Chemical method for preparing nanoscale flaked silver powder

A flake silver powder, nano-scale technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult mass production of flake silver powder, achieve rapid response, good application prospects, The effect of good settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

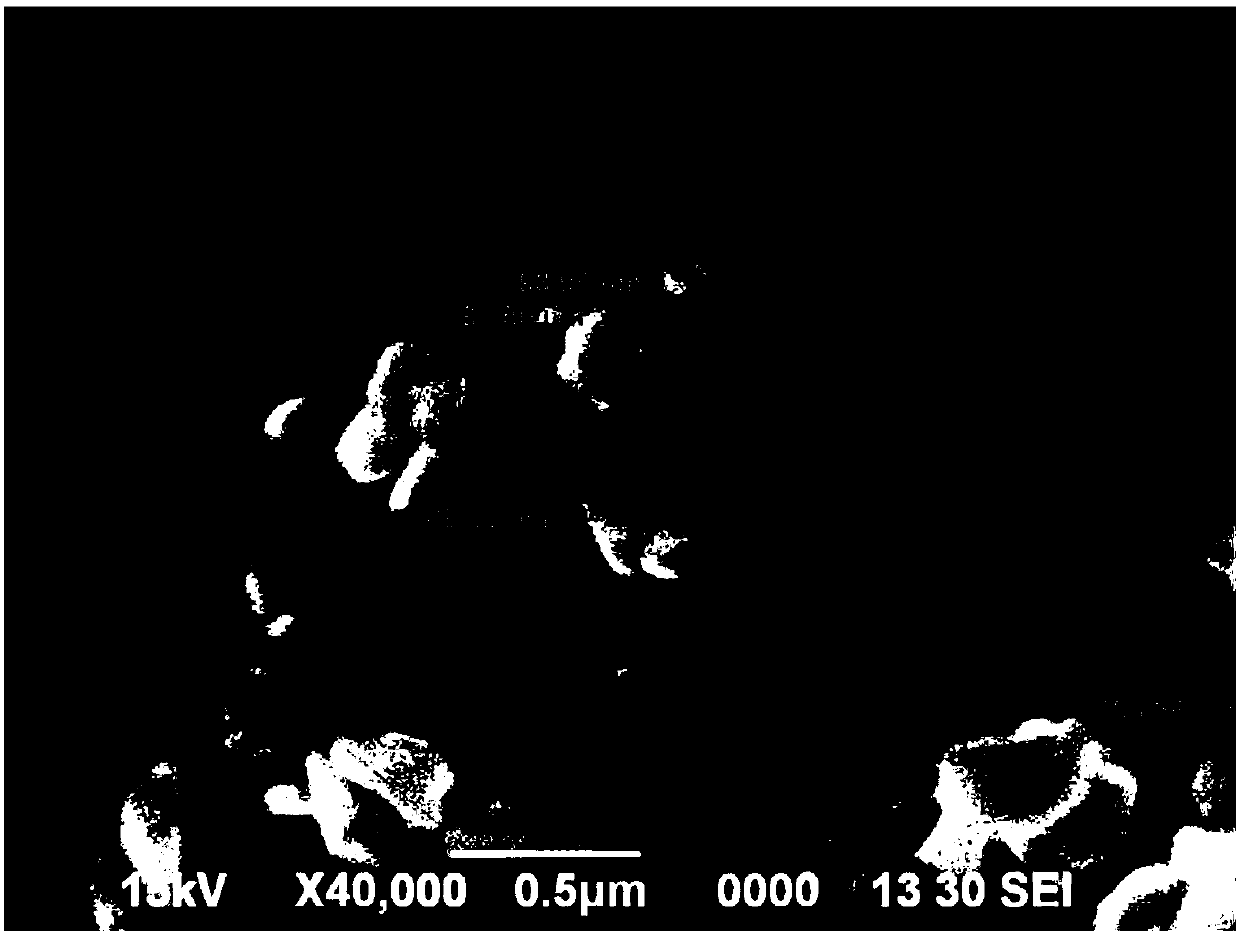

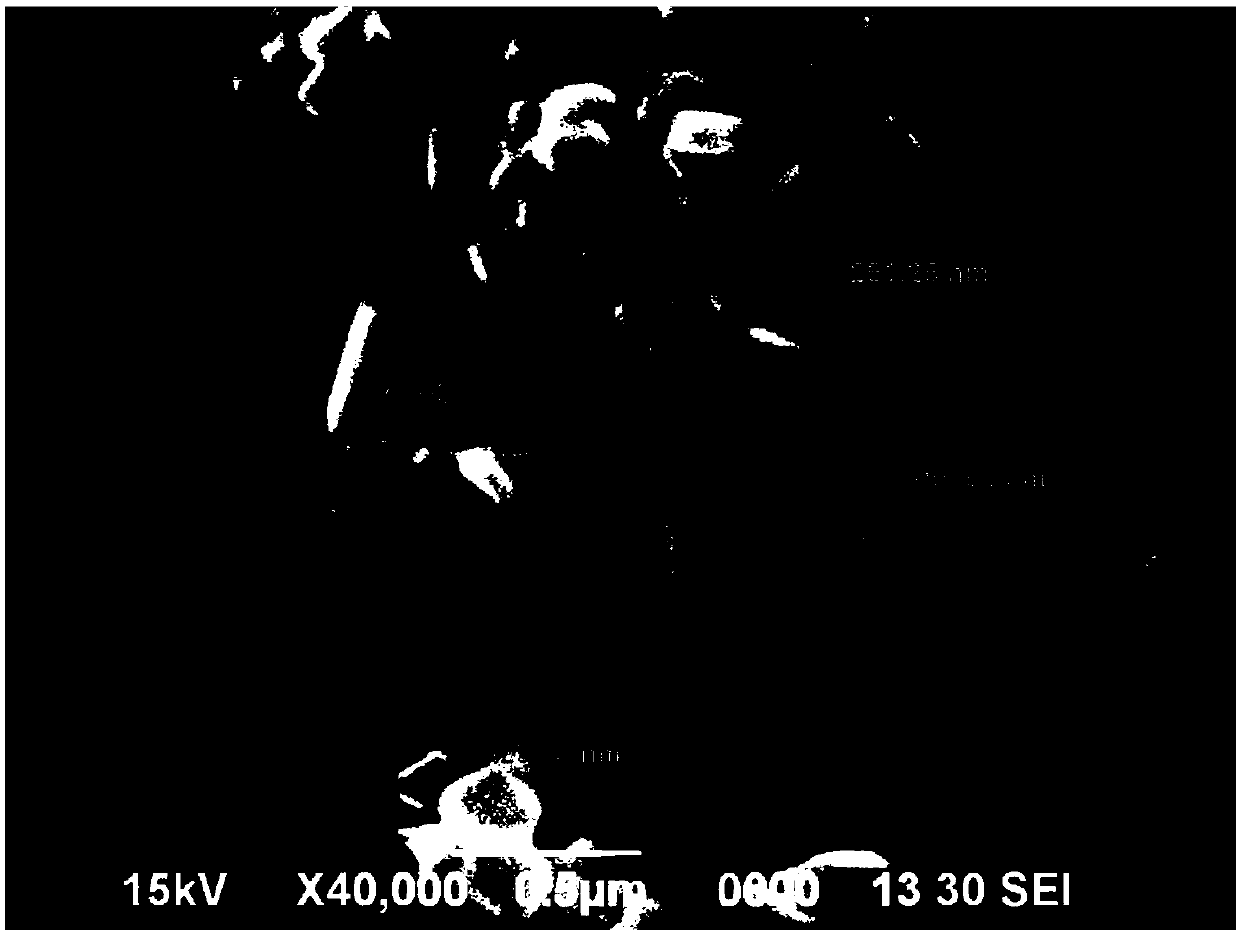

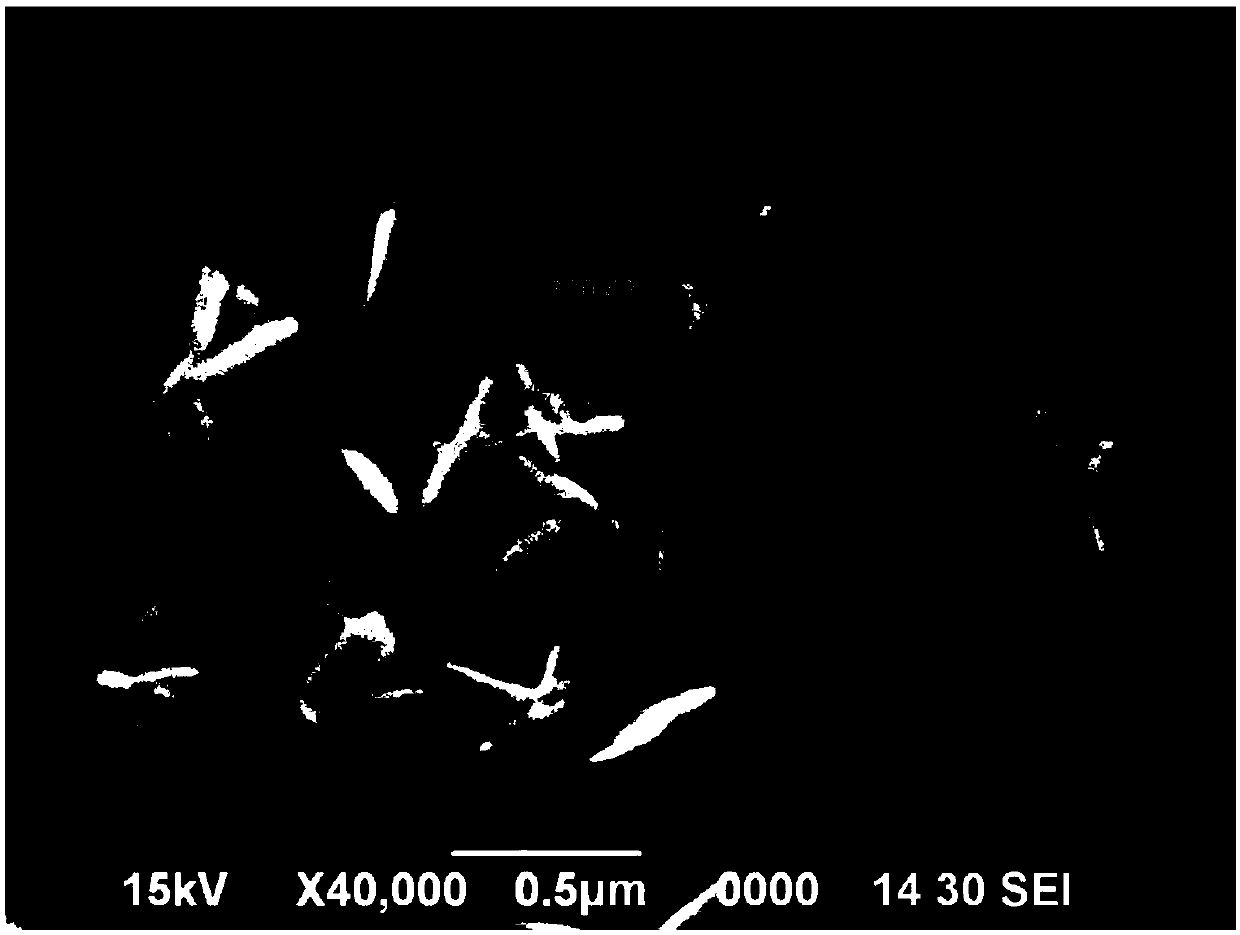

Image

Examples

Embodiment 1

[0026] (1) configuration of reaction raw material solution

[0027] The configuration of liquid A: add 40g of silver nitrate, 200ml of water, and 1g of PVP into a 1L container, and stir at room temperature until the raw materials are fully dissolved;

[0028] Configuration of liquid B: Add 20g of Vc and 200ml of water into a 1L container, stir at room temperature until the raw materials are fully dissolved;

[0029] Configuration of liquid C: Add 3L of water, 0.1g of PVP, 5g of CA, and 1g of CTAB into a 5L container, and stir at room temperature until the raw materials are fully dissolved;

[0030] (2) Preparation of seed crystals

