Sizing carbon fiber cloth reinforced flame-retardant epoxy resin and preparation method thereof

A technology of epoxy resin and carbon fiber cloth, which is applied in the field of polymer materials and can solve problems such as poor compatibility, easy moisture absorption, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation method of sizing agent reinforced carbon fiber cloth:

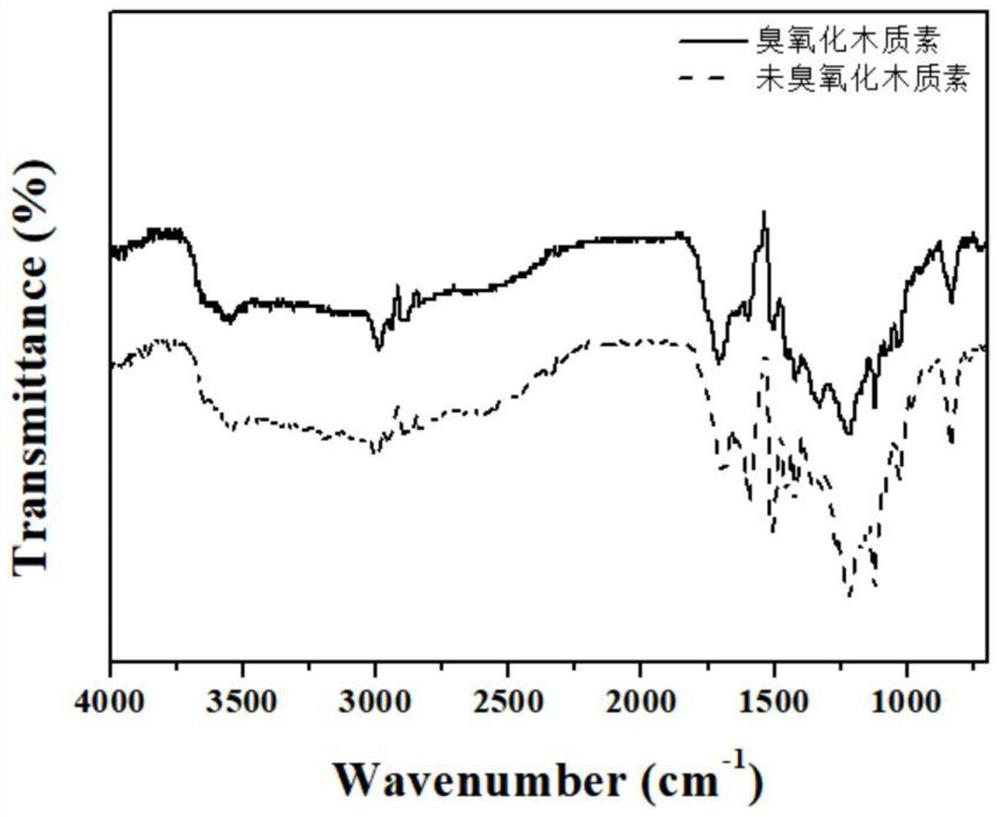

[0031] (1) Ozonation treatment of lignin: 5g of organic solvent lignin is placed in an ozonation device, and treated for 1.5h at a mixed gas flow rate of 450L / h and an ozone concentration of 13mg / L to obtain ozonated organic solvent lignin ;

[0032](2) After dissolving the organic solvent lignin and 8.5g bisphenol A type epoxy resin obtained by the ozonation treatment of 1.5g step (1) in N,N-dimethylformamide (DMF), stir at room temperature for 15 Minutes, then be warming up to 95 ℃ and stir to obtain lignin-based epoxy resin after 1.5 hours;

[0033] (3) Add absolute ethanol to the lignin-based epoxy resin obtained in step (2), then add 3g of diethanolamine, stir at 75°C for 2h, and stir at a speed of 400rpm to obtain a lignin-based ring grafted with diethanolamine oxygen resin;

[0034] (4) Add 1.75g of acetic acid solution to the lignin-based epoxy resin grafted with diethanolamine obtained in ...

Embodiment 2

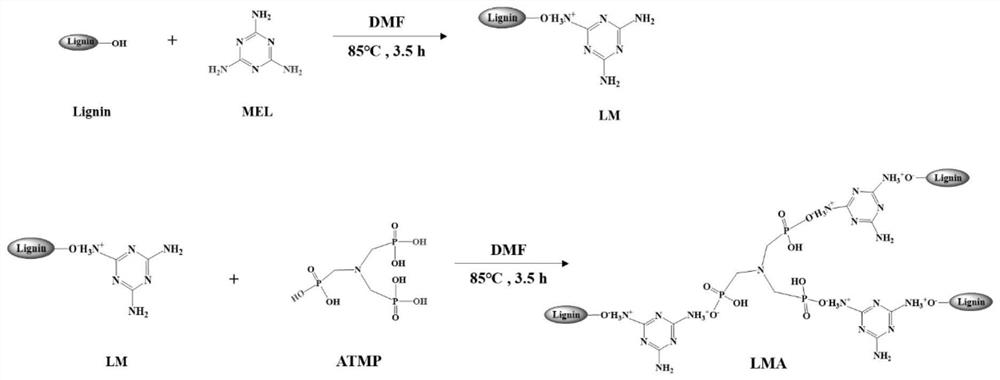

[0037] Preparation method of lignin-based intumescent flame retardant:

