Preparation method of carbon dot hybridization polyhedral nickel oxide photocatalyst

A nickel oxide, photocatalyst technology, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, preparation of aminohydroxy compounds, etc., can solve the lack of effective preparation methods for polyhedral nanostructured hybrid materials, etc. problem, to achieve the effect of strong visible light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

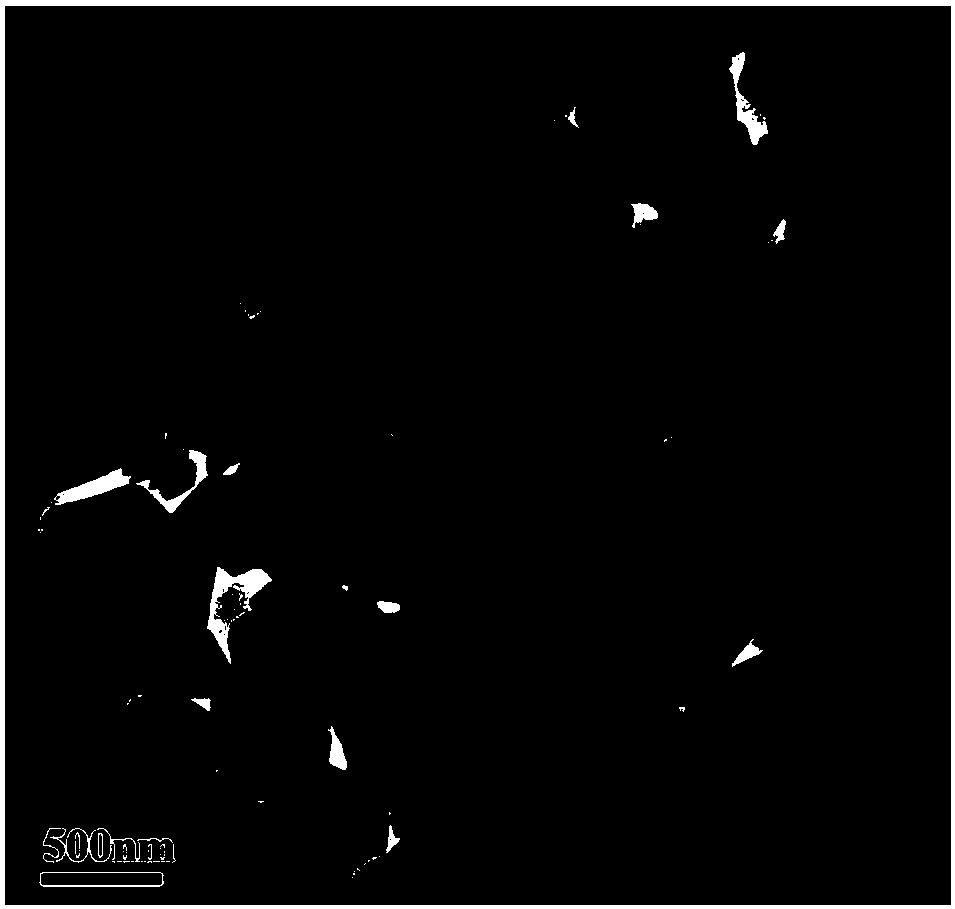

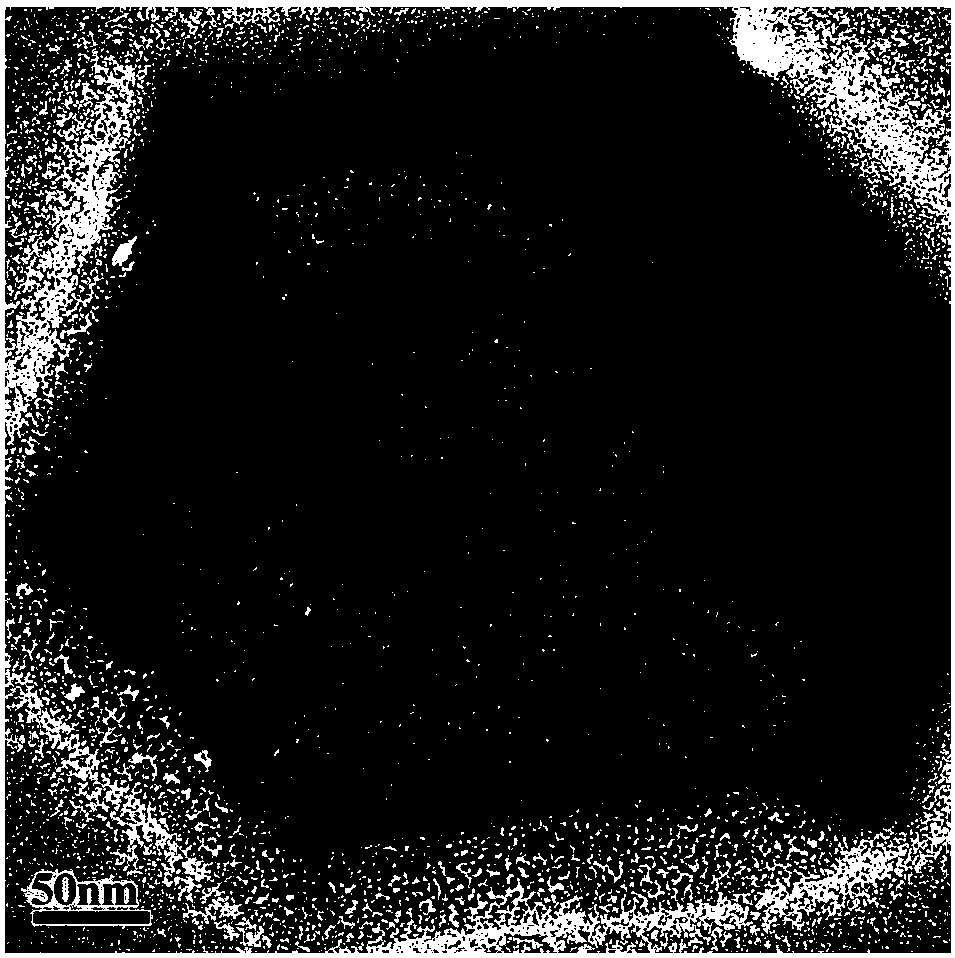

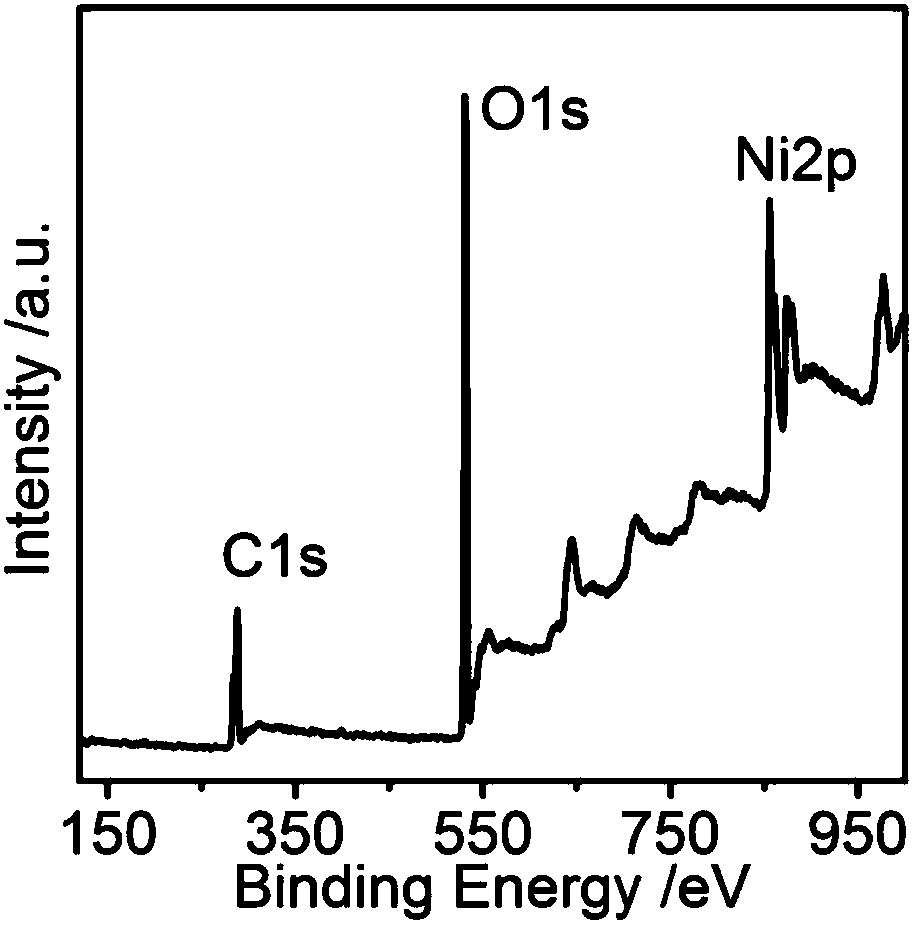

[0023] The preparation method of the carbon point hybrid polyhedral nickel oxide photocatalyst adopts the following steps:

[0024] (1) Mix 60% formic acid with 20% hydrogen peroxide at a volume ratio of 11-15:1 to prepare a mixed solution;

[0025] (2) Take 18-26 milliliters of mixed solution and add fluorescent carbon dots prepared by oxidation etching coal, pitch, activated carbon, graphite or carbon black, and make the concentration of carbon dots in the mixed solution be 1.6-3.0g / L;

[0026] (3) Add nickel powder or foamed nickel to the mixed solution of step (2), and after stirring continuously at a constant temperature of 30° C. for 10-15 hours, remove unreacted nickel powder and foamed nickel;

