Method and device for preparing ZnO type crystal thin film

A crystal-like and thin-film technology, applied in the field of preparing ZnO-like crystal thin films, can solve problems such as difficulty in mass production, and achieve the effects of strong repeatability, simple equipment, and favorable promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

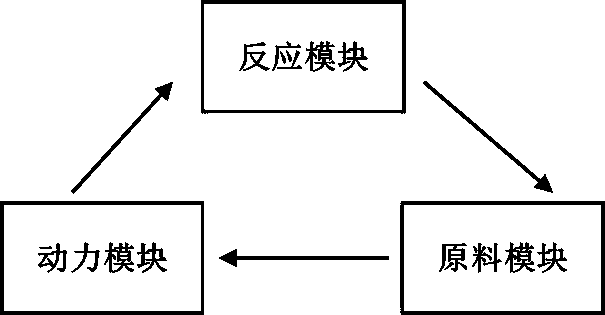

AI Technical Summary

Problems solved by technology

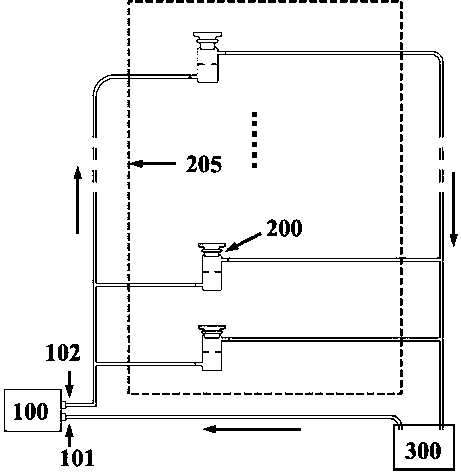

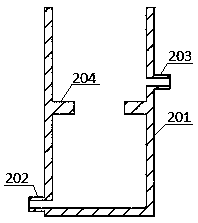

Method used

Image

Examples

Embodiment 1

[0020] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0021] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 30nm.

[0022] (3) Solution preparation: 0.2mol Zn(NO 3 ) 2 ▪6H 2 O, 0.02mol HMTA and 0.5mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0023] Growth of ZnO crystal mater...

Embodiment 2

[0025] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0026] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 50nm.

[0027] (3) Solution preparation: 0.3mol Zn(NO 3 ) 2 ▪6H 2 O, 0.05mol HMTA and 2mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0028] Growth of ZnO crystal materia...

Embodiment 3

[0030] (1) Material cleaning: The oxidized Si substrate material on the surface was ultrasonicated for 15 minutes with toluene, acetone, and ethanol respectively, and then rinsed with deionized water; then boiled with aqua regia prepared with concentrated nitric acid and sulfuric acid for 15 minutes; Rinse with hot deionized water and cold deionized water, and dry with nitrogen gas for later use.

[0031] (2) Growth of ZnO seed crystal layer: place the cleaned substrate material in the cavity of the magnetron sputtering equipment, and vacuum up to 8 × 10 -4 pa; the purity of the ZnO ceramic target is 99.99%, the distance between the target and the substrate material is 7cm; the RF sputtering power is 150w, the sputtering time is 1 minute, and the ZnO thickness is about 30nm.

[0032] (3) Solution preparation: 0.2molZn(NO 3 ) 2 ▪6H 2 O, 0.04mol HMTA and 5mmol Cu(NO 3 ) 2 Dissolve in 100mL deionized water to obtain a mixed solution.

[0033] Growth of ZnO crystal material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com