[0038] (1) Weigh 12.93g of enzymatic lignin (Lignin) and dissolve it in 20mL N,N-dimethylformamide (DMF), then add 12.60g of melamine (MEL) and mix well, heat to 80-100°C, and react 3 to 5 hours to obtain the intermediate product LM;

[0039] (2) Then add 29.90g of aminotrimethylene phosphonic acid (ATMP) to the intermediate product LM obtained in step (1), react at 80-100°C for 10-15 hours, ethanol elute to obtain the product lignin-based expansion type Flame retardant (LMA).

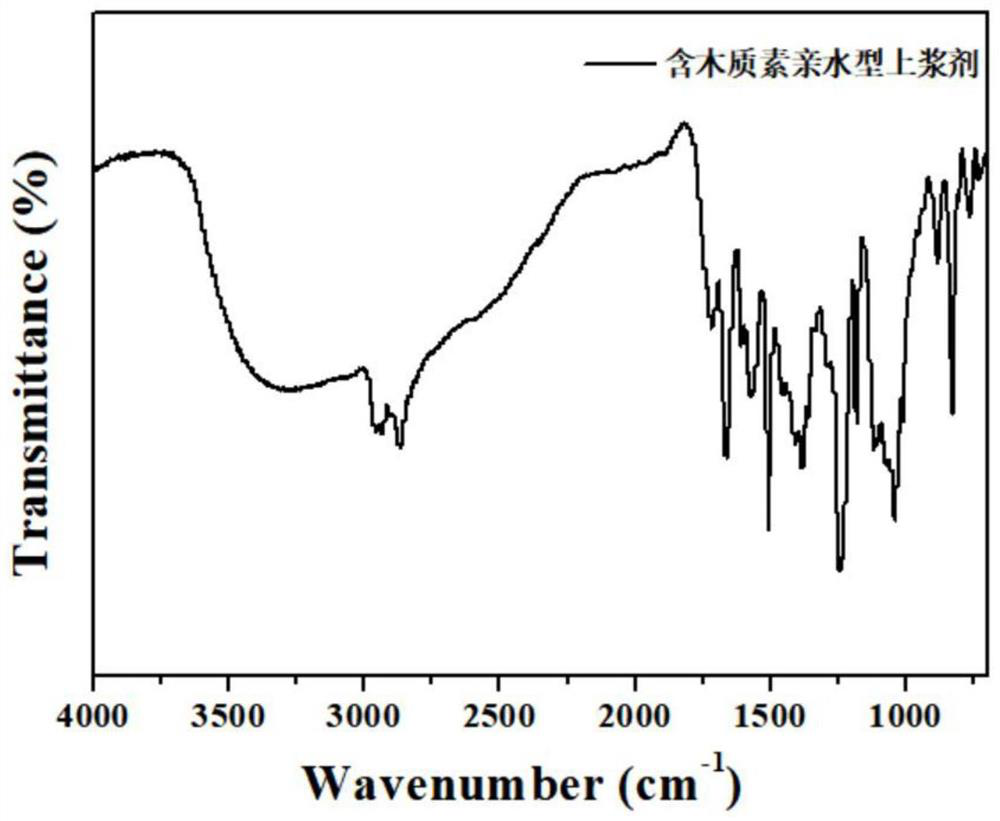

[0040] (3) The product LMA obtained in step (2) is dried at 70-80°C for 12-14 hours and then pulverized to obtain lignin-based intumescent flame retardant LMA powder. The synthesized lignin-based intumescent flame retardant Infrared characterization as Figure 4 shown.

Embodiment 3

[0042] The preparation method of the sizing carbon fiber cloth reinforced flame retardant epoxy resin with a flame retardant content of 10wt%:

[0043] (1) 12g of the lignin-based intumescent flame retardant (LMA) powder obtained in step (3) of Example 2 was dissolved in 8g of N,N-dimethylformamide (DMF);

[0044] (2) 108g bisphenol A type epoxy resin is joined in the fire retardant that step (1) dissolves and continues reaction 40min at 60 ℃ and prepares the flame retardant epoxy resin that flame retardant content is 10wt%;

[0045] (3) Using a vacuum-assisted molding process, the carbon fiber after the sizing pretreatment in step (5) of Example 1 is arranged in a vacuum-assisted molding device, and a vacuum operation is performed, and the curing agent diethylenetriamine is mixed with the step (2) by negative pressure. ) The flame retardant epoxy resin obtained is mixed evenly according to the mass ratio of 9.2:100, then injected into the vacuum assisted molding device, pumpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com