Flue gas desulfurization and denitrification adsorbent as well as preparation and usage method thereof

A desulfurization, denitrification, and adsorbent technology, applied in the field of flue gas purification, can solve the problem of less research on adsorbents, and achieve the effects of no secondary pollution, simple equipment operation, and mild synthesis conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

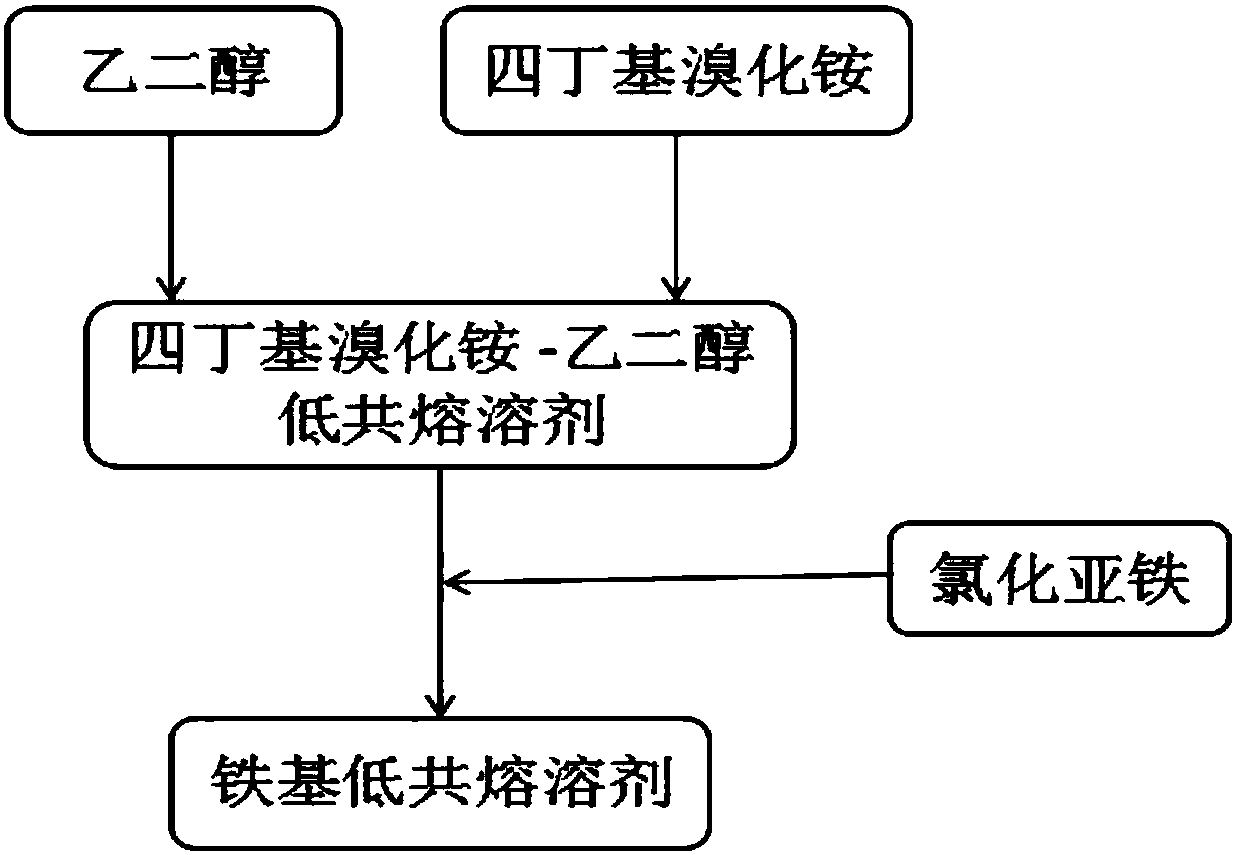

[0038] Take a three-necked flask, put a condensing reflux tube on it, and install a sealed dropping funnel and a stirring device, put tetrabutylammonium bromide and ethylene glycol into the flask, stir, and control the solution temperature at 20±2°C, mix well Obtain tetrabutylammonium bromide-ethylene glycol deep eutectic solvent, the molar ratio of tetrabutylammonium bromide and ethylene glycol is 1:2.

