High-temperature-self-crosslinked modified waterborne polyurethane resin and preparation method thereof

A water-based polyurethane and self-crosslinking technology, applied in the field of high-temperature self-crosslinking modified water-based polyurethane resin, can solve the problems of weak adhesion and lack of tear strength, and achieve the effect of avoiding short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

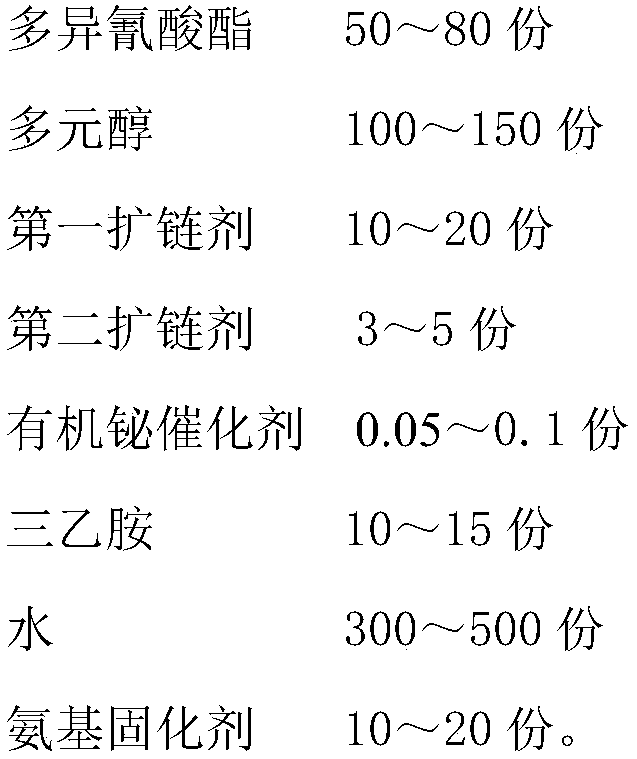

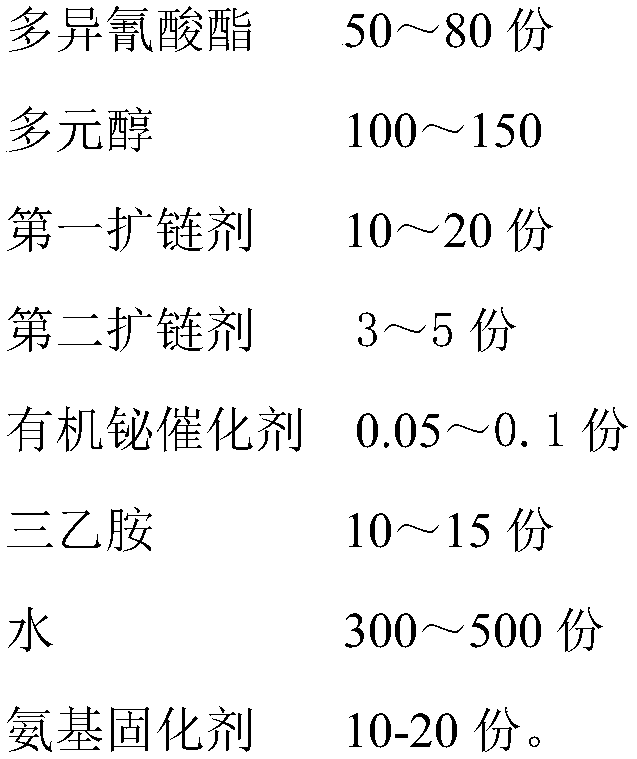

Method used

Image

Examples

Embodiment 1

[0034] Take 10kg toluene diisocyanate, 10kg isophorone diisocyanate, 10kg diphenylmethane diisocyanate, 10kg1,6-hexamethylene diisocyanate, 10kg xylylene diisocyanate, 10kg naphthalene-1,5-diisocyanate, 5kg Polymethylene polyphenyl isocyanate, 5kg tetramethylxylylene diisocyanate, 5kg methylcyclohexyl diisocyanate, 5kg dicyclohexylmethane diisocyanate, 20kg polycaprolactone polyol, 20kg polycarbonate polyol Alcohol, 20kg polytetrahydrofuran ether polyol, 20kg polyethylene oxide polyol, 20kg polypropylene oxide polyol, 20kg hydroxyl-terminated polybutadiene, 20kg polysiloxane polyol and 10kg polyester ether polyol at 85~ React at 95°C for 2 to 3 hours; add 5kg dimethylolpropionic acid, 5kg dimethylolbutyric acid, 5kg dimethylolvaleric acid, 5kg dimethylol octanoic acid, 1kg ethylene glycol, 1kg diethylene acetal Diol, 1kg 1,4-butanediol, 1kg 2,3-butanediol and 1kg 1,6-hexanediol, and at the same time add an appropriate amount of acetone to react at 75-85°C for 1-3 hours; then a...

Embodiment 2

[0036] Take 25kg toluene diisocyanate, 25kg isophorone diisocyanate, 20kg lactone diol, 20kg polycarbonate diol, 20kg polytetrahydrofuran ether diol, 10kg polyethylene oxide diol, 10kg polycyclic Propylene oxide diol, 10kg hydroxyl-terminated polybutadiene and 10kg polysiloxane diol react at 85-95°C for 2-3 hours; add 5kg dimethylolpropionic acid, 5kg dimethylolbutyric acid, 2kg of ethylene glycol and 2kg of diethylene glycol, and at the same time add an appropriate amount of acetone to react at 75-85°C for 1-3 hours; then add 0.05kg of Coscat83 and 0.05kg of organic bismuth 1610 and react at 65-75°C for 2-3 hours; Cool down to 35-45°C, add 10kg of amino curing agent, and add 10kg of triethylamine to neutralize; finally add 300kg of water, react the obtained product at 85-95°C for 2-3 hours, remove acetone in vacuum to obtain the water-based polyurethane resin.

Embodiment 3

[0038] Take 20kg toluene diisocyanate, 20kg isophorone diisocyanate, 20kg diphenylmethane diisocyanate, 40kg polycaprolactone polyol, 40kg polycarbonate polyol and 40kg polytetrahydrofuran ether polyol and react at 85-95°C for 2 ~3h; add 5kg dimethylolpropionic acid, 5kg dimethylolbutyric acid, 5kg dimethylolvaleric acid, 2kg ethylene glycol, 1kg diethylene glycol and 1kg1,4-butanediol, and simultaneously Add appropriate amount of acetone and react at 75-85°C for 1-3 hours; then add 0.02kg Coscat83, 0.02kg organic bismuth 1610 and 0.02kg organic bismuth 2010 and react at 65-75°C for 2-3 hours; cool down to 35-45°C and add 15kg Amino curing agent, and neutralized by adding 12kg of triethylamine; finally adding 400kg of water, the obtained product was reacted at 85-95°C for 2-3 hours, and the acetone was removed in vacuum to obtain the water-based polyurethane resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com