Solid phase extraction column for simultaneous purification of various mycotoxins and application thereof

A solid-phase extraction column and mycotoxin technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of poor enrichment and purification effect, undetectable, complicated reagents, etc., and achieve convenient pre-treatment, reduce consumption, and prepare Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: raw material and preparation of solid phase extraction column

[0042] 1. Raw materials:

[0043] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0044] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 μm;

[0045] (3) Carboxylated multi-walled carbon nanotube filler: 10 mg of carboxylated multi-walled carbon nanotube filler with a length of 50 μm;

[0046] (4) Reversed-phase chromatography packing: 200 mg of reverse-phase chromatography packing C with a particle size of 40-60 μm 18 ;

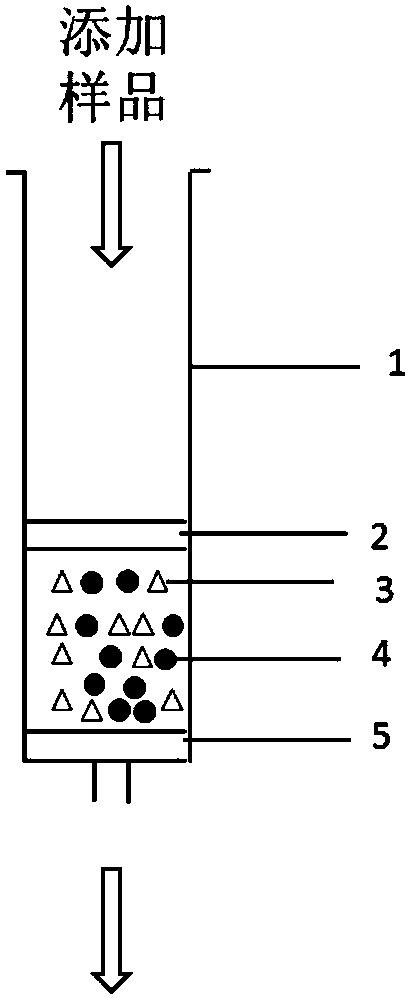

[0047] 2. Assembly method (see attached figure 1 )

[0048] Carboxylated multi-walled carbon nanotubes (attached figure 1 4) and reversed-phase chromatography packing (attached figure 1 3) After mixing uniformly according to a certain ratio to obtain the compound packing, pour it into polypropylene or glass column tube (attached figure 1 In step 1), first fill a piece of sieve ...

Embodiment 2

[0049] Embodiment 2: raw material and preparation of solid phase extraction column

[0050] 1. Raw materials

[0051] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0052] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 μm;

[0053] (3) Carboxylated multi-walled carbon nanotube filler: 20 mg of carboxylated multi-walled carbon nanotube filler with a length of 50 μm;

[0054] (4) Reversed-phase chromatography packing: 200 mg of reverse-phase chromatography packing C with a particle size of 40-60 μm 18 ;

[0055] 2. Assembly method

[0056] First mix carboxylated multi-walled carbon nanotubes and reversed-phase chromatographic fillers in a certain proportion to obtain a compound filler, then fill a piece of sieve plate into a polypropylene or glass column tube, add the mixed compound filler, and then fill Insert the second sieve plate and press firmly.

Embodiment 3

[0057] Embodiment 3: raw material and preparation of solid phase extraction column

[0058] 1. Raw materials

[0059] (1) Column tube: 6mL polypropylene or glass column tube with an inner diameter of 12.7mm;

[0060] (2) Sieve plate: polyethylene or polytetrafluoroethylene sieve plate with a pore size of 10-30 μm;

[0061] (3) Carboxylated multi-walled carbon nanotube filler: 20 mg of carboxylated multi-walled carbon nanotube filler with a length of 50 μm;

[0062] (4) Reverse-phase chromatography filler: 200 mg reverse-phase chromatography filler HLB with a particle size of 40-60 μm;

[0063] 2. Assembly method

[0064] First mix carboxylated multi-walled carbon nanotubes and reversed-phase chromatographic fillers in a certain proportion to obtain a compound filler, then fill a piece of sieve plate into a polypropylene or glass column tube, add the mixed compound filler, and then fill Insert the second sieve plate and press firmly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com