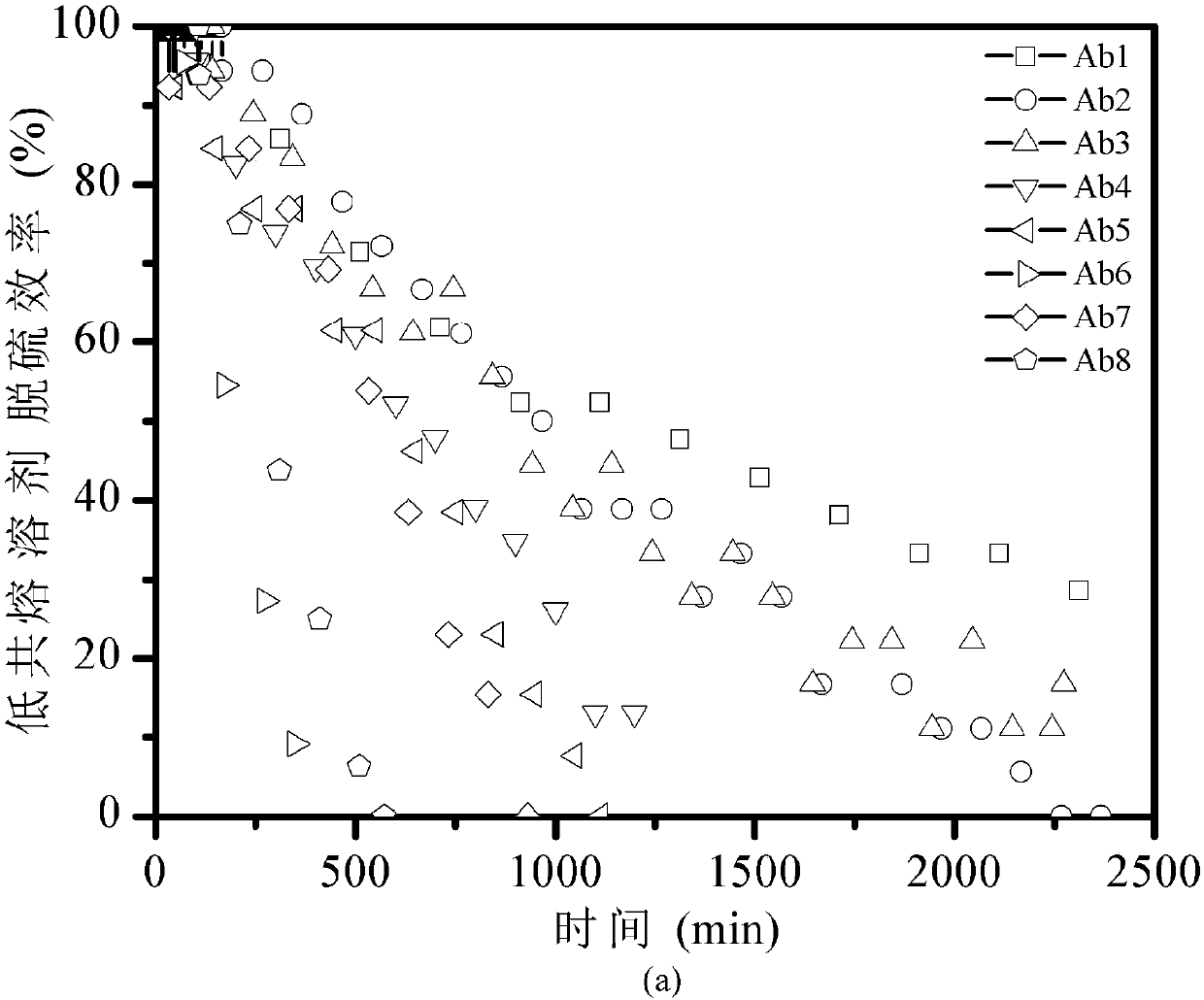

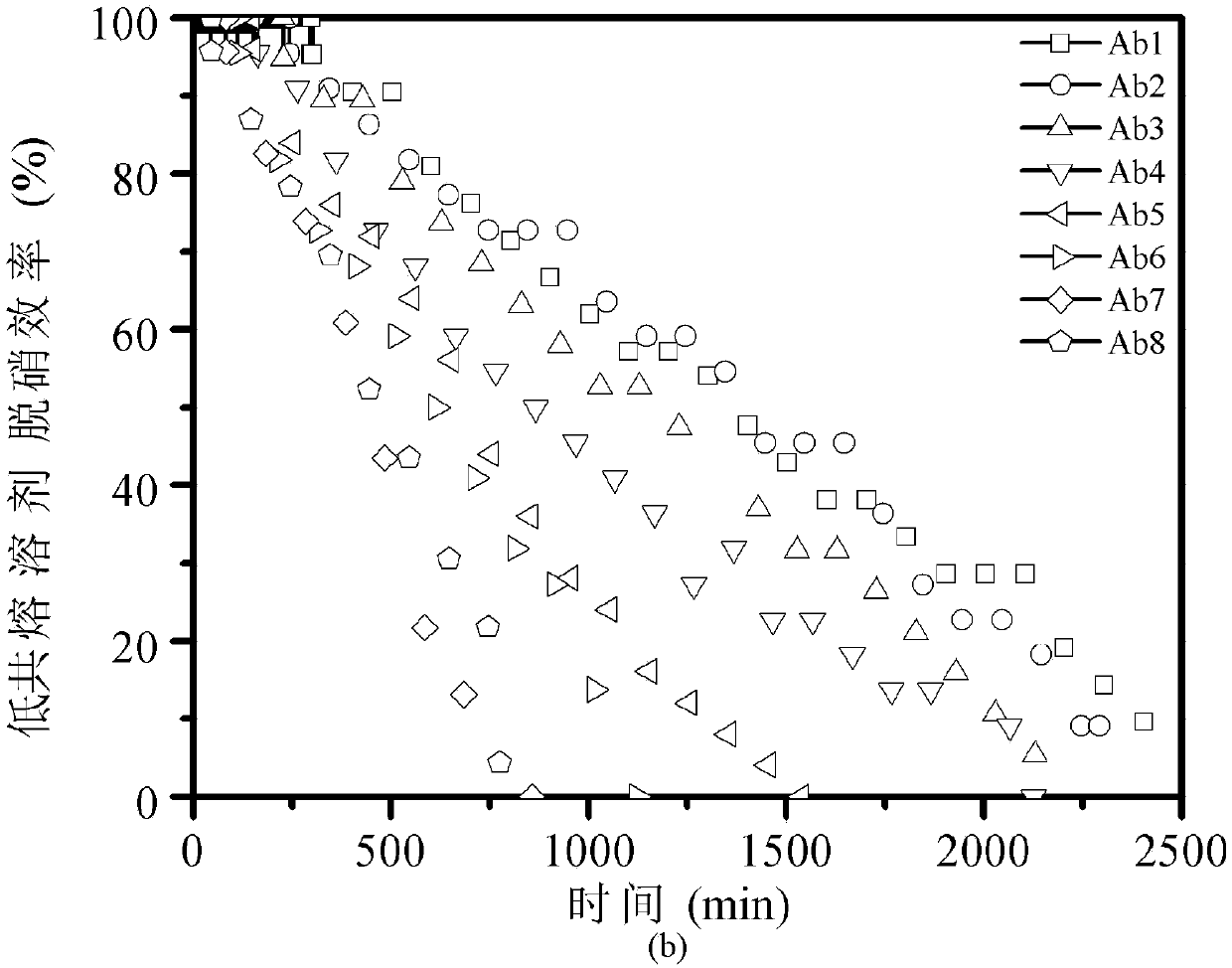

[0039] Take the adsorbent and put it in the bubbling bed reactor, the temperature of the reactor is controlled at 50±2°C, and SO 2 and NO gas are absorbed, and the residence time of the gas in the adsorbent is 2-6s; the adsorbent with absorption equilibrium is placed in a temperature environment of 100±2°C, and the SO 2 and NO desorption experiments. The adsorption equilibrium is reached in 6 minutes, the sulfur capacity S(g) / adsorbent (g) is 0.25, the nitrogen capacity N(g) / adsorbent (g) is 0.026; the equilibrium desorption capacity reaches 90% in 5 minutes.

Embodiment 2

[0041] Take a three-necked flask, put a condensing reflux tube on it, and install a sealed dropping funnel and a stirring device, put tetrabutylammonium bromide and ethylene glycol into the flask, stir, and control the solution temperature at 20±2°C, mix well Obtain tetrabutylammonium bromide-ethylene glycol deep eutectic solvent, the molar ratio of tetrabutylammonium bromide and ethylene glycol is 1:5.

[0042]Take the adsorbent and put it in the bubbling bed reactor, the temperature of the reactor is controlled at 50±2°C, and SO 2 and NO gas are absorbed, and the residence time of the gas in the adsorbent is 2-6s; the adsorbent with absorption balance is placed