Silicon nanostructured heterojunction solar cell and preparation method thereof

A technology of solar cells and nanostructures, applied in the field of solar cells, can solve the problems of reducing device production costs, reducing lattice order, degrading device performance, etc., achieving reductions in preparation costs and energy consumption, reducing interfacial recombination rates, and device The effect of stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

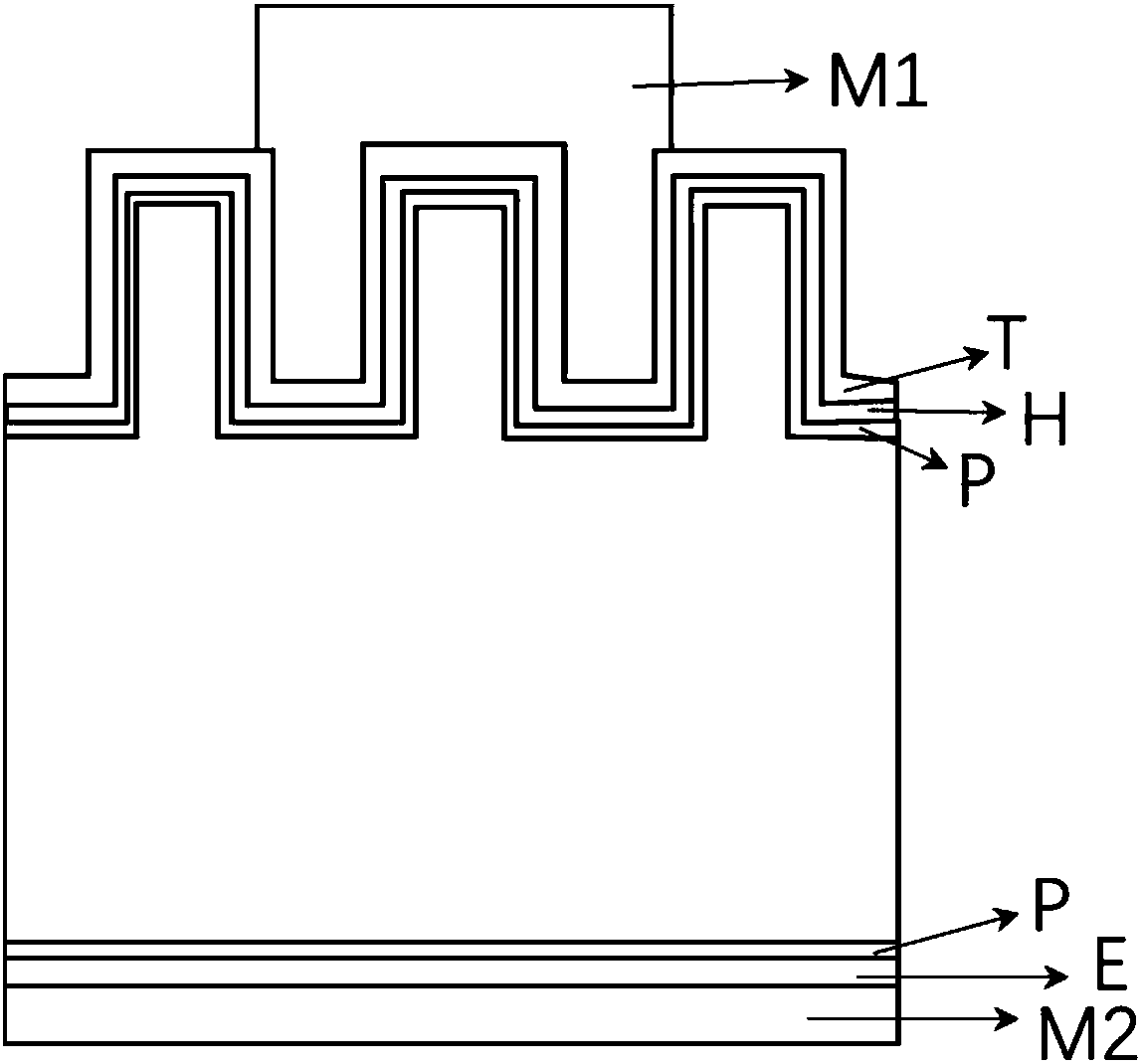

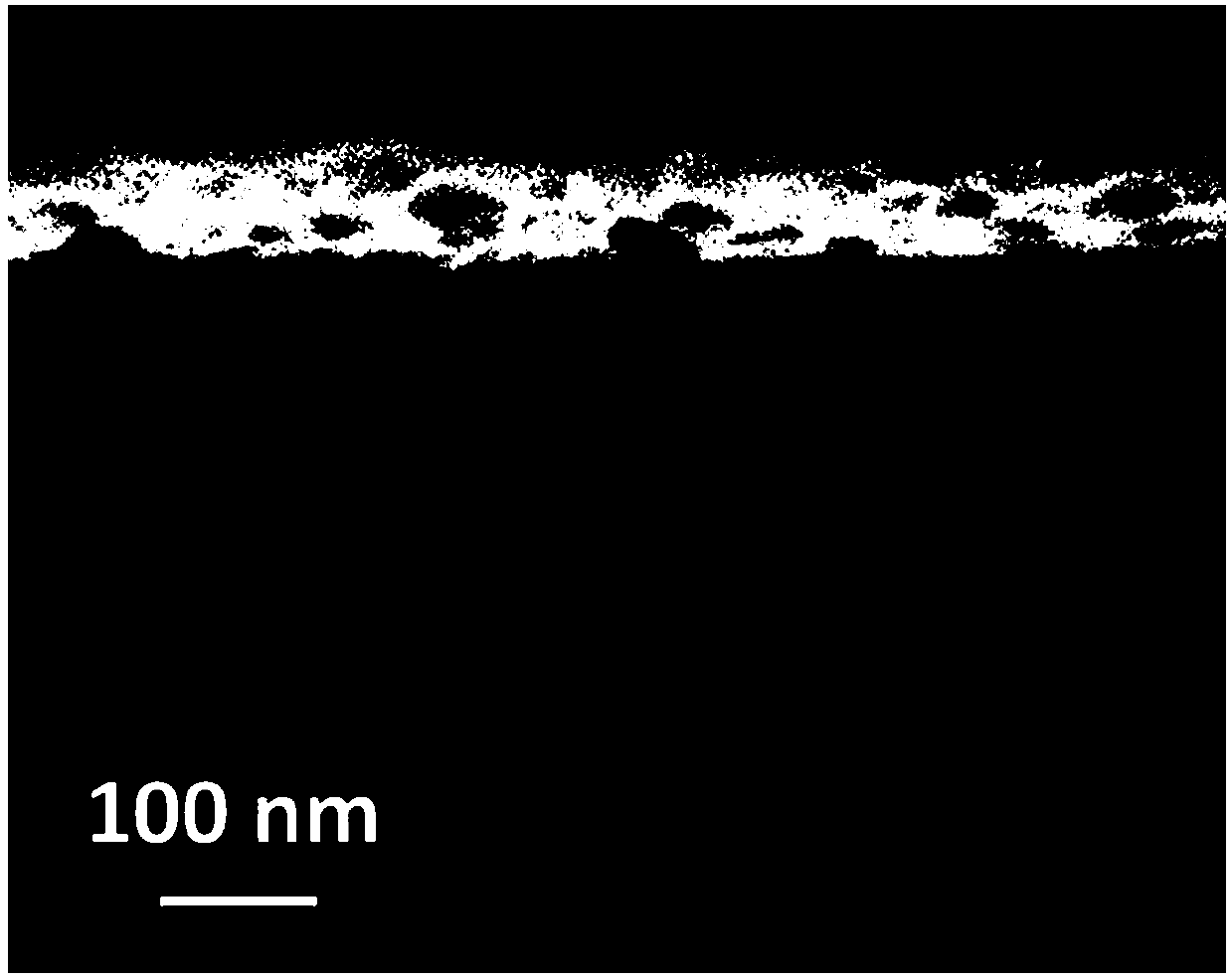

[0029] The structure of a silicon nanostructure heterojunction solar cell in this embodiment is as follows figure 1 As shown, its cross-sectional scanning electron microscope photograph is shown in figure 2 As shown, it includes from top to bottom: metal grid line electrode M1, transparent electrode T, undoped hole transport layer H, ultra-thin silicon oxide passivation layer P, crystalline silicon nanostructure substrate S, ultra-thin silicon oxide Passivation layer P, undoped electron transport layer E and metal back electrode M2.

