Lithium-sulfur battery electrolyte and preparation method thereof and battery using lithium-sulfur battery electrolyte

A lithium-sulfur battery and electrolyte technology, which is applied in the field of preparation of the electrolyte, can solve the problems that cycle performance and specific capacity cannot be taken into account, polysulfide dissolution cannot be prevented, and the effect of improving the specific capacity of the cycle performance battery is not obvious. , to achieve the effects of improving Coulombic efficiency and cycle performance, improving discharge specific capacity and cycle stability, and improving capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Electrolyte and its preparation

[0031] in an argon atmosphere glove box (H 2 O<0.1ppm), the organic solvent is mixed with LiTFSI (1.0M) at a volume ratio of 1,3-dioxolane (DOL): ethylene glycol dimethyl ether (DME) = 1:1, and the total mass of 2 % of dimethyl diselenide, fully stirred evenly to obtain the lithium-sulfur battery electrolyte of the present invention.

[0032] (2) Preparation of positive pole piece

[0033] Mix the sulfur / activated carbon composite material, carbon black and polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1:1, then add an appropriate amount of N-methylpyrrolidone (NMP) dropwise, and then perform ball milling Mixing, wherein the number of revolutions of the ball mill is 200 rpm, and the ball milling time is 4 hours. Spread the ball-milled slurry evenly on the aluminum foil, and perform vacuum drying at a drying temperature of 60 degrees Celsius for 4 hours to obtain the positive electrode material.

[0034] (3) Pre...

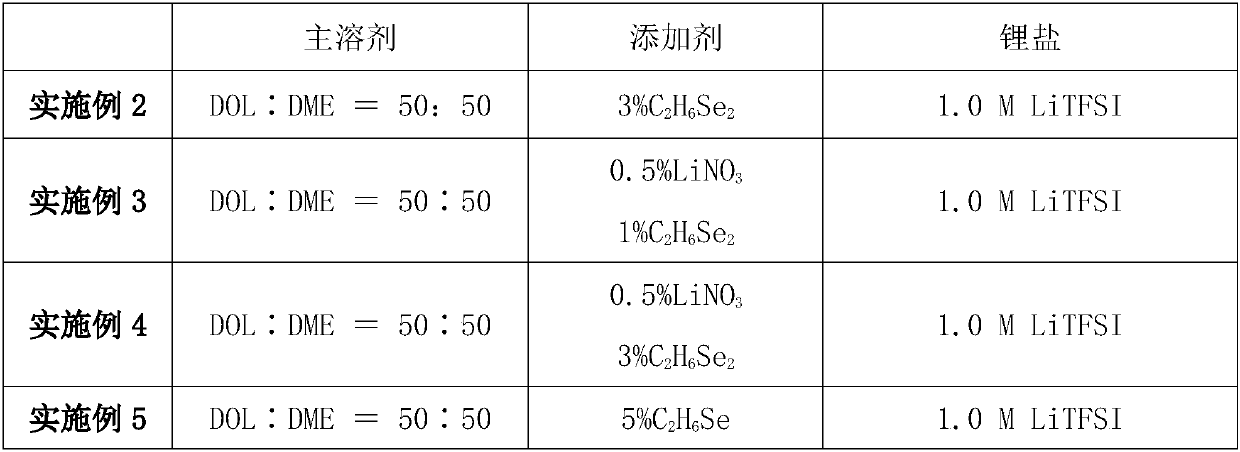

Embodiment 2-8

[0041] Except the parameters in the following table, other parameters and preparation method are the same as in Example 1.

[0042] Table 1 Example 2-8

[0043]

[0044]

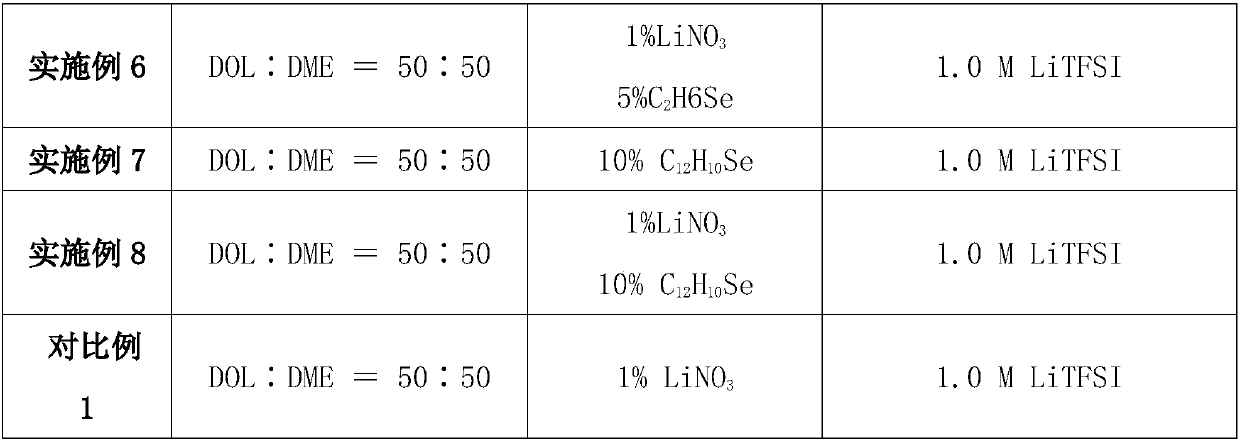

[0045] The test result of table 2 embodiment and comparative example

[0046]

[0047] Embodiments 1 to 8 are compared with comparative example 1, and comparative example 1 is under the discharge rate of 0.5C, and the first cycle discharge specific capacity is

[0048] 602mAh / g, which is 214mAh / g-363mAh / g less than the first-cycle discharge specific capacity in Examples 1 to 8, and the cycle performance is also 29.7%-55.5% lower than that in Examples 1-8, and the Coulombic efficiency is also low 0.8% to 2%, it can be seen that the selenide additive significantly improves the discharge specific capacity, cycle performance and coulombic efficiency of the battery.

Embodiment 9

[0050] (1) Preparation of electrolyte

[0051] in an argon atmosphere glove box (H 2 O3 CF 3 (0.5M) and mix, add 0.5% dimethyl diselenide and 0.5% lithium nitrate in total mass, and fully stir evenly to obtain the lithium-sulfur battery electrolyte of the present invention.

[0052] (2) Preparation of positive electrode sheet for lithium-sulfur battery

[0053] Mix the carbon-coated lithium sulfide composite material, carbon black and polyvinylidene fluoride (PVDF) according to the mass ratio of 8:1:1, then add an appropriate amount of N-methylpyrrolidone (NMP) dropwise, and then carry out Ball milling the mixture, wherein the number of revolutions of the ball mill is 200 rpm, and the ball milling time is 4 hours. Spread the ball-milled slurry evenly on the aluminum foil, and carry out vacuum drying at a drying temperature of 60 degrees Celsius and a drying time of 4 hours to obtain the positive electrode material. This process is completed in a drying room with a drying de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com