A kind of electrochemical preparation method of nano-flaky bismuth fluoride thin film and its application

A nano-flaky, bismuth fluoride technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as high energy consumption and complicated film immobilization technology, and achieve uniform dispersion, The effect of short cycle and process environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the first step, configure 300 mL of mixed solution A with a volume ratio of 20:1 ethylene glycol and distilled water, and weigh 4.57 g of analytically pure NH 4 F is placed in solution A, fully stirred to make it completely dissolved, as solution B;

[0026] In the second step, use 400-mesh abrasive paper to smooth the 4 cm × 1.5 cm × 0.5 cm eraser, rinse the polished eraser with absolute ethanol and distilled water, and set aside;

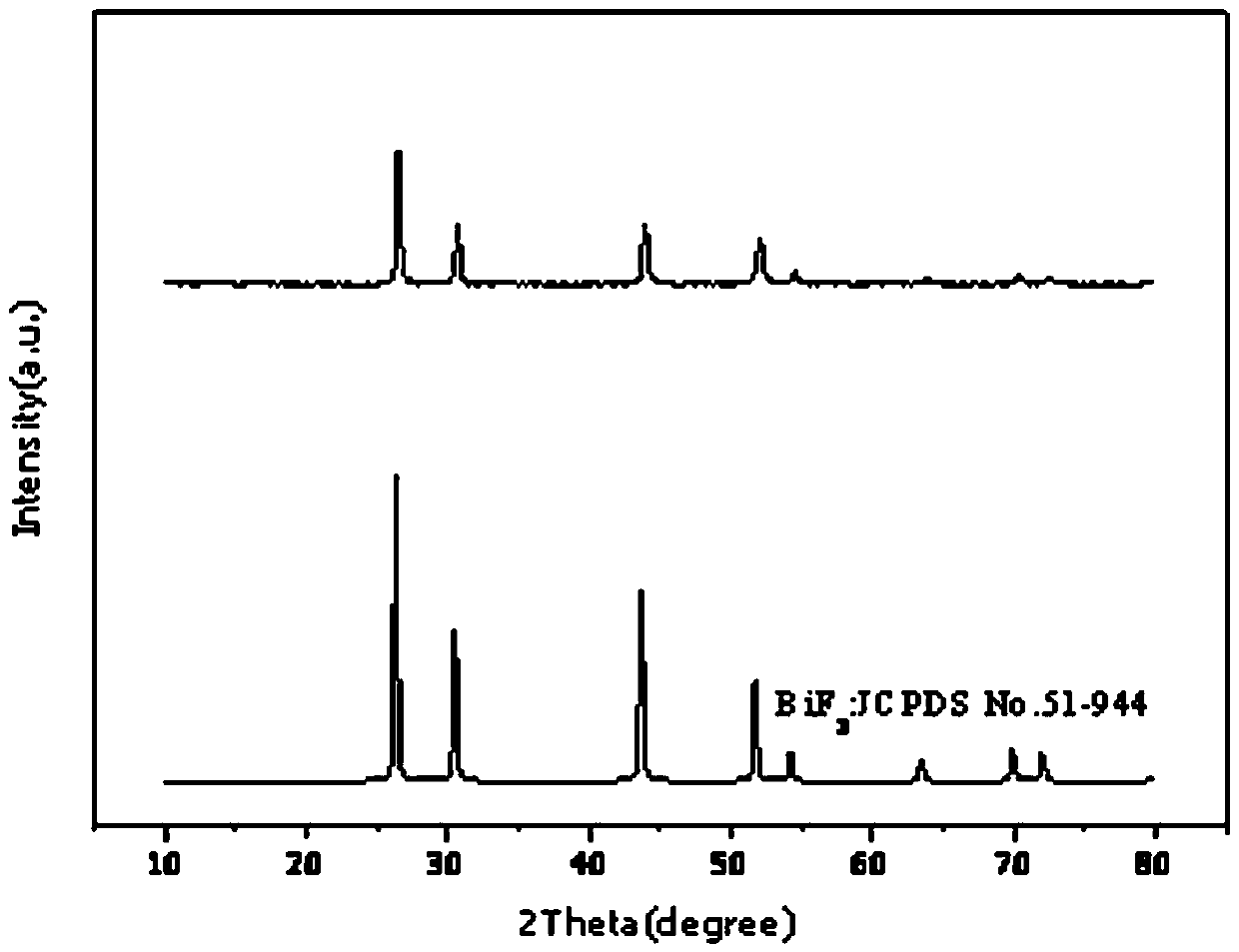

[0027] In the third step, the Bi plate in the second step is used as the anode, the graphite is used as the cathode, the distance between the cathode and the anode electrodes is 5 cm, and solution B is used as the electrolyte. After deposition at 60 V for 0.5 h, the Bi plate is taken out and dried naturally to obtain Nanosheet BiF 3 Thin film, denoted as BiF 3 -1.

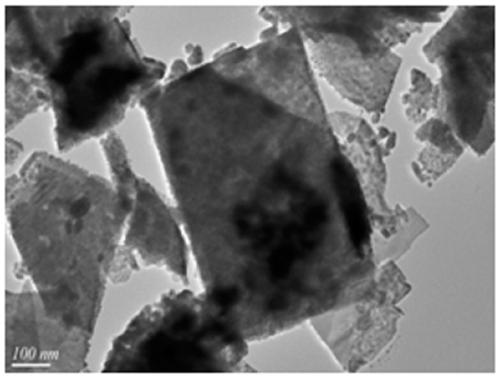

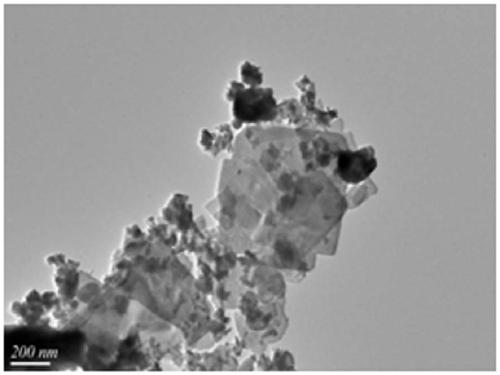

[0028] It was shown by scanning electron microscope that the BiF prepared in this example 3 The film has a sheet-like morphology.

Embodiment 2

[0030] In the first step, prepare 200 mL of mixed solution A with a volume ratio of 15:1 ethylene glycol and distilled water, and weigh 1.1 g of analytically pure NH 4 F is placed in solution A, fully stirred to make it completely dissolved, as solution B;