[0031] Add 3L of C solution into a 5L container, add 0.03g of silver nitrate at room temperature, and add 15ml of sodium borohydride solution dropwise after fully dissolving, the concentration of sodium borohydride solution is 0.0038g / ml;

[0032] (3) Preparation of flake silver powder:

[0033] Add liquid A and liquid B into the container conta...

Embodiment 2

[0035] Configuration of liquid A: add 40g of silver nitrate, 350ml of water, and 3g of PVP into a 1L container, and stir at room temperature until the raw materials are fully dissolved;

[0036] Configuration of liquid B: Add 12g of hydrazine hydrate and 350ml of water into a 1L container, and stir at room temperature until the raw materials are fully dissolved.

[0037] Configuration of liquid C: Add 3L of water, 25g of PVP, 3g of CA, 0.5g of CTAB into a 5L container, and stir at room temperature until the raw materials are fully dissolved;

[0038] (2) Preparation of seed crystals

[0039] Add 3L of liquid C into a 5L container, add 0.04g of silver nitrate at room temperature, and add 17ml of sodium borohydride solution dropwise after fully dissolving, the concentration of sodium borohydride solution is 0.0038g / ml;

[0040] (3) Preparation of flake silver powder:

[0041] Add liquid A and liquid B into the container containing liquid C at a constant rate to make them mix e...

Embodiment 3

[0043] Configuration of liquid A: Add 40g silver nitrate, 500ml water, 4g polyvinyl alcohol PVA, 3g polyvinylpyrrolidone PVP into a 1L container, stir at room temperature until the raw materials are fully dissolved;

[0044] Configuration of liquid B: add 32g glucose and 500ml water into a 1L container, stir at room temperature until the raw materials are fully dissolved;

[0045] Configuration of liquid C: Add 3L of water, 50g of PVP, 0.1g of CA, and 0.1g of CTAB into a 5L container, and stir at room temperature until the raw materials are fully dissolved;

[0046] (2) Preparation of seed crystals

[0047] Add 3L of C solution into a 5L container, add 0.06g of silver nitrate at room temperature, add 20ml of sodium borohydride solution dropwise after fully dissolving, the concentration of sodium borohydride solution is 0.0038g / ml;

[0048] (3) Preparation of flake silver powder:

[0049] Add liquid A and liquid B into the container containing liquid C at a constant rate to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com