[0027] (4) Heat the mixed solution obtained in step (3) until it becomes a solid, then heat the obtained solid at 180-200°C for 0.5-3 hours, then cool it down to room temperature naturally, and collect the remaining solid powder to obtain carbon dots. Polyhedral nickel oxide p...

Embodiment 1

[0030] The preparation method of the carbon point hybrid polyhedral nickel oxide photocatalyst adopts the following steps:

[0031] (1) Mix 60% formic acid with 20% hydrogen peroxide at a volume ratio of 11:1 to prepare a mixed solution;

[0032] (2) Take 18 milliliters of mixed solution and add fluorescent carbon dots prepared by oxidation etching coal, pitch, activated carbon, graphite or carbon black, and make the concentration of carbon dots in the mixed solution be 1.6g / L;

[0033] (3) Add nickel powder or foamed nickel to the mixed solution of step (2), and after stirring continuously at a constant temperature of 30° C. for 12 hours, remove unreacted nickel powder and foamed nickel;

[0034] (4) Heat the mixed solution obtained in step (3) until it becomes a solid, then keep the obtained solid at 180-°C for 1 hour, then cool it down to room temperature naturally, and collect the remaining solid powder to obtain carbon-dot hybrid polyhedral nickel oxide photocatalyst.

...

Embodiment 2

[0037] The preparation method of the carbon point hybrid polyhedral nickel oxide photocatalyst adopts the following steps:

[0038] (1) Mix 60% formic acid with 20% hydrogen peroxide at a volume ratio of 13:1 to prepare a mixed solution;

[0039] (2) Take 22 milliliters of mixed solution and add fluorescent carbon dots prepared by oxidation etching coal, pitch, activated carbon, graphite or carbon black, and make the concentration of carbon dots in the mixed solution be 2.0g / L;

[0040] (3) Add nickel powder or foamed nickel to the mixed solution of step (2), and after stirring continuously for 13 hours at a constant temperature of 30° C., remove unreacted nickel powder and foamed nickel;

[0041] (4) Heat the mixed solution obtained in step (3) until it becomes solid, then keep the obtained solid at 190°C for 2 hours, then cool it down to room temperature naturally, and collect the remaining solid powder to obtain carbon-dot hybrid polyhedral nickel oxide photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com