Hairtail protein peptide nutrient milk powder and preparation method thereof

A technology of protein peptides and hairtail, applied to milk preparations, bacteria used in food preparation, dairy products, etc., to reduce costs, ensure safety, and improve nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

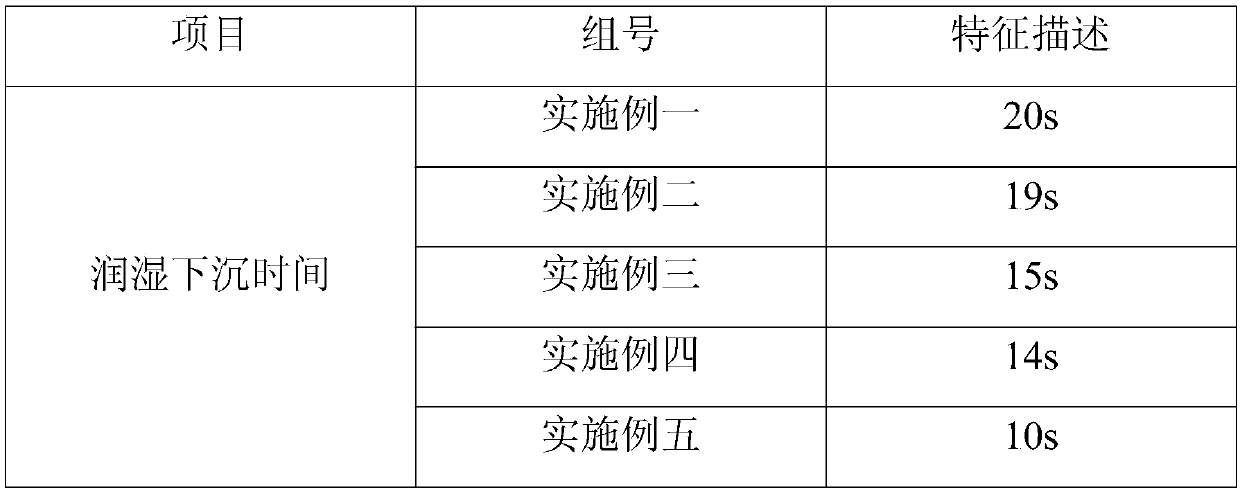

Examples

preparation example Construction

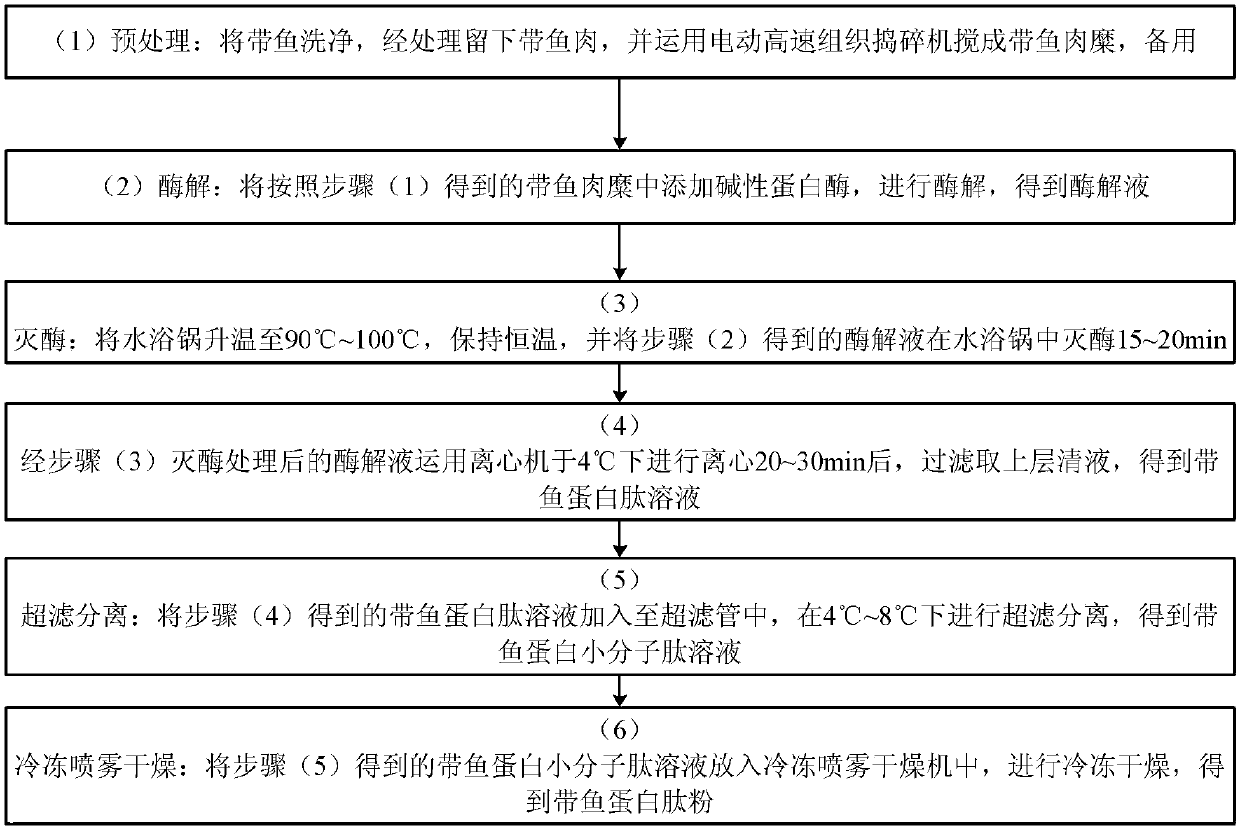

[0048] The preparation method of the hairtail protein peptide powder comprises the following steps:

[0049] (1) Pretreatment: Wash the hairtail, remove the head, tail, and viscera, and remove the hairtail bones to leave the hairtail meat. Mix the hairtail meat and water according to the water-to-material ratio of 1:3, and use an electric high-speed tissue grinder Stir into hairtail meat mince, set aside;

[0050] (2) Enzymolysis: add alkaline protease to 1.6% of the weight of hairtail minced meat obtained in step (1), and enzymolyze it in a water bath at 50° C. for 4 hours to obtain an enzymolysis solution;

[0051](3) Enzyme inactivation: raise the temperature of the water bath to 90°C, keep the temperature constant, and inactivate the enzyme solution obtained in step (2) in the water bath for 15 minutes;

[0052] (4) Centrifugation and filtration: the enzymatic hydrolysis solution after the enzyme-inactivating treatment in step (3) is centrifuged at 4000r / min and 4°C for 2...

