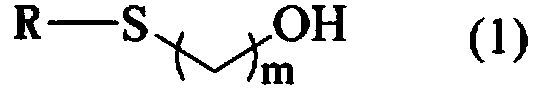

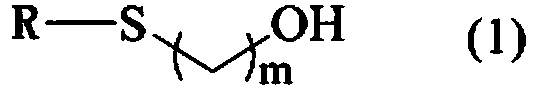

Phosphate-ester dispersing agent and preparing method and application thereof

A technology of dispersant and phosphoric acid ester, applied in the field of phosphoric acid ester dispersant and its preparation and application, can solve the problems of few process steps and low reaction temperature, and achieve the effects of few process steps, low reaction temperature and excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: water-soluble phosphate ester dispersant 1

[0049] Put 40g of xylene and 13.4g of 3-mercapto-1-propanol into a four-neck flask equipped with a condenser tube, a thermometer, and a constant pressure dropping funnel, start stirring, replace nitrogen, and heat up to 75°C. 12.2g of methyl methacrylate, 87.8g of methacrylic acid polyglycol ether (Mn=400) and 0.94g of AIBN mixed solution were added dropwise to the reaction solution through a constant pressure dropping funnel, and dropped for 4 hours. After the addition was complete, the reaction was then incubated for 4 hours, and all solvents and unreacted monomers were distilled off under reduced pressure at 100° C. to obtain polymer monoalcohol P1, which was a light yellow viscous liquid with Mn=1100. Subsequently, the temperature of the colorless liquid was lowered to 60°C, and 11.5 g of polyphosphoric acid (PPA116) was added while vigorously stirring, and the stirring was continued at 90°C for 6 hours to o...

Embodiment 2

[0050] Embodiment 2: water-soluble phosphate ester dispersant 2

[0051] Put 40g of propylene glycol methyl ether acetate and 7.9g of 3-mercapto-1-propanol into a four-neck flask equipped with a condenser tube, a thermometer, and a constant pressure dropping funnel, start stirring, replace nitrogen, and heat up to 70°C. The pre-configured 8.5g of methyl methacrylate, 82.3g of allyl polyethylene glycol ether (Mn=800), 9.2g of styrene and 0.55g of BPO mixed solution were added dropwise through a constant pressure dropping funnel Into the reaction solution, after 4 hours, the dropwise addition was completed, and then the heat preservation reaction was carried out for 4 hours, and all solvents and unreacted monomers were removed by vacuum distillation at 100 ° C to obtain polymer monohydric alcohol P2, which was a light yellow viscous liquid. Mn=1800. Subsequently, the temperature of the colorless liquid was lowered to 60°C, and 6.77g of polyphosphoric acid (PPA116) was added int...

Embodiment 3

[0054] Embodiment 3: highly polar phosphate ester dispersant 3

[0055] Put 40g of xylene and 3.4g of 3-mercapto-1-propanol into a four-neck flask equipped with a condenser tube, a thermometer, and a constant pressure dropping funnel, start stirring, replace nitrogen, and heat up to 75°C. The butyl acrylate of 56.1g, the polyglycol ether of methacrylic acid (Mn=400) of 28.7g, the AIBN mixed solution of the styrene of 15.2g and 0.27g are added dropwise in the reaction solution by constant pressure dropping funnel, The dropwise addition was completed after 4 hours, and then the reaction was kept for 4 hours, and all solvents and unreacted monomers were distilled off under reduced pressure at 100° C. to obtain polymer monohydric alcohol P3, which was a light yellow viscous liquid with Mn=4100. Subsequently, the temperature of the colorless liquid was lowered to 60°C, and 2.85g of polyphosphoric acid (PPA116) was added while vigorously stirring, and the stirring was continued at 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com