A method and equipment for preparing zno-like crystal thin films

A kind of crystal and equipment technology, applied in the field of preparing ZnO crystal thin film, can solve problems such as difficult mass production, and achieve the effect of strong repeatability, easy operation and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

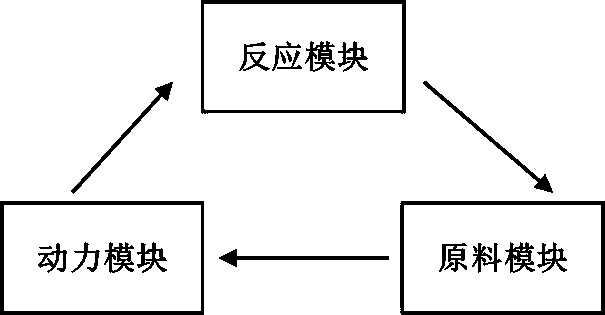

AI Technical Summary

Problems solved by technology

Method used

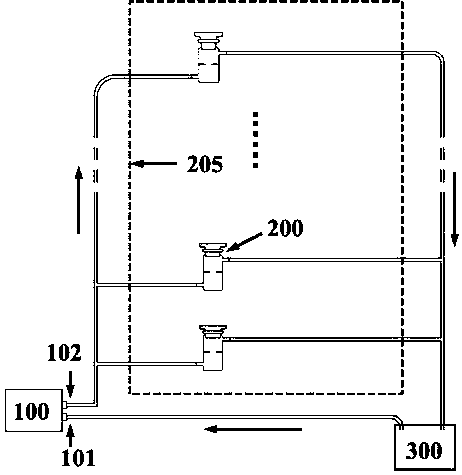

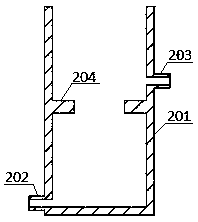

Image

Examples

Embodiment 1

[0020] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0021] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 30nm.

[0022] (3) Solution preparation: 0.2mol Zn(NO 3 ) 2 ▪6H 2 O, 0.02mol HMTA and 0.5mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0023] Growth of ZnO crystal materi...

Embodiment 2

[0025] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0026] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 50nm.

[0027] (3) Solution preparation: 0.3mol Zn(NO 3 ) 2 ▪6H 2 O, 0.05mol HMTA and 2mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0028] Growth of ZnO crystal materia...

Embodiment 3

[0030] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0031] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 30nm.

[0032] (3) Solution preparation: 0.2molZn(NO 3 ) 2 ▪6H 2 O, 0.04mol HMTA and 5mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0033] Growth of ZnO crystal material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com