Soil compound improver with frost heaving resistance

A technology of improver and soil, which is applied in soil conditioning materials, fertilizer mixtures, agriculture, etc., can solve problems such as roadbed frost heave deformation, achieve the effect of improving early strength, satisfying roadbed smoothness, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

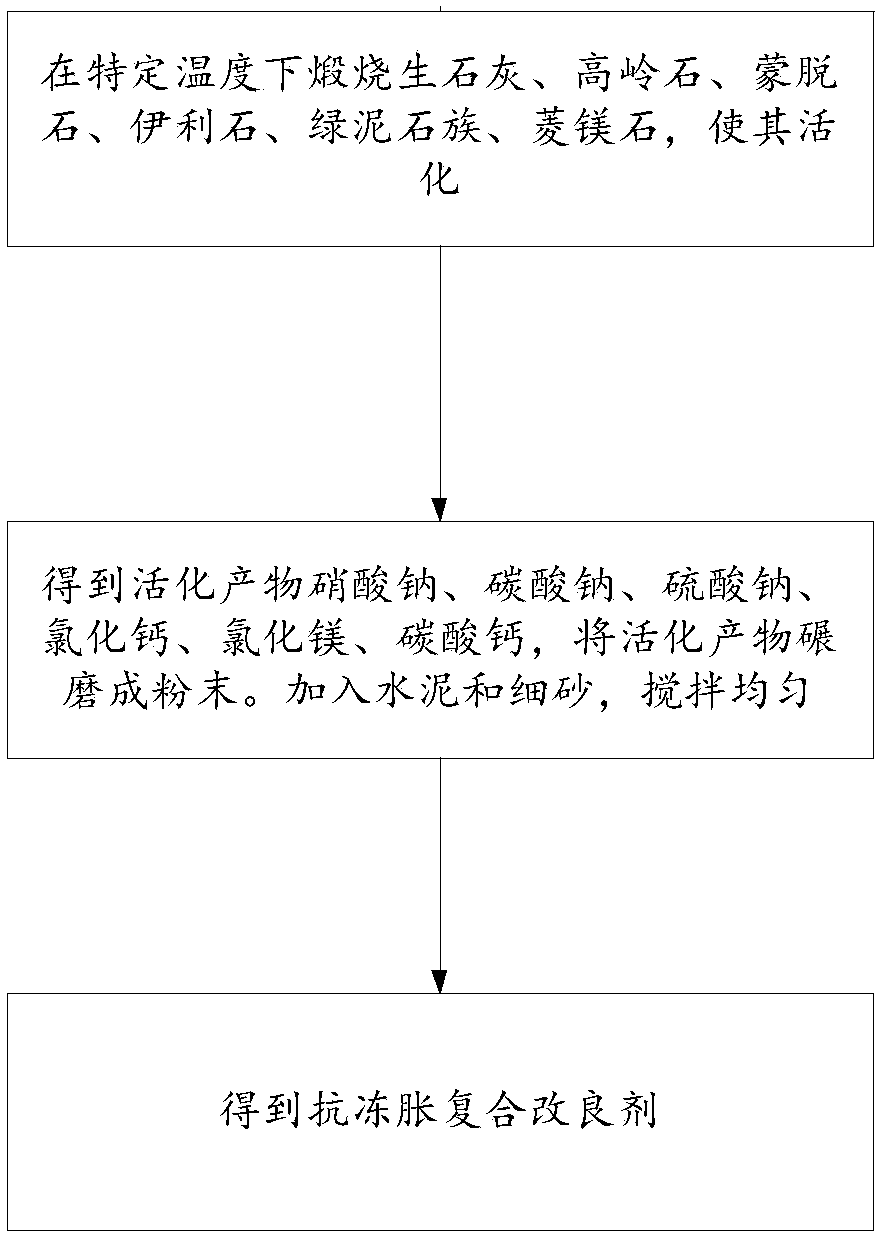

[0044] Calcining quicklime, kaolinite, montmorillonite, illite, chlorite group, and magnesite to obtain 10 parts of sodium nitrate, 100 parts of sodium carbonate, 40 parts of sodium sulfate, 90 parts of calcium chloride, 30 parts of magnesium oxide, 240 parts of calcium carbonate; then add 16000 parts of cement and 150 parts of fine sand; and fully stir to obtain a soil composite improver;

[0045] Then add 550,000 parts of soil, and mix evenly through the improved soil mixing station; during the mixing process, sprinkle water according to the optimal water content of the soil, and mix evenly;

[0046] Transport it to the filling site by vehicle, level the road surface with a leveling mechanism, and compact it with a road roller;

[0047] Finally, cover with two cloths and one film and sprinkle water for curing.

Embodiment 2

[0049] Calcining quicklime, kaolinite, montmorillonite, illite, chlorite group, and magnesite to obtain 30 parts of sodium nitrate, 60 parts of sodium carbonate, 80 parts of sodium sulfate, 50 parts of calcium chloride, 50 parts of magnesium oxide, 200 parts of calcium carbonate; then add 24000 parts of cement and 100 parts of fine sand; and fully stir to obtain a soil composite improver;

[0050] Add water afterwards (wherein the mass ratio of water and soil compound improver is 3:5), fully stir;

[0051] It is injected into the railway or road subgrade by pressure grouting.

Embodiment 3

[0053]Prepare 15 parts of sodium nitrate, 90 parts of sodium carbonate, 50 parts of sodium sulfate, 80 parts of calcium chloride, 35 parts of magnesium oxide, and 230 parts of calcium carbonate, add 19,000 parts of cement and 125 parts of fine sand; stir well, and cremate at high temperature Activate in the furnace, maintain at 340°C for 1.5h, raise the temperature to 1200°C and maintain for 1.5h to obtain a soil compound improver;

[0054] Add water afterwards (wherein the mass ratio of water and soil compound improver is 3:5), fully stir;

[0055] It is injected into the railway or road subgrade by pressure grouting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com