Embodiment 1

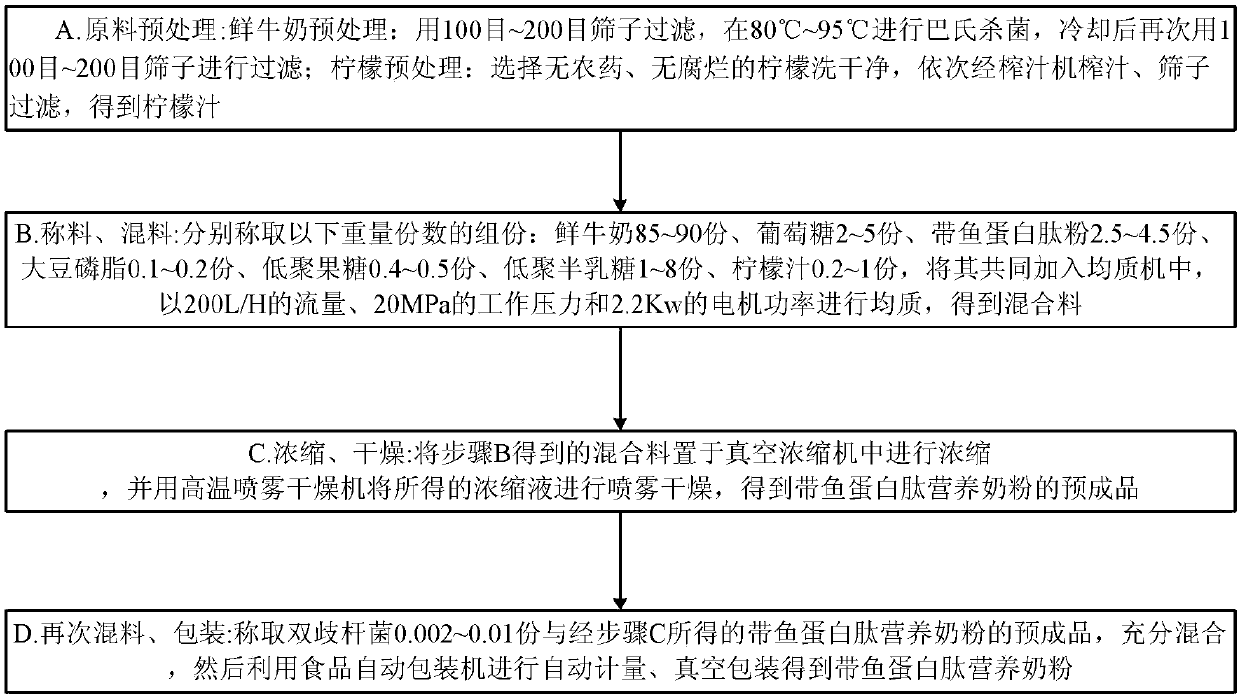

[0057] A. Raw material pretreatment

[0058] Fresh milk pretreatment: filter with a 100-200-mesh sieve, pasteurize at 80°C-95°C, and filter again with a 100-200-mesh sieve after cooling;

[0059] Lemon pretreatment: select pesticide-free and non-rotten lemons, wash them, squeeze the juice through a juicer, and filter through a sieve to obtain lemon juice;

[0060] B. Weighing and mixing

[0061] Weigh the following components in parts by weight: 3 parts of glucose, 2.5 parts of hairtail protein peptide powder, 0.2 part of soybean lecithin, 0.45 part of fructo-oligosaccharide, 2 parts of galacto-oligosaccharide, 0.2 part of lemon juice, and the rest is milk. They are jointly added to the homogenizer, and homogenized with a flow rate of 200L / H, a working pressure of 20MPa and a motor power of 2.2Kw to obtain a mixture;

[0062] C. Concentrate and dry

[0063] The mixture obtained in step B is placed in a vacuum concentrator, concentrated to 1 / 4 of the original volume, and the...

Embodiment 2

[0067] A. Raw material pretreatment

[0068] Fresh milk pretreatment: filter with a 100-200-mesh sieve, pasteurize at 80°C-95°C, and filter again with a 100-200-mesh sieve after cooling;

[0069] Lemon pretreatment: select pesticide-free and non-rotten lemons, wash them, squeeze the juice through a juicer, and filter through a sieve to obtain lemon juice;

[0070] B. Weighing and mixing

[0071] Weigh the following components in parts by weight: 3 parts of glucose, 3 parts of hairtail protein peptide powder, 0.2 part of soybean lecithin, 0.45 part of fructo-oligosaccharide, 2 parts of galacto-oligosaccharide, 0.4 part of lemon juice, and the rest is milk. They are jointly added to the homogenizer, and homogenized with a flow rate of 200L / H, a working pressure of 20MPa and a motor power of 2.2Kw to obtain a mixture;

[0072] C. Concentrate and dry

[0073] The mixture obtained in step B is placed in a vacuum concentrator, concentrated to 1 / 4 of the original volume, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com