Nanosheet Pt/carbonized sawdust material and preparation method thereof

A nano-sheet and sawdust technology, applied in the field of electrochemistry, can solve the problems of complex process, high production cost, low catalyst activity, etc., and achieve the effects of simple process, convenient operation and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

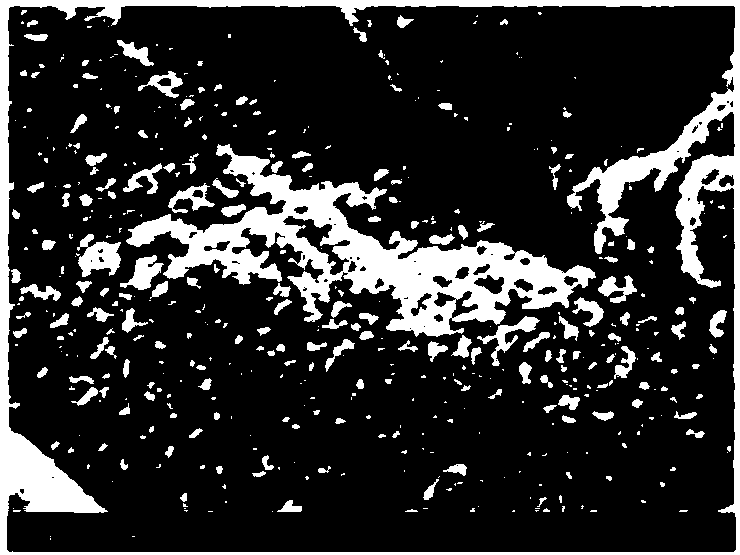

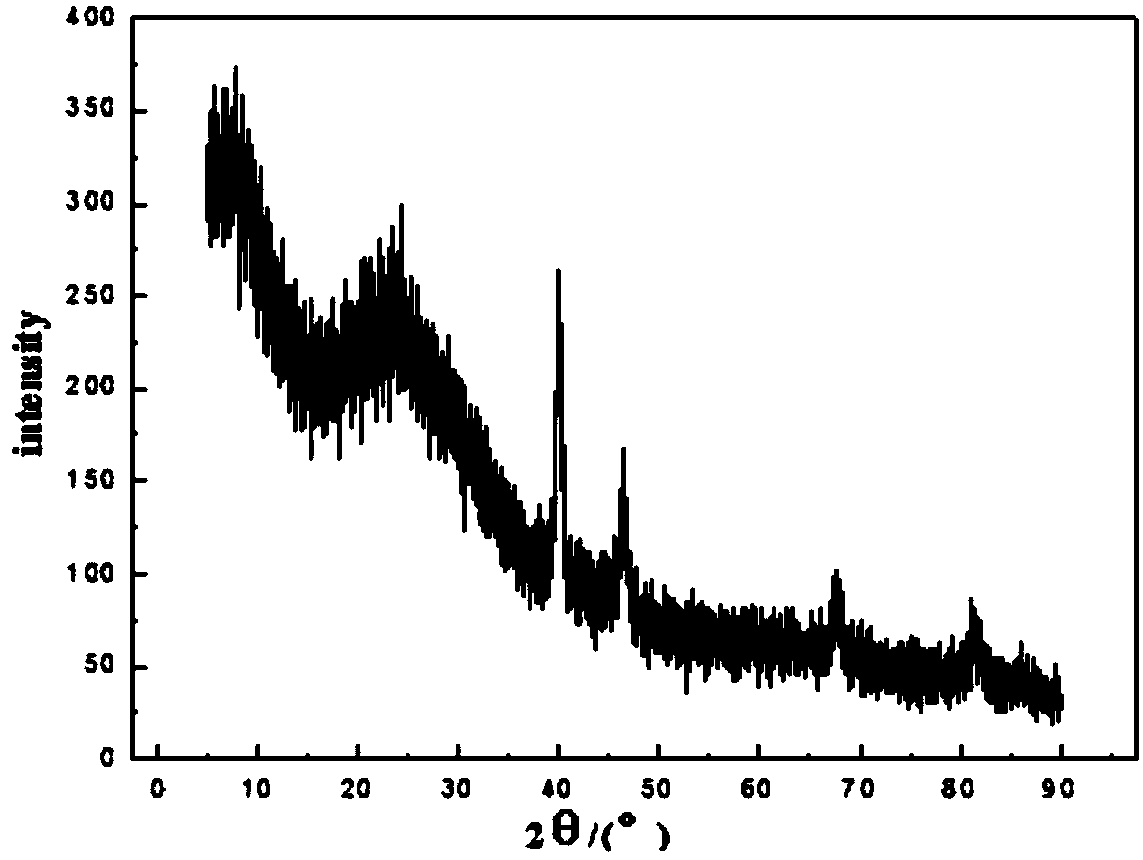

Image

Examples

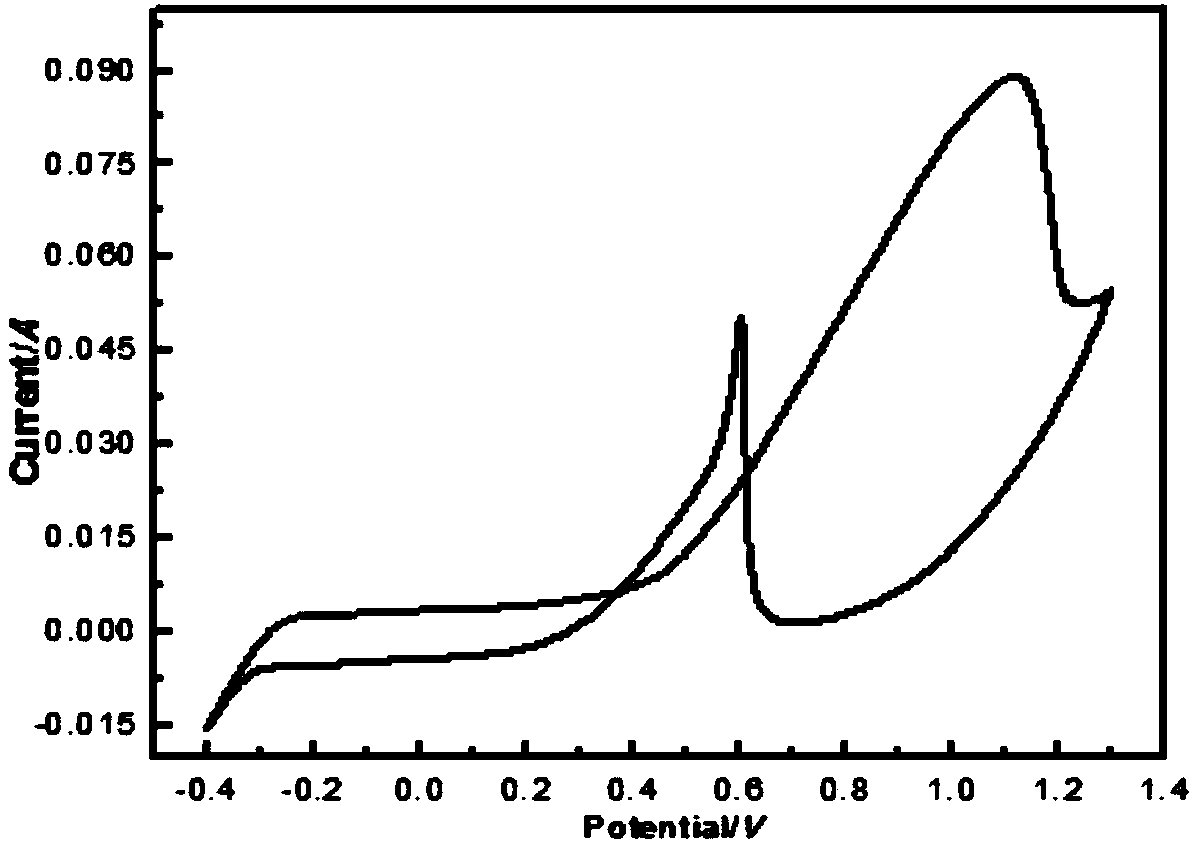

Embodiment 1

[0026] Cut off part of the dried sawdust, ultrasonicate it with deionized water for 5 minutes, wash it once with deionized water, and then dry it. Under the protection of nitrogen, put the sawdust in a steel jade boat, and continue to flow into the atmosphere tube furnace at a distance of 0.05m 3 Nitrogen at a flow rate of / h for 30 minutes to replace the air, then the temperature was raised to 850°C at a rate of 0.5°C / min and kept for 2 hours, cooled to room temperature and taken out.

[0027] A saturated calomel electrode was used as a reference electrode, a platinum wire electrode was used as a counter electrode, and carbonized wood chips were used as a working electrode. 2 SO 4 and 0.005mol / L H 2 PtCl 6 The mixed solution was used as the electrolyte, and Pt was loaded by cyclic voltammetry to obtain Pt / carbonized sawdust materials. Cyclic voltammetry electrodeposition parameters: scan low voltage range -0.4V, scan high voltage range 1.4V, and scan cycle is 500 times. ...

Embodiment 2

