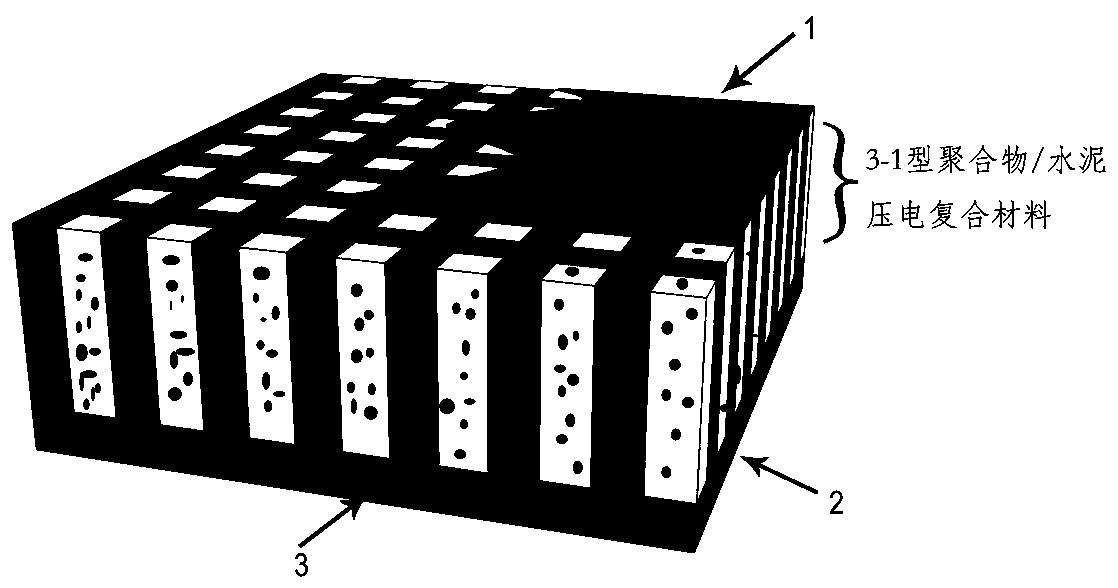

3-1-2 type polymer/cement piezoelectric composite material and its preparation method

A technology of piezoelectric composite materials and polymers, which is applied in the selection of materials for piezoelectric devices or electrostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, etc., which can solve the processing cycle Long time, low production efficiency, low strength of honeycomb ceramics and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

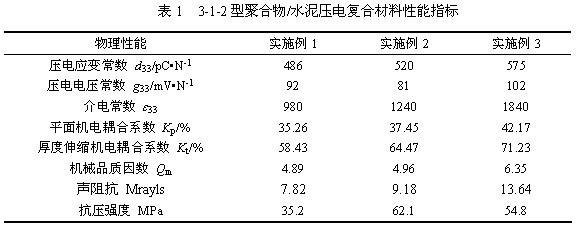

Embodiment 1

[0048] Take 2g of sodium alginate and 6g of lead zirconate titanate piezoelectric ceramic powder, add them into 100ml of water, mix and ball mill for 8 hours, and obtain a uniformly dispersed ceramic slurry.

[0049] Pour the ceramic slurry into a nylon mold, keeping the slurry level at 60 mm. Spray CaCl with a concentration of 1mol / L on the surface of the slurry 2 The solution undergoes a curing reaction to form an initial film with a thickness of 5mm.

[0050] Get 11.1g calcium chloride, 0.1g soluble soybean polysaccharide, add in 50ml water, be mixed with the calcium chloride solution that the concentration that adds metal ion adsorbent is 2mol / L.

[0051] Slowly add the above-mentioned calcium chloride solution added with a metal ion adsorbent into the nylon mold, and let it stand for 12 hours, so that the ceramic slurry in the upper part of the nylon mold forms a calcium alginate ion gel green body with a honeycomb structure. The length of the middle tubular channel is ...

Embodiment 2

[0058] Take 1.5g of sodium alginate and 15g of lead zirconate titanate piezoelectric ceramic powder, add them to 100ml of water, mix and ball mill for 10 hours, and obtain a uniformly dispersed ceramic slurry.

[0059] Pour the ceramic slurry into the nylon mold, keep the liquid level of the slurry at 60mm, and spray CaCl with a concentration of 1mol / L on the surface of the slurry 2 solution, a curing reaction occurs to form an initial film with a thickness of 6mm.

[0060] Get 8.3g calcium chloride, 0.25g chitin, add in 50ml water, prepare the calcium chloride solution that the concentration that adds metal ion adsorbent is 1.5mol / L.

[0061] Add the prepared calcium chloride solution into the nylon mold and let it stand for 18 hours to form a calcium alginate ion gel body with a honeycomb structure with a length of 25 mm long tubular channels.

[0062] Put the nylon mold in a water bath at 50°C, so that the liquid level of the water bath is about 30 mm higher than the botto...

Embodiment 3

[0068] Take 1g of sodium alginate and 25g of lead zirconate titanate piezoelectric ceramic powder, add them to 100ml of water, mix and ball mill for 10 hours, and obtain a uniformly dispersed ceramic slurry.

[0069] Pour the ceramic slurry into the nylon mold, keep the liquid level of the slurry at 60mm, and spray CaCl with a concentration of 1mol / L on the surface of the slurry 2 The solution undergoes a curing reaction to form an initial film with a certain thickness.

[0070] Get 5.6g calcium chloride, 0.75g carboxymethyl chitosan, add in 50ml water, prepare the concentration 1mol / L calcium chloride solution that adds metal ion adsorbent.

[0071] Add the prepared calcium chloride solution into the nylon mold and let it stand for 24 hours to form a calcium alginate ion gel green body with a honeycomb structure. The length of the tubular channel in the green body is 25mm.

[0072] Put the nylon mold in a water bath at 60°C, so that the liquid level of the water bath is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com