[0031] In the second step, use 400-mesh abrasive paper to smooth the 4 cm × 1.5 cm × 0.5 cm eraser, rinse the polished eraser with absolute ethanol and distilled water, and set aside;

[0032] 3) The Bi plate in the second step was used as the anode, the graphite was used as the cathode, the distance between the cathode and the anode was 2 cm, and solution B was used as the electrolyte. After deposition at 40 V for 2 h, the Bi plate was taken out and dried naturally to obtain nanosheets BiF 3 Thin film, denoted as BiF 3 -2.

Embodiment 3

[0034] In the first step, prepare 100 mL of mixed solution A with a volume ratio of 1:20 ethylene glycol and distilled water, and weigh 1 g of analytically pure NH 4 F is placed in solution A, fully stirred to make it completely dissolved, as solution B;

[0035] In the second step, use 400-mesh abrasive paper to polish the 4 cm × 1.5 cm × 0.5 cm Bi board smoothly, rinse the polished Bi board with solution A in the first step, and set it aside;

[0036] In the third step, the Bi plate in the second step is used as the anode, the graphite is used as the cathode, the distance between the cathode and the anode is 8 cm, and the solution B is used as the electrolyte. After deposition at a voltage of 30 V for 3 h, the Bi plate is taken out and dried naturally to obtain Nanosheet BiF 3 Thin film, denoted as BiF 3 -3.

[0037] BiF 3 The film was applied to the photocatalytic degradation of Rhodamine B.

[0038] Accurately weigh 10 mg of Rhodamine B, put it into a 1000 mL quantita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com