High nitrogen high concentration organic wastewater purification system

A technology for organic wastewater and purification systems, which is applied in the fields of organic compound/hydride/coordination complex catalysts, water pollutants, water/sewage treatment, etc. Few studies, stay in the small test stage, etc., to achieve the effects of improving wastewater treatment efficiency, short time required for film hanging, strong hydrophilicity and bioaffinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

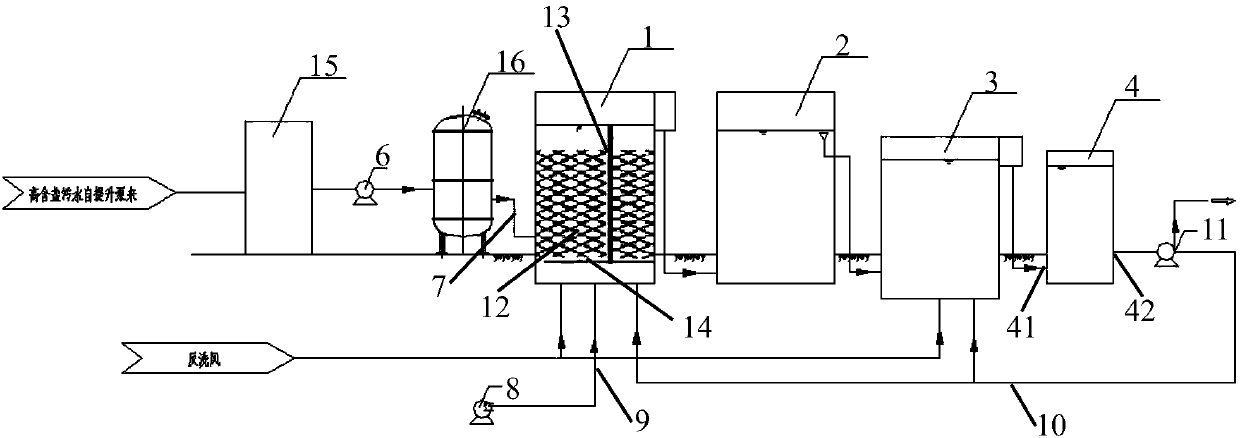

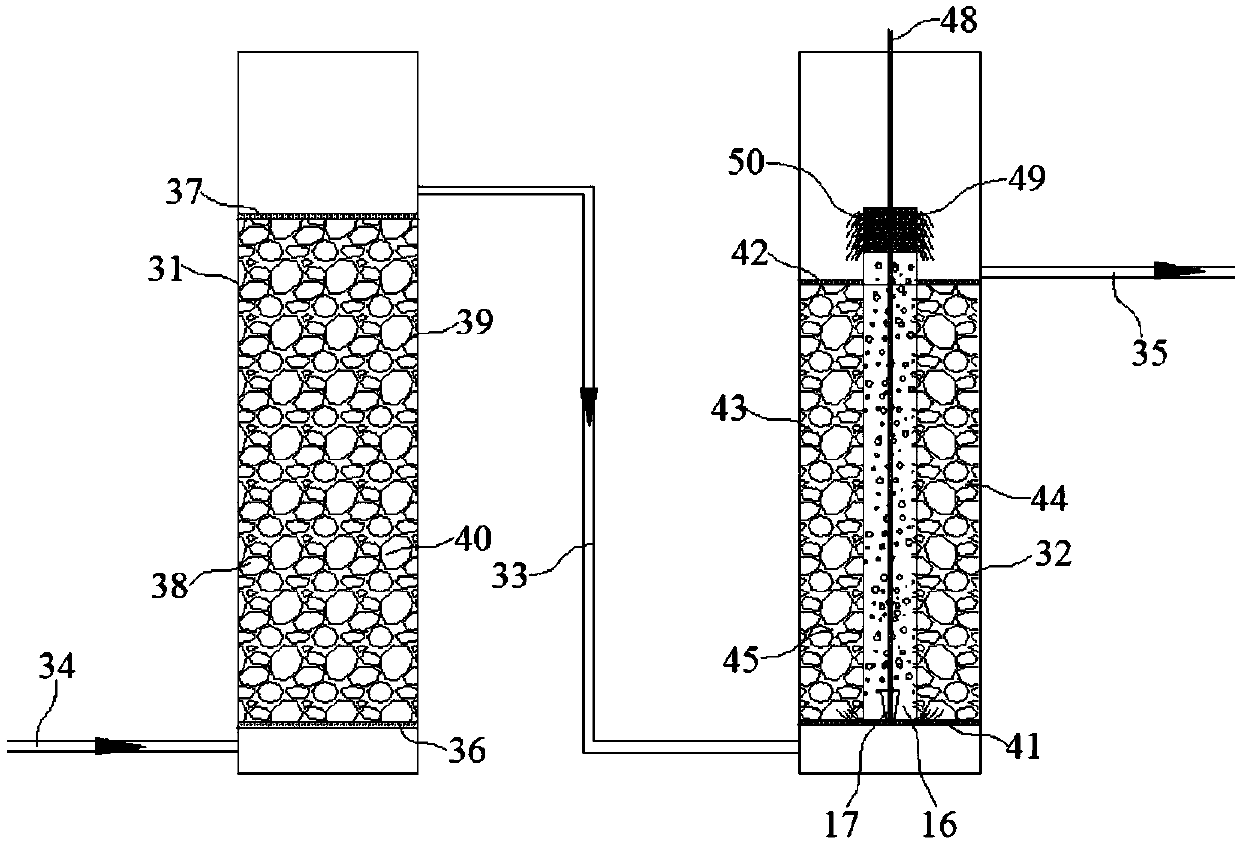

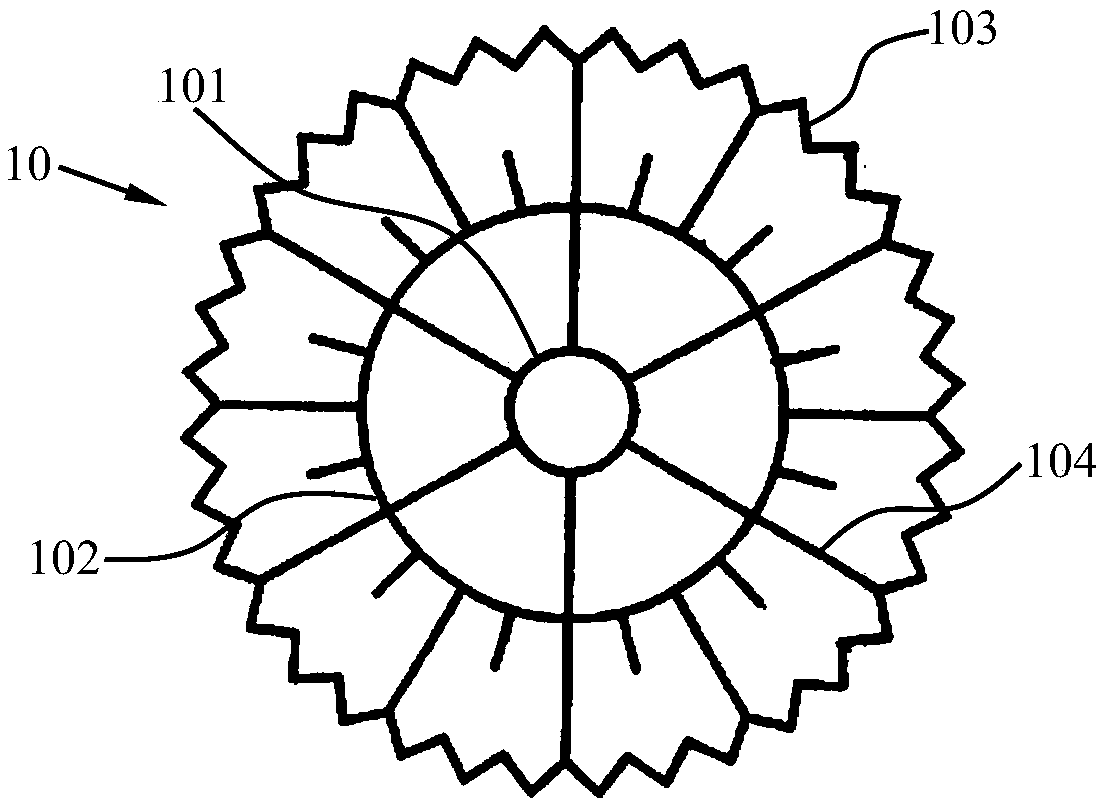

[0054] Embodiment 1~4: A kind of high-nitrogen high-concentration organic wastewater purification system comprises catalytic oxidation pond 1, oxidation stabilization pond 2, post-biochemical BAF pond 3, clear water pond 4, sump pond 15 and filter 16, and described catalytic oxidation Pool 1, oxidation stabilization pool 2, post-biochemical BAF pool 3 and clear water pool 4 are connected through transmission pipeline 5 in turn, and described filter 16 is connected to catalytic oxidation pool 1 inside through water inlet pipeline 7, and an ozone generator 8 passes gas The pipeline 9 is connected to the inside of the catalytic oxidation tank 1, and the clean water tank 4 is provided with a water inlet 41 and a water outlet 42, and the water inlet 41 of the clean water tank 4 is connected with the post-biochemical BAF tank 3 through a transmission pipeline 5, so that The water outlet hole 42 of the clear water tank 4 is connected to one end of a backwash pump 11, and the other end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com