in a temperature environment of 90-92°C for SO 2 and NO desorption experiments. The adsorption equilibrium is reached in 9 minutes, the sulfur capacity S(g) / adsorbent (g) is 0.3, the nitrogen capacity N(g) / adsorbent (g) is 0.03; the equilibrium desorption capacity reaches 90% in 10 minutes.

Embodiment 3

[0044] Take a three-necked flask, put a condensing reflux tube on it, and install a sealed dropping funnel and a stirring device, put tetrabutylammonium bromide and ethylene glycol into the flask, stir, and control the solution temperature at 20±2°C, mix well Obtain tetrabutylammonium bromide-ethylene glycol deep eutectic solvent, the molar ratio of tetrabutylammonium bromide and ethylene glycol is 1:10.

[0045] Measure the adsorbent and place it in the bubbling bed reactor, the temperature of the reactor is controlled at 50±2°C, and SO 2 and NO gas are absorbed, and the residence time of the gas in the adsorbent is 2-6s; the adsorbent with absorption equilibrium is placed in a temperature environment of 100±2°C, and the SO 2 and NO desorption experiments. The adsorption equilibrium is reached in 15 minutes, the sulfur capacity S(g) / adsorbent (g) is 0.7, the nitrogen capacity N(g) / adsorbent (g) is 0.05; the equilibrium desorption capacity reaches 90% in 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com