, and react for 4 hours;

[0060] (3) Stir the solution with a high-speed shear dispersing emulsifier at a stirring speed of 3000 rpm, add deionized water dropwise while stirring, and continue stirring for 2 hours, then spin the solution to remove the organic solvent to obtain a polymer emulsion sizing agent.

[0061] Carbon fiber reinforced polypropylene composites were prepared as follows:

[0062] (4) Carbon fiber pretreatment: dip the carbon fiber in the sizing agent for 3 minutes at room temperature, and then dry it at 80°C for 1 hour.

[0063] (5) Mixing: Add 100 parts of polypropylene, 20 parts of carbon fiber, 1010:0.5 parts of antioxidant, and 2 parts of paraffin oil into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com