[0032] Refer to the method in Example 1 to process wood chips. Under the protection of nitrogen, wood chips are placed in a corundum boat, and continue to flow into the atmosphere tube furnace at a distance of 5m. 3 Nitrogen at a flow rate of / h for 45min to replace the air, the temperature was raised to 850°C at a rate of 1.5°C / min and kept for 3h, cooled to room temperature and taken out. A saturated calomel electrode was used as a reference electrode, a platinum wire electrode was used as a counter electrode, and carbonized wood chips were used as a working electrode, and 0.5mol / L HCOOH and 0.005mol / L H 2 PtCl 6 The mixed solution was used as the electrolyte, and Pt was loaded by cyclic voltammetry, and the electrodeposition parameters of cyclic voltammetry were: scan low voltage range -0.4V, scan high voltage range 1.4V, and scan cycle was 200 times.

Embodiment 3

[0034] After the wood chips are processed by the method in reference example 1, under the protection of nitrogen, the wood chips are placed in a corundum boat, and continue to flow into the atmosphere tube furnace at a distance of 10m 3 Nitrogen at a flow rate of / h for 60min to replace the air, the temperature was raised to 850°C at a rate of 3°C / min and kept for 4h, cooled to room temperature and taken out. A saturated calomel electrode was used as a reference electrode, a platinum wire electrode was used as a counter electrode, and carbonized wood chips were used as a working electrode, and 0.5mol / L CH 3 COOH and 0.005mol / L H 2 PtCl 6 The mixed solution was used as the electrolyte, and Pt was loaded by cyclic voltammetry, and the electrodeposition parameters of cyclic voltammetry were: scan low voltage range -0.4V, scan high voltage range 1.4V, and scan cycle was 20 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com