Leveling agent for powdered coating and preparation method of leveling agent

A powder coating and leveling agent technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of thin liquid coatings, and achieve the effects of low polarizability, low surface energy, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

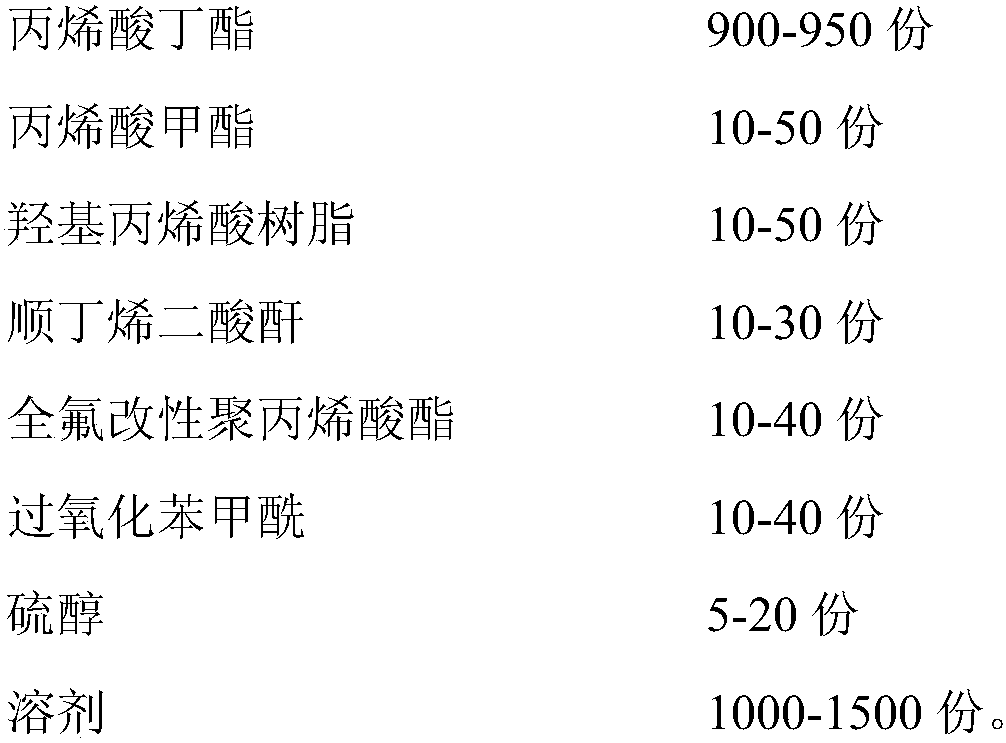

[0022] The composition of raw materials is as follows:

[0023]

[0024] The preparation method is as follows:

[0025] (1) Add 500 parts of toluene and butyl acrylate into the reactor, start stirring and heating to reflux;

[0026] (2) Add the remaining toluene, methyl acrylate, hydroxyethyl acrylate, maleic anhydride, perfluorinated polyacrylate, benzoyl peroxide and mercaptan into the dropping tank and mix evenly. Add dropwise for 2 hours;

[0027] (3) Then keep the temperature at 110° C. for 6 hours, distill under reduced pressure to extract the solvent, and obtain the leveling agent 1 .

