Method for harmlessly treating municipal sludge

A technology for harmless treatment of municipal sludge, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of high cost, unsatisfactory treatment effect and energy consumption Advanced problems, to achieve the effect of low cost, significant cost-efficiency advantages, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

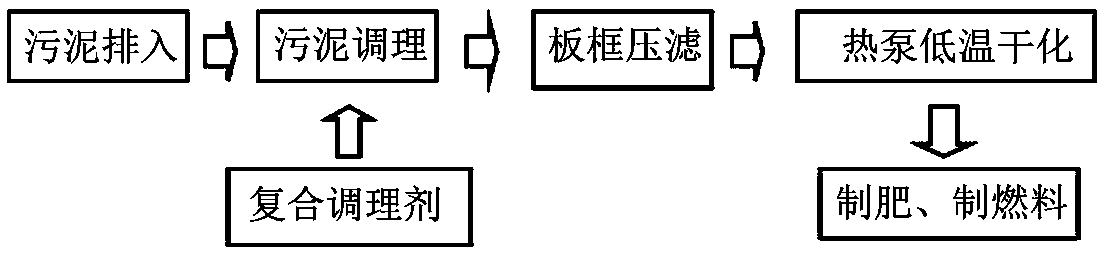

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of municipal sludge harmless treatment method comprises the following steps:

[0031] (1) Sludge conditioning: discharge the sludge to be treated into the conditioning tank, add the compound conditioner to it and stir; the amount of the compound conditioner added is 1% of the mass of the absolute dry sludge based on the amount of absolute dry sludge %.

[0032] The composite conditioner is made of the following raw materials in parts by weight: 30 parts of cetyltrimethylammonium chloride, 2 parts of guar gum hydroxypropyltrimethylammonium chloride, 10 parts of zeolite powder, and 0.1 part of citric acid , 58 parts of water; wherein the particle size of the zeolite powder is 300 mesh.

[0033] The preparation method of this composite conditioner is:

[0034] A. Dissolve cetyltrimethylammonium chloride in water, add zeolite powder, and stir for 2 hours at a temperature of 60°C;

[0035] B. add guar gum hydroxypropyl trimethylammonium chloride in th...

Embodiment 2

[0041] Embodiment 2: a kind of municipal sludge harmless treatment method, the difference with embodiment 1 is that the composite conditioner used is made of the following raw materials in parts by weight: cetyltrimethylammonium chloride 25 3 parts of guar gum hydroxypropyltrimethylammonium chloride, 12 parts of zeolite powder, 0.2 parts of citric acid, and 60 parts of water. The addition amount of the composite conditioner is 2% of the absolute dry sludge mass.

Embodiment 3

[0042] Embodiment 3: A kind of municipal sludge harmless treatment method, the difference from embodiment 1 is that the compound conditioner used is made of the following raw materials in parts by weight: cetyltrimethylammonium chloride 35 1.5 parts of guar gum hydroxypropyltrimethylammonium chloride, 8 parts of zeolite powder, 0.15 parts of citric acid, and 55 parts of water. The addition amount of the composite conditioner is 0.5% of the absolute dry sludge mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com