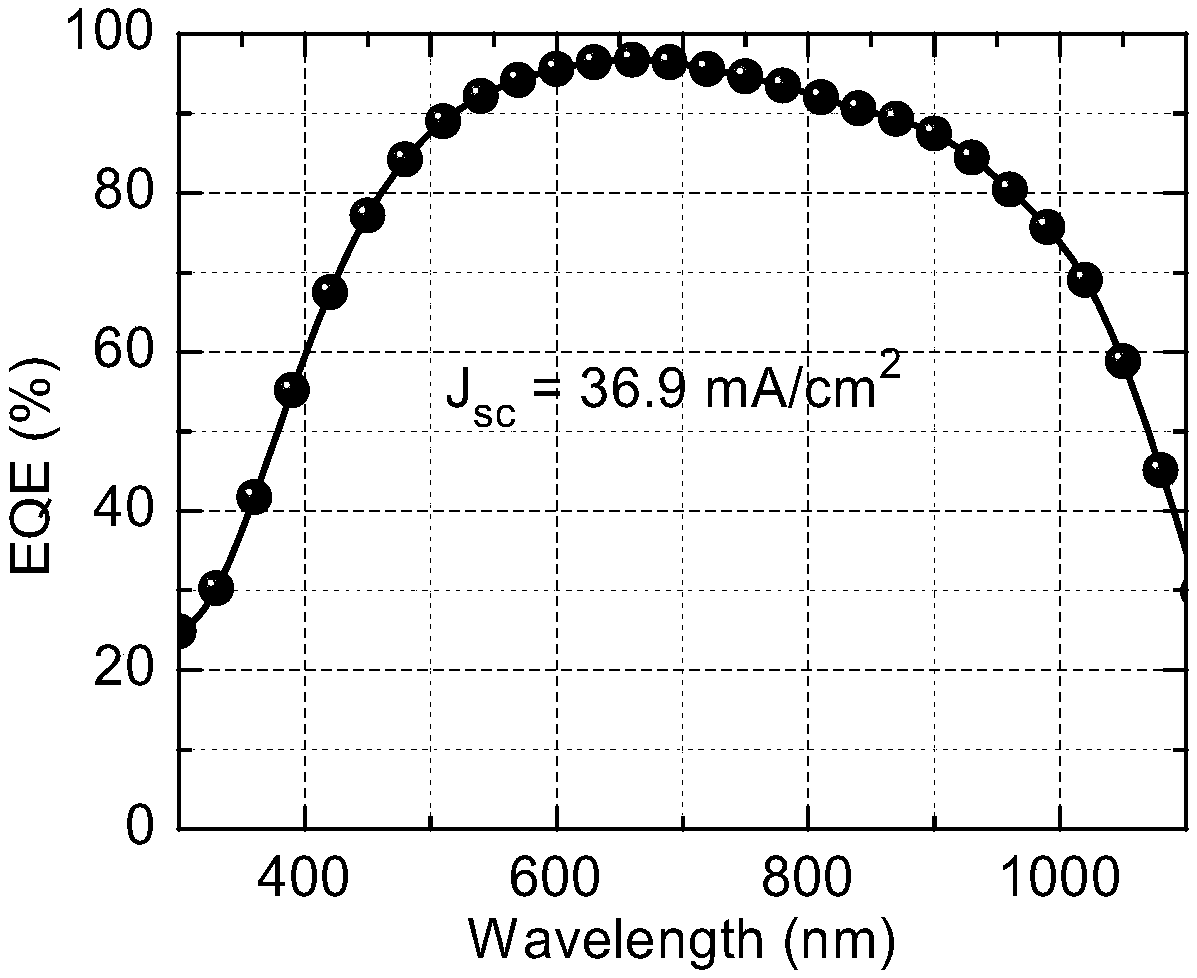

[0030] The thickness of the ultra-thin silicon oxide passivation layer P is 1.5nm; the transparent electrode T is indium tin oxide with a thickness of 80nm; the undoped hole transport layer H is a molybdenum oxide film with a thickness of 10nm; the undoped electron transport layer E is The cesium carbonate film has a thickness of 2 nm; the crystalline silicon nanostructure substrate S is a single crystal silicon nanowire substrate with a thickn...

Embodiment 2

[0040] The structure of a silicon nanostructure heterojunction solar cell in this embodiment is as follows figure 1 As shown, it includes from top to bottom: metal grid line electrode M1, transparent electrode T, undoped hole transport layer H, ultra-thin silicon oxide passivation layer P, crystalline silicon nanostructure substrate S, ultra-thin silicon oxide Passivation layer P, undoped electron transport layer E and metal back electrode M2.

[0041] The thickness of the ultra-thin silicon oxide passivation layer P is 0.7m; the transparent electrode T is indium tin oxide with a thickness of 80nm; the undoped hole transport layer H is a vanadium oxide film with a thickness of 15nm; the undoped electron transport layer E is The cesium carbonate film has a thickness of 2 nm; the crystalline silicon nanostructure substrate S is a single crystal silicon nanowire substrate with a thickness of 150 μm.

[0042] The silicon nanostructure heterojunction solar cell of this embodiment ...

Embodiment 3

[0051] The structure of a silicon nanostructure heterojunction solar cell in this embodiment is as follows figure 1 As shown, it includes from top to bottom: metal grid line electrode M1, transparent electrode T, undoped hole transport layer H, ultra-thin silicon oxide passivation layer P, crystalline silicon nanostructure substrate S, ultra-thin silicon oxide Passivation layer P, undoped electron transport layer E and metal back electrode M2.

[0052] The thickness of the ultra-thin silicon oxide passivation layer P is 2nm; the transparent electrode T is indium tin oxide with a thickness of 80nm; the non-doped hole transport layer H is a molybdenum oxide film with a thickness of 20nm; The cesium thin film has a thickness of 2 nm; the crystalline silicon nanostructure substrate S is a single crystal silicon nanohole substrate with a thickness of 200 μm.

[0053] The silicon nanostructure heterojunction solar cell of this embodiment is prepared by the following method:

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com