Nickel-based alloy powder and a preparing method thereof

A nickel-based alloy and powder technology, which is applied in the field of nickel-based alloy powder and its preparation, can solve the problems of low high-temperature resistance strength and corrosion resistance, and achieve the effects of improving corrosion resistance, high-temperature strength, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

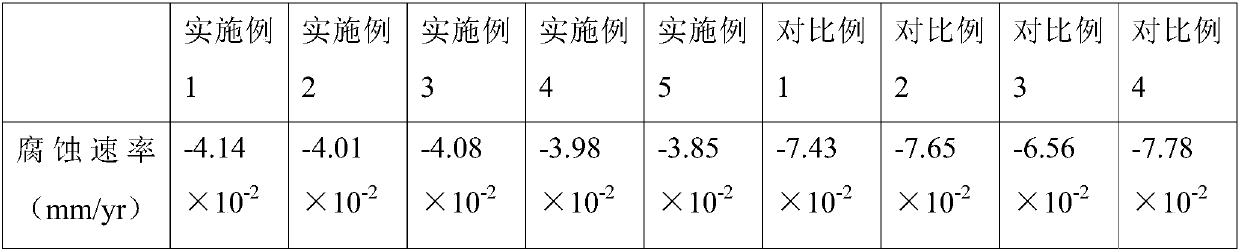

Examples

Embodiment 1

[0028] A kind of nickel base alloy powder, its preparation method comprises the following steps:

[0029] (1) In terms of mass percentage, the nickel-based alloy powder components are: magnesium 2%, cobalt 8%, chromium 12%, molybdenum 1.2%, Re 0.3%, silicon 4%, carbon 0.8%, boron 0.6%, iron 2.6%, aluminum 2.15%, the rest is nickel;

[0030] Weigh the following components according to the above mass percentages: anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate, Re, silicon dioxide, flake graphite powder, boron powder, iron powder, di Aluminum and nickel nitrate hexahydrate;

[0031] (2) Anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate and nickel nitrate hexahydrate are mixed, then add water and mix with mixture and water weight ratio is 1:8;

[0032] (3) Heat the product obtained in step (2) to 70°C, add 0.01 times the weight of ammonia w...

Embodiment 2

[0039] A kind of nickel base alloy powder, its preparation method comprises the following steps:

[0040] (1) In terms of mass percentage, the nickel-based alloy powder components are: magnesium 4.35%, cobalt 15%, chromium 17.35%, molybdenum 2.6%, Re 0.6%, silicon 6%, carbon 1.5%, boron 1.8%, iron 3.2% %, aluminum 3.85%, the rest is nickel;

[0041] Weigh the following components according to the above mass percentages: anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate, Re, silicon dioxide, flake graphite powder, boron powder, iron powder, di Aluminum and nickel nitrate hexahydrate;

[0042] (2) Anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate and nickel nitrate hexahydrate are mixed, then add water and mix with mixture and water weight ratio is 3:10;

[0043] (3) Heat the product obtained in step (2) to 80°C, add 0.02 times the weight of...

Embodiment 3

[0050] A kind of nickel base alloy powder, its preparation method comprises the following steps:

[0051] (1) In terms of mass percentage, the nickel-based alloy powder components are: magnesium 3%, cobalt 10%, chromium 14%, molybdenum 1.6%, Re 0.4%, silicon 4.5%, carbon 1.0%, boron 1.0%, iron 2.8%, aluminum 2.85%, the rest is nickel;

[0052] Weigh the following components according to the above mass percentages: anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate, Re, silicon dioxide, flake graphite powder, boron powder, iron powder, di Aluminum and nickel nitrate hexahydrate;

[0053] (2) Anhydrous magnesium sulfate, cobalt nitrate hexahydrate, chromium nitrate nonahydrate, molybdenum nitrate pentahydrate and nickel nitrate hexahydrate are mixed, then add water to mix with mixture and water weight ratio of 1:9;

[0054] (3) Heat the product obtained in step (2) to 75°C, add 0.012 times the weight of ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com