Geopolymer heat protection material, and preparation method and spraying process thereof

A thermal protection material and geopolymer technology, applied in building construction, cement production, construction, etc., can solve the problems of inability to meet the fire protection requirements of large building structures, unsuitable spray construction technology, and unfavorable large-area construction, etc. The effect of reducing adverse effects, realizing efficient utilization, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The composition of a geopolymer thermal protection material includes metakaolin, water glass, water, sodium hydroxide, titanium dioxide, glycerol, fine sand, aluminum hydroxide, and boric acid. The mass ratio of the components of the mixture is: metakaolin: fly ash: water glass (modulus Ms=1.56): glycerol: titanium dioxide: fine sand: aluminum hydroxide: boric acid=1.00:0.30:1.40:0.40: 0.12:4.80:0.40:0.02. The particle size of the metakaolin and fly ash is not greater than 0.5mm. The protective layer thickness of sprayed geopolymer mortar is about 10mm.

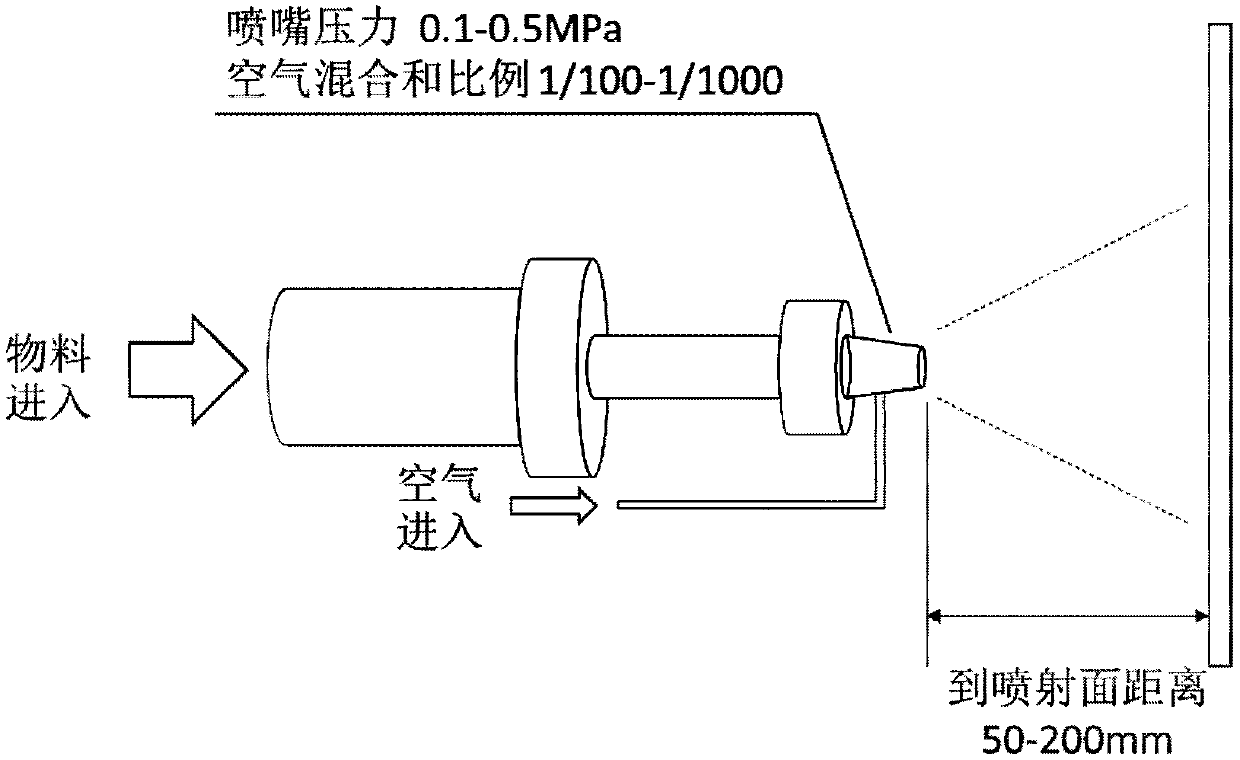

[0035] The spraying process of above-mentioned geopolymer thermal protection material comprises the following steps:

[0036] 1) Use a water gun to flush the spray surface to remove surface impurities, so that the spray material and the sprayed surface have reliable adhesion;

[0037] 2) provide the fresh mixture of geopolymer thermal protection material that can be used for spraying, and the preparation process of ...

Embodiment 2

[0046] The composition of a geopolymer thermal protection material includes: metakaolin, water glass, water, sodium hydroxide, titanium dioxide, glycerin, fine sand, aluminum hydroxide, and boric acid. The mass ratio of the components of the mixture is: metakaolin: fly ash: water glass (modulus Ms=1.56): glycerol: titanium dioxide: fine sand: aluminum hydroxide: boric acid=1.00:0.25:1.50:0.30: 0.15:4.80:0.40:0.05. The particle size of the metakaolin and fly ash is not greater than 0.5mm. The protective layer thickness of sprayed geopolymer mortar is about 25mm.

[0047] The spraying process of above-mentioned geopolymer thermal protection material comprises the following steps:

[0048] 1) Use a water gun to flush the sprayed surface to remove surface impurities, so that the sprayed material and the sprayed surface have reliable adhesion;

[0049] 2) provide the fresh mixture of geopolymer thermal protection materials that can be used for spraying, and the preparation proce...

Embodiment 3

[0059] The composition of a geopolymer thermal protection material includes: metakaolin, water glass, water, sodium hydroxide, titanium dioxide, glycerin, fine sand, aluminum hydroxide, and boric acid. The mass ratio of the components of the mixture is: metakaolin: fly ash: water glass (modulus Ms=1.56): glycerol: titanium dioxide: fine sand: aluminum hydroxide: boric acid=1.00:0.35:1.57:0.23: 0.12:4.80:0.40:0.08. The particle size of the metakaolin and fly ash is not greater than 0.5mm. The protective layer thickness of sprayed geopolymer mortar is about 50mm.

[0060] The spraying process of above-mentioned geopolymer thermal protection material comprises the following steps:

[0061] 3) Use a water gun to flush the spray surface to remove surface impurities, so that the spray material and the spray surface have reliable adhesion;

[0062] 4) provide the geopolymer thermal protection material fresh mixture that can be used for spraying, and described fresh mixture prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com