Embodiment 2

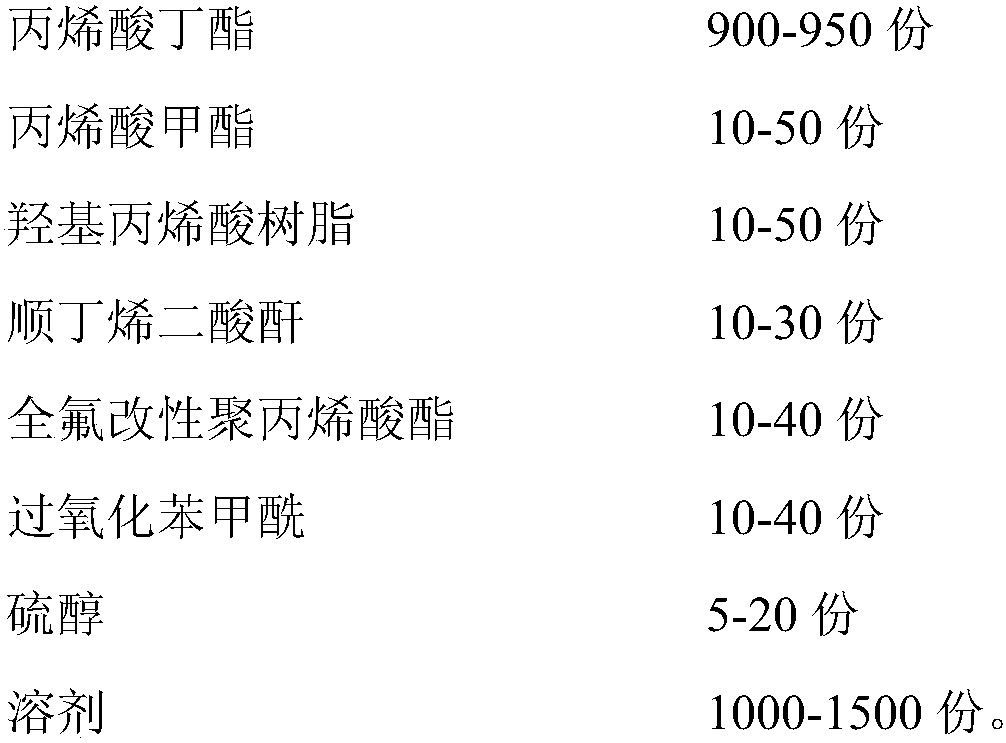

[0029] The composition of raw materials is as follows:

[0030]

[0031] The preparation method is as follows:

[0032] (1) Add 800 parts of toluene and butyl acrylate into the reactor, start stirring and heating to reflux;

[0033] (2) Add the remaining toluene, methyl acrylate, hydroxypropyl acrylate, maleic anhydride, perfluorinated polyacrylate, benzoyl peroxide and mercaptan into the dropping tank and mix evenly. Add dropwise for 2 hours;

[0034] (3) Then keep the temperature at 115° C. for 3 hours, distill under reduced pressure to extract the solvent, and obtain the leveling agent 2 .

Embodiment 3

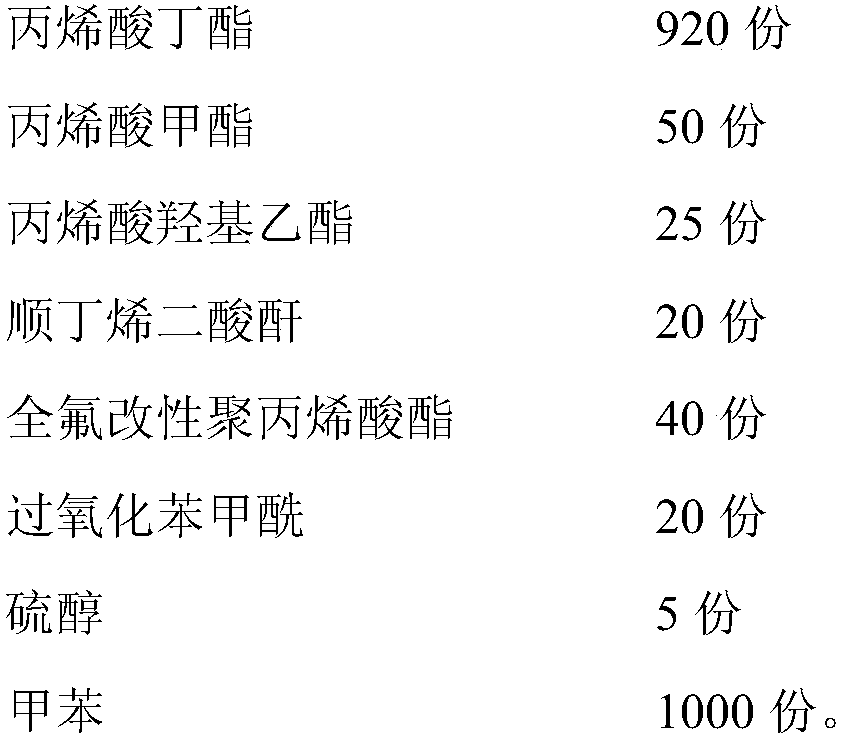

[0036] The composition of raw materials is as follows:

[0037]

[0038] The preparation method is as follows:

[0039] (1) Add 700 parts of toluene and butyl acrylate into the reactor, start stirring and heating to reflux;

[0040] (2) Add the remaining toluene, methyl acrylate, hydroxypropyl acrylate, maleic anhydride, perfluorinated polyacrylate, benzoyl peroxide and mercaptan into the dropping tank and mix evenly. Add dropwise for 2 hours;

[0041] (3) Then keep the temperature at 112° C. for 5 hours, distill under reduced pressure to extract the solvent, and obtain the leveling agent 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com